A control method for a fold-down aerial work vehicle capable of preventing self-damage of the vehicle body

The technology of a high-altitude operation vehicle and a control method, which is applied in the field of aerial operation vehicles, can solve problems such as low work efficiency, large fixed-point quantity, and difficulty, and achieve the effects of improving work efficiency, high degree of automation, and preventing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

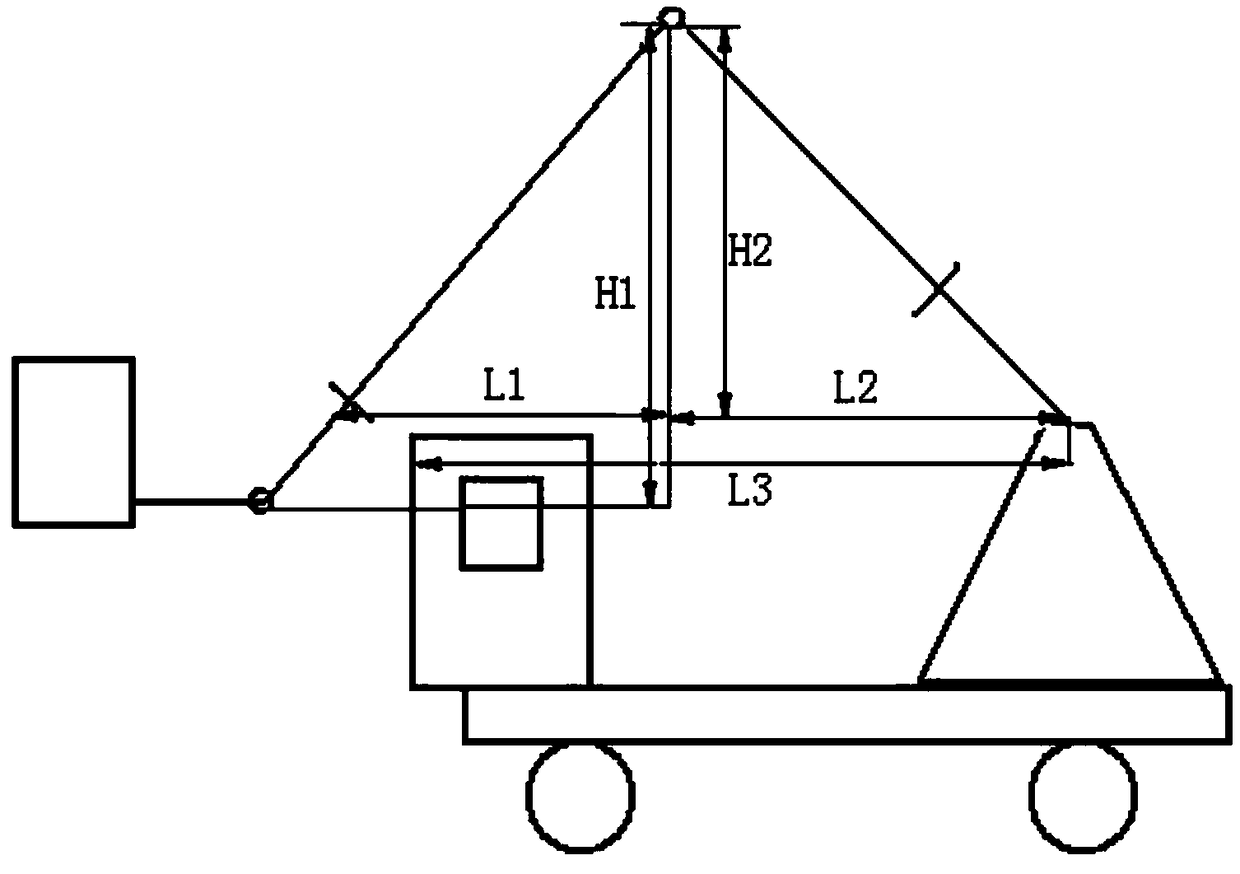

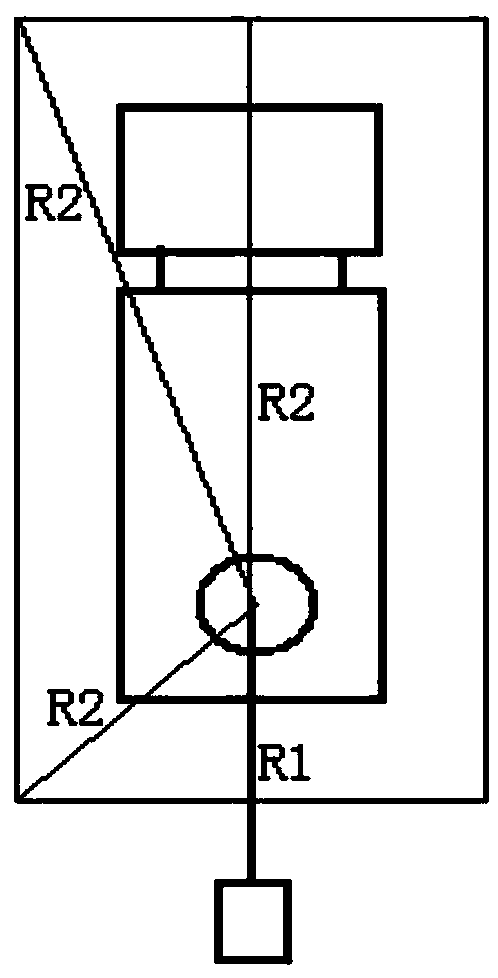

[0030] The present invention sets its own safety range for the down-folding aerial work vehicle, such as Figure 4 As shown, the position of the boom assembly 1 is calculated by collecting the attitude information of the down-folding