Enamel barrel baking rotating connection platform and operation method thereof

A transfer table and enamel technology, which is applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of inconvenient placement of enamel barrels, bonding countertop products, and low placement efficiency, so as to reduce the probability of product scrapping and low cost , The effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

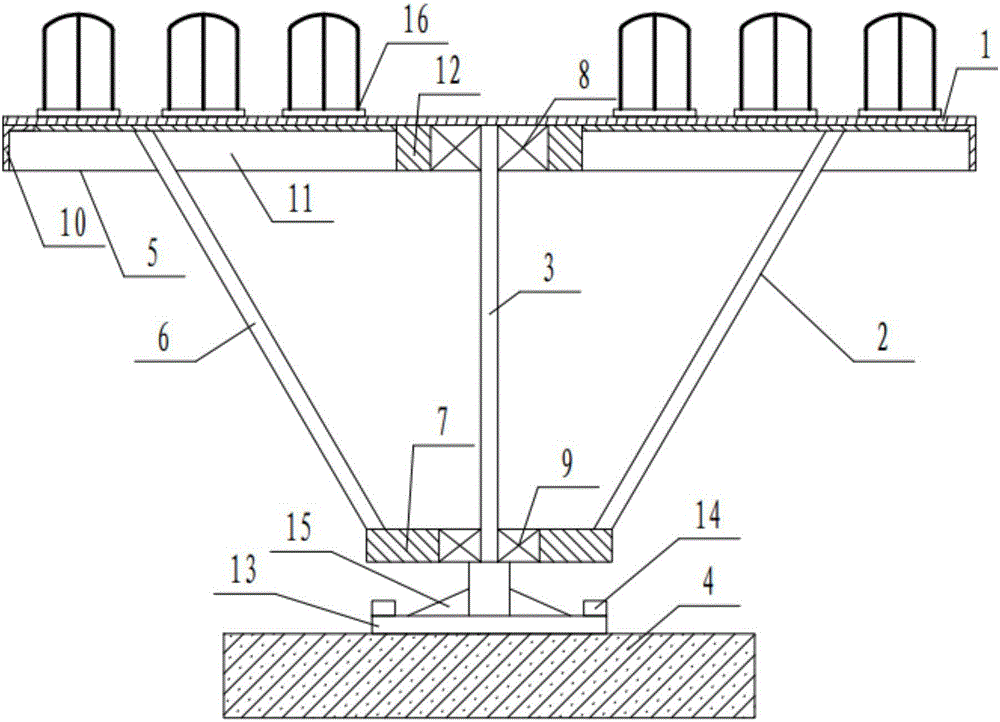

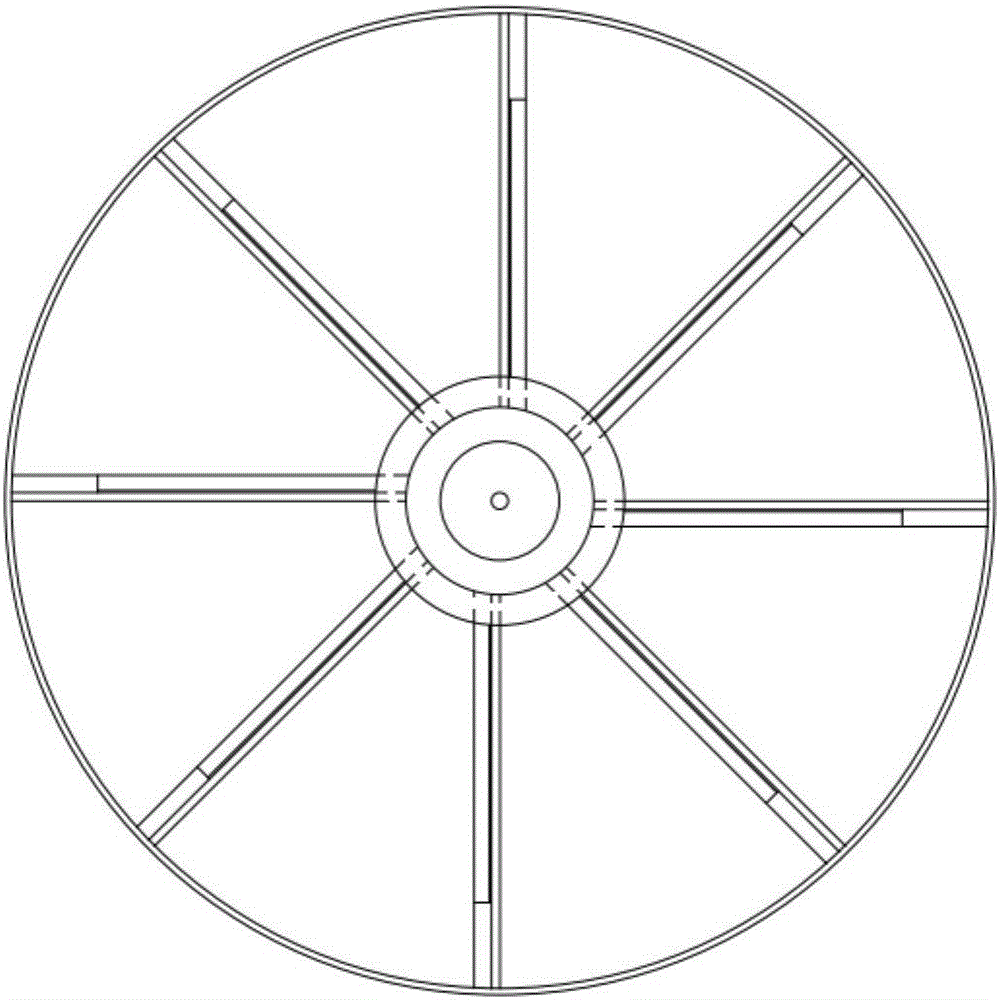

[0025] Embodiment 1: as Figure 1-Figure 6 As shown, an enamel barrel baking transfer table includes a cylindrical table top 1, a support frame 2 and a support frame 16, the bottom of the table top 1 is fixedly connected to the support frame 2, and the support frame 2 is rotatably connected to the rotating shaft 3 , the rotating shaft 3 is fixedly connected to the fixed table 4 next to the oven, and a plurality of support frames 16 are placed along the circumferential direction and the radial direction of the table top 1 .

[0026] Preferably, the table top 1 is made of thin steel skin.

