Signal locking system for shaft machine operation at auxiliary shaft

A signal and auxiliary shaft technology, applied in mine lifting equipment, transportation and packaging, etc., can solve the problems of unsafe factors, crushing people in the tank, etc., achieve low production cost, ensure safe production, and maintain Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

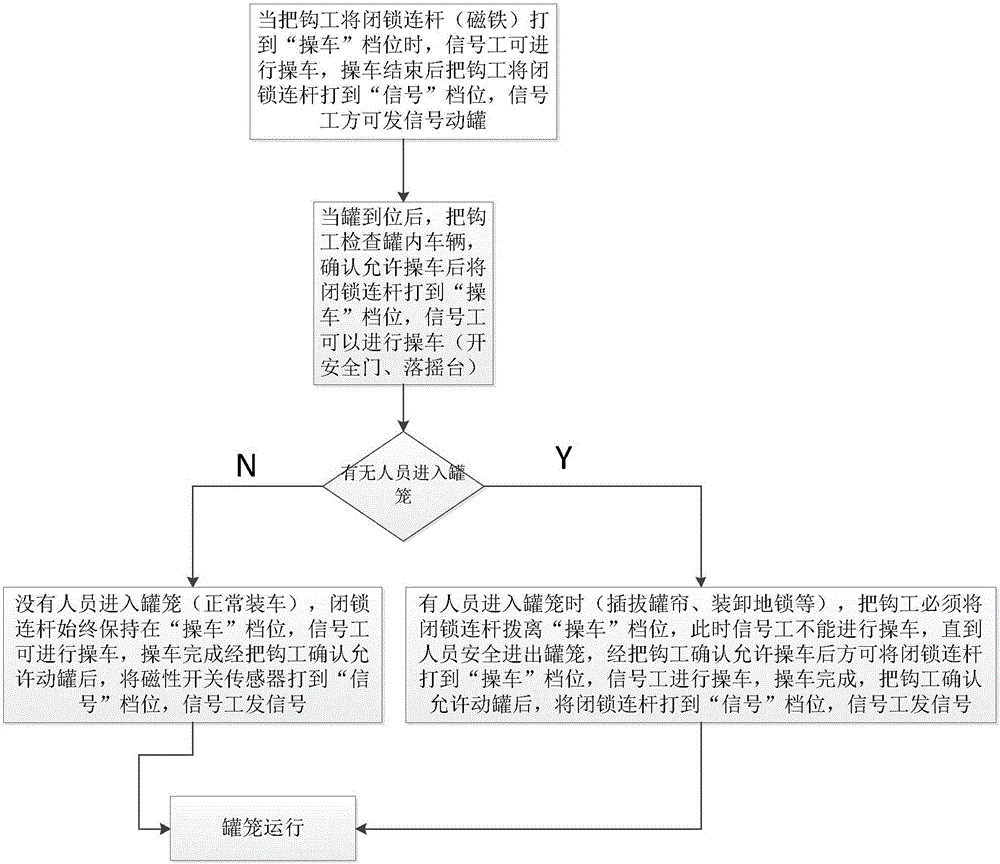

[0015] Such as figure 1 Shown: a driving signal locking system at the wellhead of an auxiliary well, including signal and driving locking devices, the signal and driving locking devices are installed at the upper and lower openings of the auxiliary well, and two sensors are connected in series to the signal and driving locking circuits respectively , as a vehicle operation, signal blocking, it includes the following steps:

[0016] (1) When the hooker turns the locking link (magnet) to the "operating" position, the signal worker can operate the car. After the operation is over, the hooker turns the locking link to the "signal" position. The signal worker can signal to move the tank;

[0017] (2) When the tank is in place, the hook worker checks the vehicle in the tank, and after confirming that the vehicle is allowed to operate, turn the locking link to the "driving" gear, and the signal worker can operate the vehicle (open the safety door, drop the cradle);

[0018] (3) If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com