aerial work vehicle through the controller 4, and by comparing the relationship between the position of the boom assembly 1 and its own safety range, the movement of certain booms is limited or allowed. motion trajectory, so as to achieve the purpose of preventing the boom assembly 1 from colliding with the vehicle body.

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

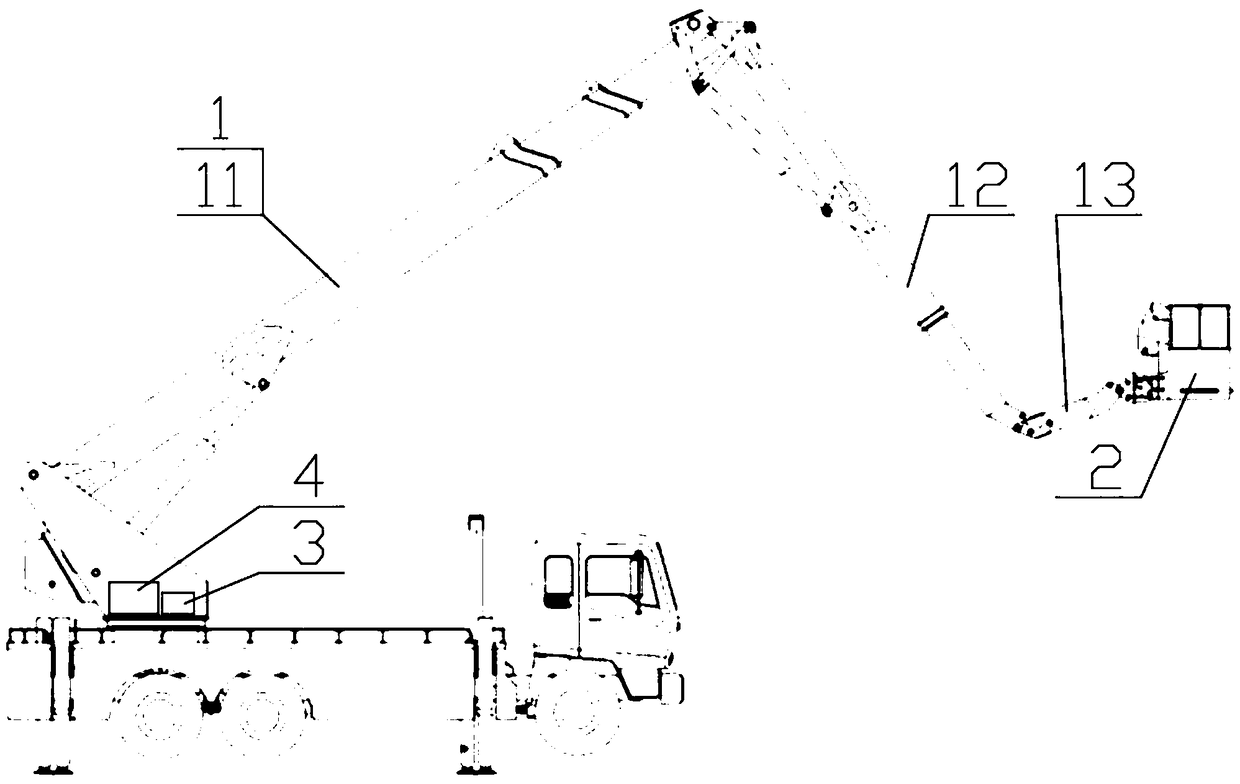

[0032] Such as figure 1 As shown, the down-folding aerial work vehicle used in the control method of the self-damage prevention of the vehicle body includes a car body assembly, a jib assembly 1, a working platform 2, and an action control hydraulic valve group 3 , Controller 4, jib inclination sensor, jib length senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com