A kind of method that uses na2co3 to assist in synthesizing low-silicon-aluminum ratio x-type molecular sieves

A low-silicon-aluminum ratio, molecular sieve technology, applied in crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of small variation range of water-base ratio, large preparation difficulty, and narrow molecular sieve formula synthesis range. , to broaden the synthesis range, reduce the difficulty of production, and achieve the effect of fine modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

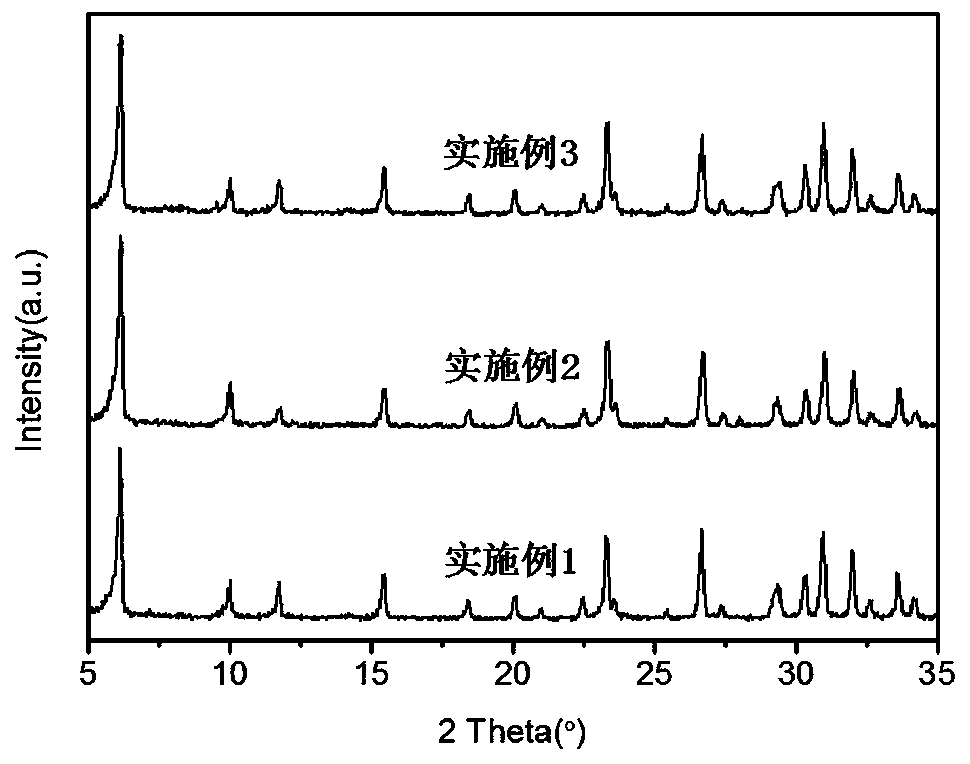

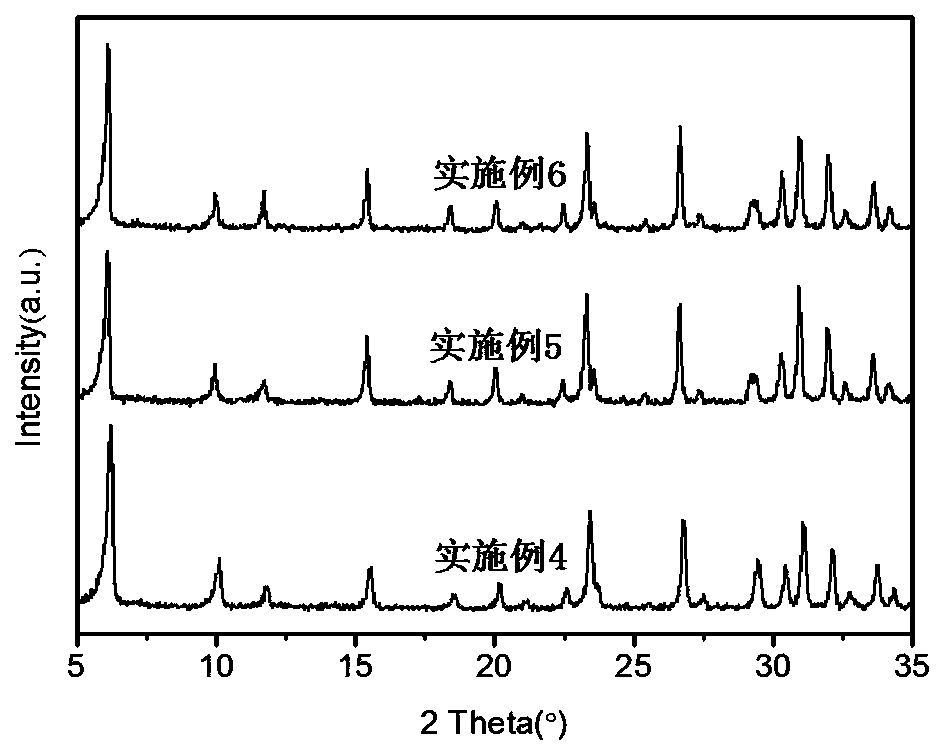

Examples

Embodiment 1

[0030] One uses Na 2 CO 3 The method for assisting in the synthesis of X-type molecular sieves with a low silicon-aluminum ratio specifically comprises the following steps:

[0031] (1) Preparation of directing agent

[0032] 1.382g sodium aluminate solid (Al 2 o 3 0.0056mol, Na 2 (0.0078mol), 6.396g sodium hydroxide (0.0768mol) were added in 18.6ml deionized water to obtain a high alkalinity sodium aluminate solution, and then 6.4ml sodium silicate solution (SiO 2 0.032mol, Na 2 O 0.01mol) was slowly added into the high alkalinity sodium aluminate solution, stirred at room temperature for 0.5h, and aged at 25°C for 9h to become the directing agent. Na 2 O:SiO 2 :Al 2 o 3 :H 2 O=0.0946:0.032:0.0056:1.3889=17:5.76:1:250, wherein the calculation of the amount of water is: (6.4+18.6) / 18=1.3889mol.

[0033] (2) Use Na 2 CO 3 Auxiliary Synthesis of Raw Powder of X-type Molecular Sieve with Low Si-Al Ratio

[0034] 2.488g sodium aluminate (Al 2 o 3 0.0100mol, Na ...

Embodiment 2

[0037] One uses Na 2 CO 3 The method for synthesizing low-silicon-aluminum ratio X-type molecular sieves specifically comprises the following steps:

[0038] (1) Preparation of directing agent

