Steel aluminum composite mould of high wading boot

A technology of steel-aluminum composite and water boots, which can be applied to home appliances, other home appliances, and household components, etc. It can solve the problems of not being able to meet the production needs of large orders in large factories, so as to avoid self-damage, take into account weight, and prevent pattern wear The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

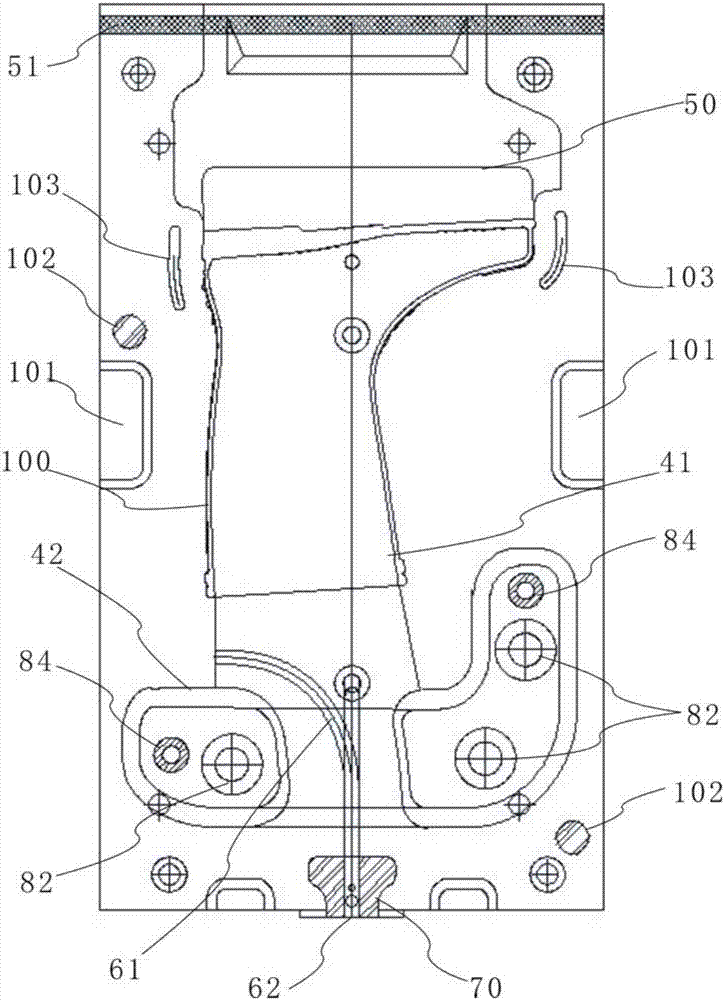

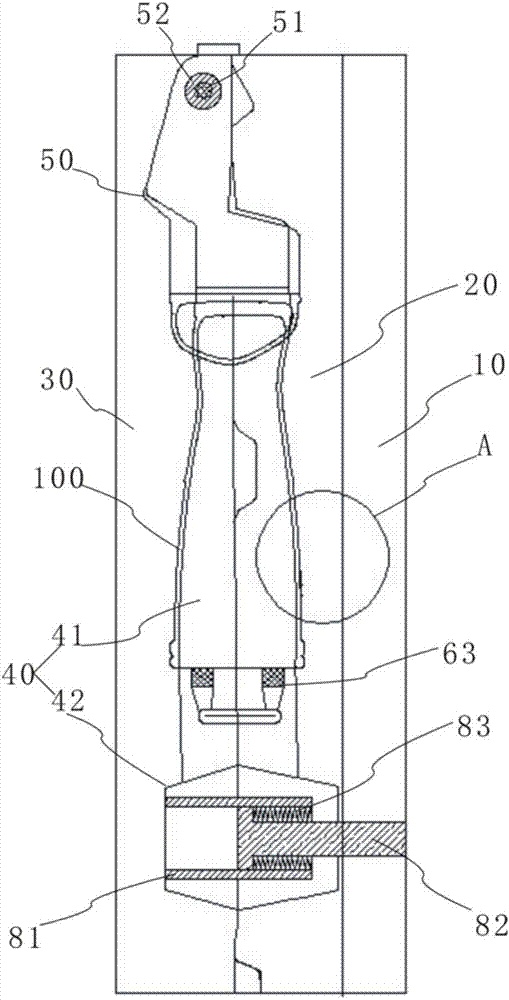

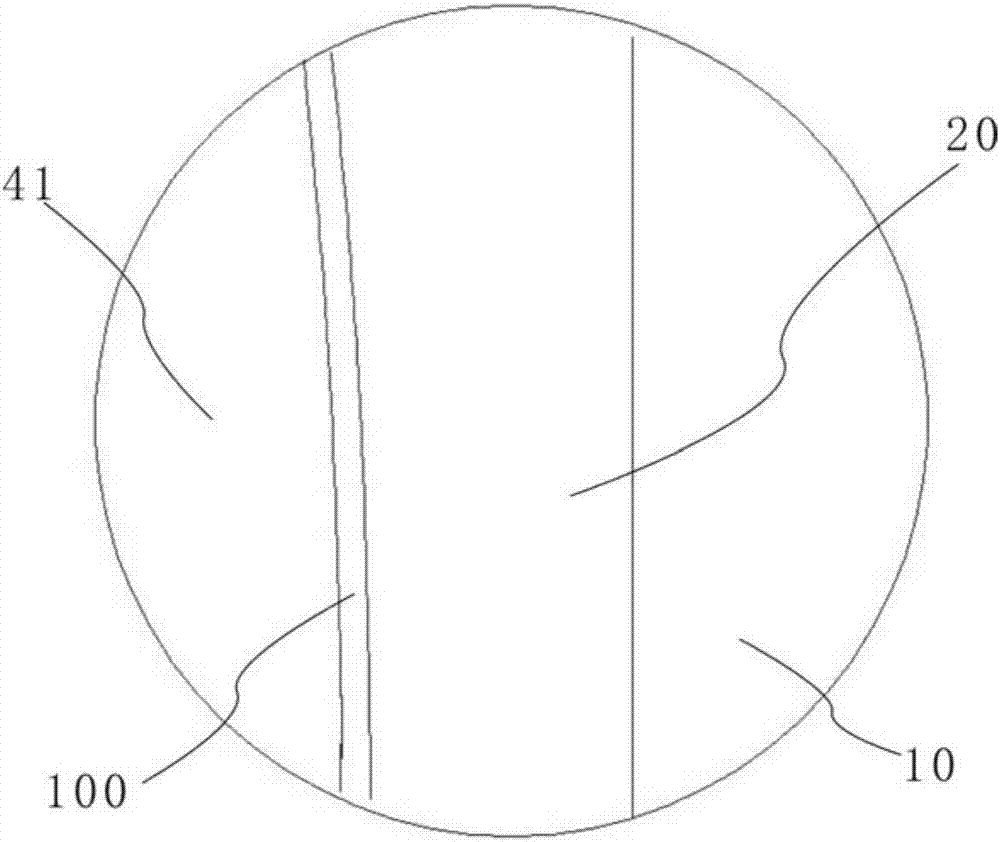

[0027] As shown in the figure, this embodiment provides a steel-aluminum composite mold for high water boots, including a composite upper mold, a steel lower mold 30, an aluminum inner core 40 and a steel flower plate 50, and the composite upper mold is composed of The aluminum backing plate 10 and the steel formwork 20 are composed, and the aluminum backing plate 10 and the steel formwork 20 are fastened together by bolts. Preferably, the steel lower mold 30, the steel formwork 20 and the steel flower plate 50 are all made of No. 45 steel material by milling machine and CNC, and the aluminum backing plate 10 is made of national standard aluminum material by milling machine and CNC. , the aluminum inner core 40 is made of imported 7075 aluminum material and processed by milling machine and CNC.

[0028] In this embodiment, the composite upper mold is provided with an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com