Elastic sheet mounting part

A technology for installing components and elastic sheets, applied in packaging, packaging recycling, sustainable packaging industries, etc., can solve the obstacles of elastic sheets changing connection relationship, without comprehensive consideration of elastic sheets, and elastic sheets cannot be installed in place. materials, etc., to achieve stable installation effect and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The first embodiment of the present invention.

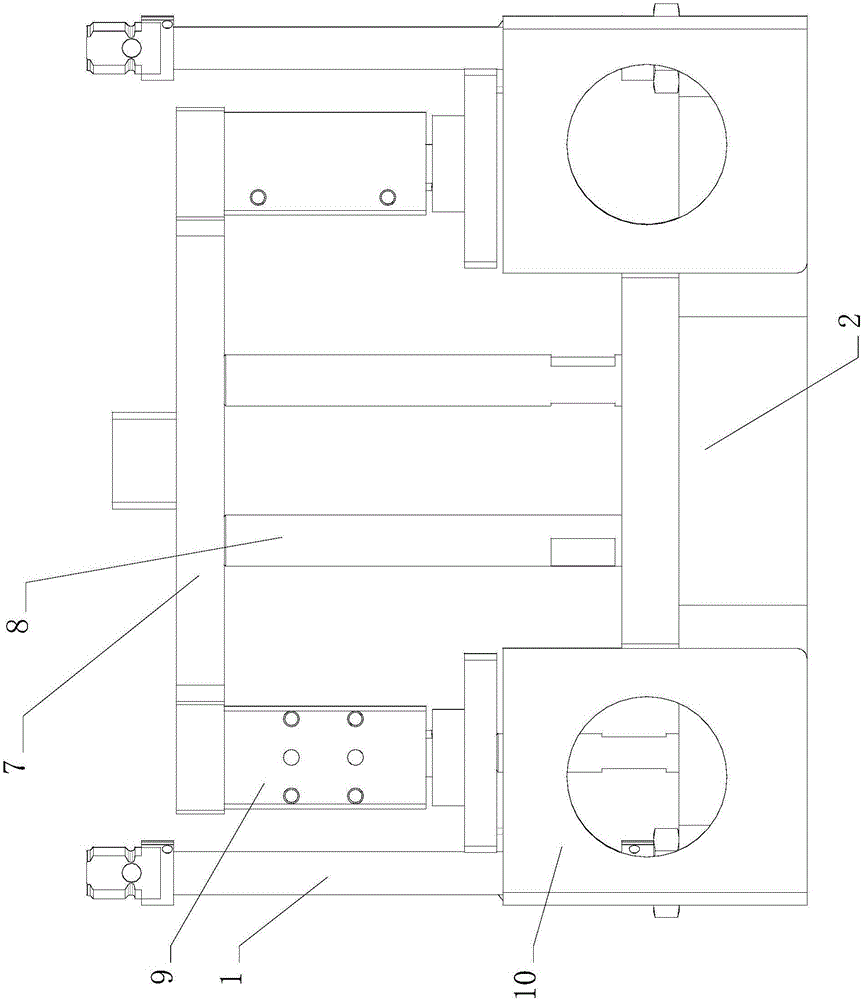

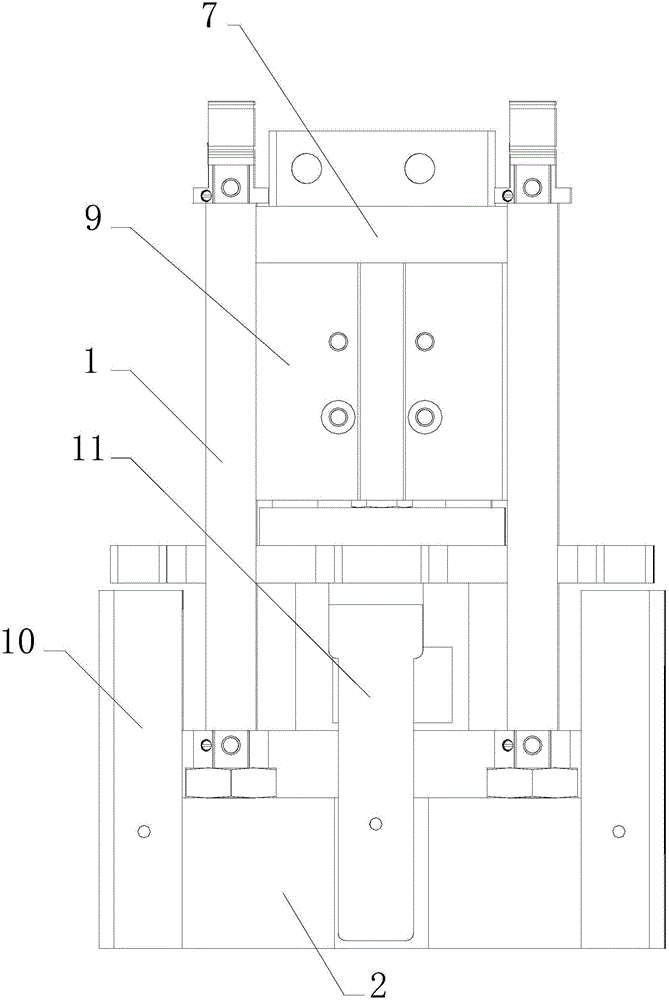

[0019] Such as figure 1 , 4 As shown, the elastic sheet installation part mainly includes the adsorption component, the push component I, the push component II1, and the push component I and the push component II1 are all installed on the adsorption component.