[0039] Under stirring conditions, add 1.382g sodium aluminate solid and 6.396g sodium hydroxide to 18.6ml deionized water in turn to obtain a high alkalinity sodium aluminate solution, then slowly add 6.4ml sodium silicate solution to high alkalinity sodium aluminate In the solution, stir at room temperature for 0.5h, and then stand and age at 25°C for 10h to become the directing agent.

[0040] (2) Use Na 2 CO 3 Auxiliary Synthesis of Raw Powder of X-type Molecular Sieve with Low Si-Al Ratio

[0041] 2.488g sodium aluminate (Al 2 o 3 0.0100mol, Na 2 (0.0140mol), 4.559g anhydrous sodium carbonate (Na 2 CO 3 0.0429mol, Na 2 (0.0429mol), 1.893g solid sodium hydroxide (Na 2 (00.0227mol), 3.099g solid potassium hydroxide (K 2 O 0.0235mol) add 19.8ml deionized water (H 2 O 1...

Embodiment 3

[0044] One uses Na 2 CO 3 The method for synthesizing low-silicon-aluminum ratio X-type molecular sieves specifically comprises the following steps:

[0045] (1) Preparation of directing agent

[0046] Under stirring conditions, add 1.382g sodium aluminate solid and 6.396g sodium hydroxide to 18.6ml deionized water in turn to obtain a high alkalinity sodium aluminate solution, then slowly add 6.4ml sodium silicate solution to high alkalinity sodium aluminate In the solution, stir at room temperature for 0.5h, and then stand and age at 30°C for 8h to become the directing agent.

[0047] (2) Use Na 2 CO 3 Auxiliary Synthesis of Raw Powder of X-type Molecular Sieve with Low Si-Al Ratio

[0048] Under stirring conditions, 2.488g of sodium aluminate, 4.129g of anhydrous sodium carbonate, 1.554g of solid sodium hydroxide, and 3.059g of solid potassium hydroxide were stirred until they were completely dissolved, and then 3.83ml of sodium silicate solution was slowly added. Stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com