[0027] Preferably, the support frame 2 includes a round frame top frame 5, a diagonal stay rod 6 and a chassis 7, the round frame top frame 5 is fixedly connected to the chassis 7 through the diagonal stay rods 6, and the whole is a cone frame structure, and the center of the round frame top frame 5 is provided with a Connect the top bearing 8 at the top of the rotating shaft, and the center...

Embodiment 2

[0034] Embodiment 2: An operation method of an enamel barrel baking transfer station, the method includes the following steps:

[0035] (1) Place the baked enamel bucket on the cooling table until its temperature is lower than 35 degrees Celsius;

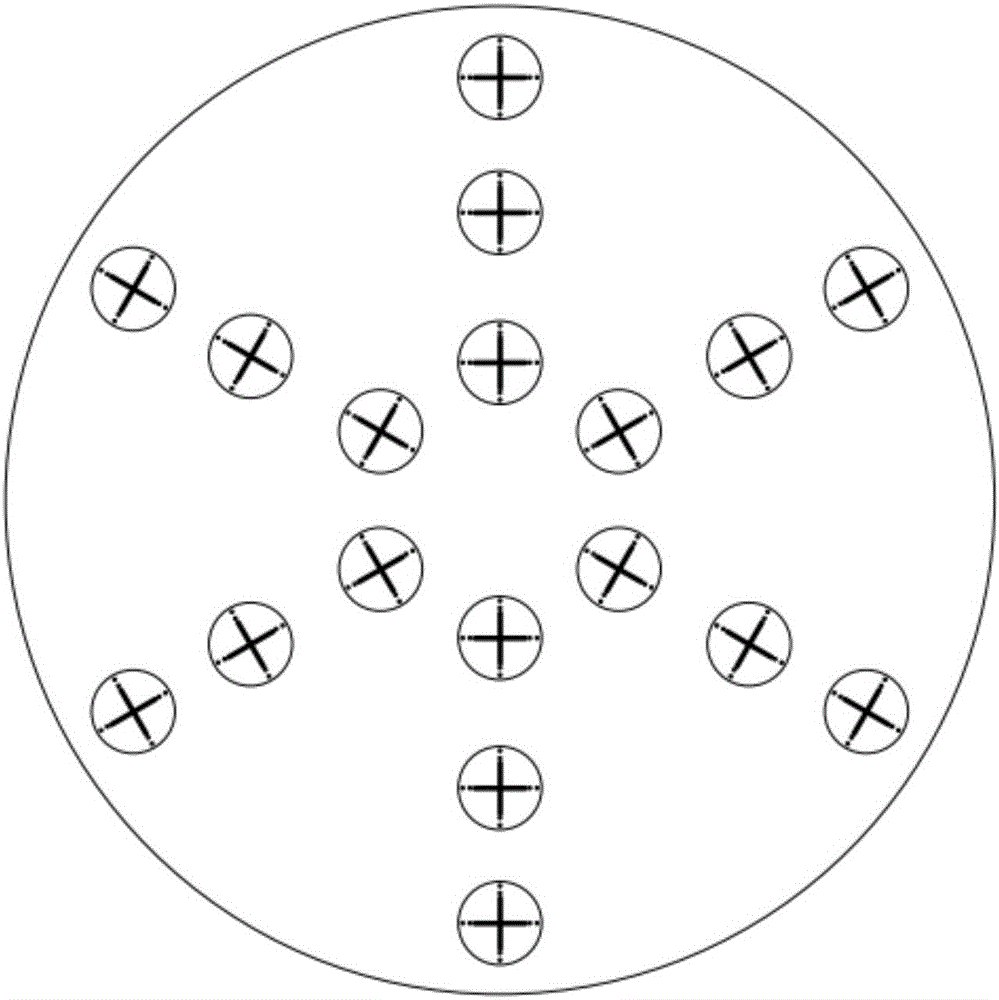

[0036] (2) After the temperature of the enamel barrel is lower than 35 degrees Celsius, place it on the support frame on the rotary table;

[0037] (3) Rotate the table at a constant speed, place the enamel barrels from the inner row to the outer row, and the enamel barrels will continue to put the outer row of enamel barrels after one rotation;

[0038] (4) When the enamel barrel is placed, pack the enamel barrel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com