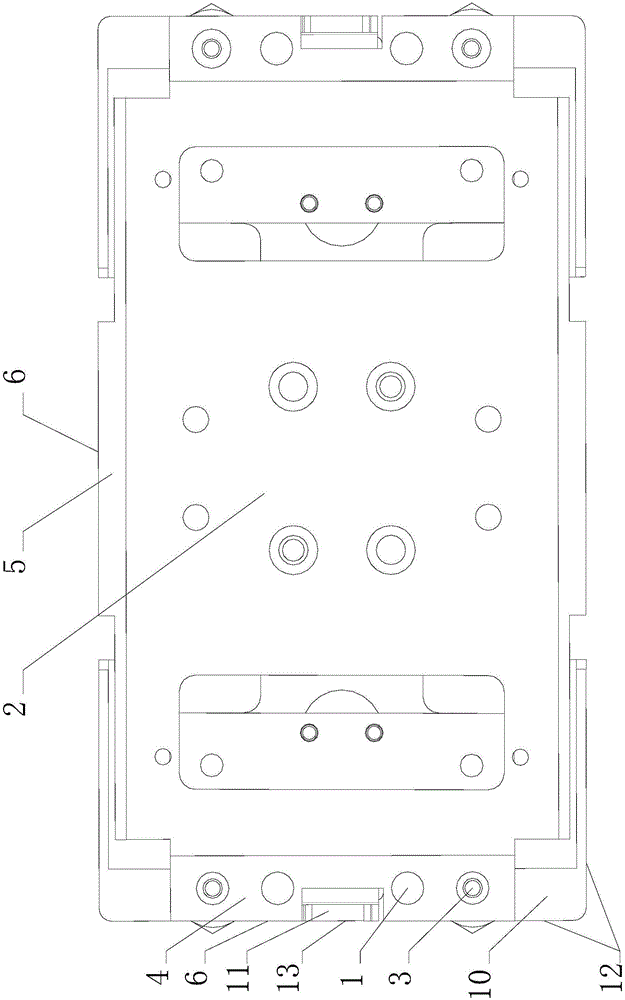

[0020] Such as image 3 , 4 The adsorption assembly includes a shaped template 2, a suction cup 3 and a bracket. The shaping formwork 2 has a flat cuboid structure as a whole, and a concave structure area is provided on the side with the largest surface area. This area is a storage area for accommodating the operation object, that is, the bent and formed elastic sheet. Because the shaped formwork 2 is provided with a storage area, an installation site I4 is formed at the position of its wide side, and the two installation positions I4 are in a symmetrical positional relationship with respect to the center line of the shaped formwork 2; Each position forms an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com