A kind of composite latex based on epoxy-modified acrylic resin and preparation method thereof

A technology of acrylic resin and epoxy diacrylate, which is applied in the field of composite latex, can solve the problems of difficult judgment of the reaction end point, difficult control of the preparation process, and easy occurrence of phase-to-phase compatibility between epoxy resin and polyacrylic resin, and achieve Good passivation effect, mild reaction, and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

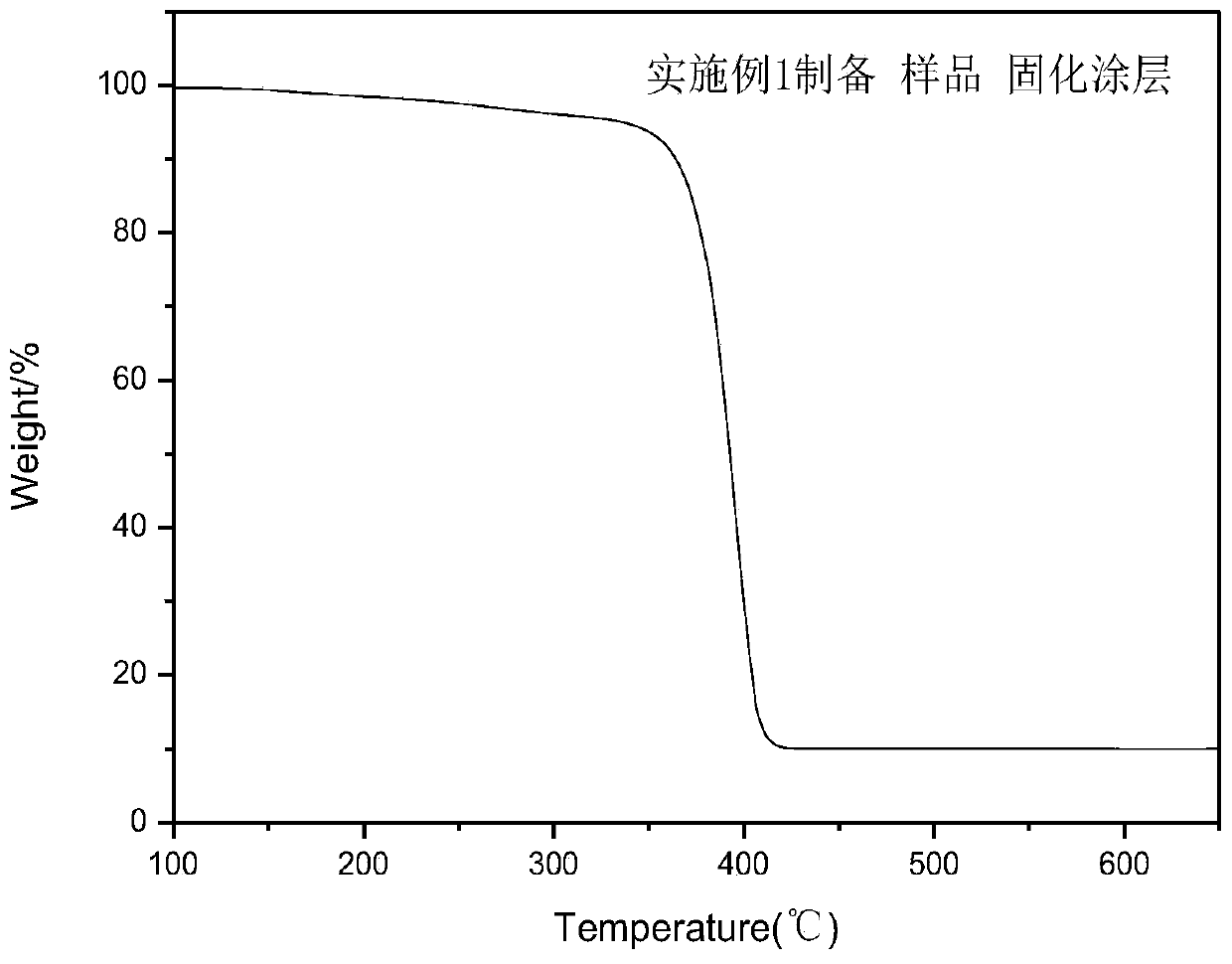

Embodiment 1

[0035] A composite latex based on an epoxy-modified acrylic resin comprising:

[0036] Water, 60wt%;

[0037] Acrylate monomer mixture, 35wt%;

[0038] Bisphenol A epoxy diacrylate 6104Y (China Miki), 1wt%;

[0039] Anionic emulsifier Rhodafac RS-610 (Rhodia), 2.5wt%;

[0040] Nonionic emulsifier ABEX2535 (Rhodia), 1.4wt%;

[0041] Ammonium persulfate, 0.1 wt%.

[0042] Wherein, the acrylate monomer mixture includes the following materials:

[0043] Methyl methacrylate, 50wt%;

[0044] Styrene, 5wt%;

[0045] Isooctyl acrylate, 40wt%;

[0046] Acrylic acid, 2.5wt%;

[0047] Hydroxyethyl methacrylate, 2.5 wt%.

[0048] The composite latex based on epoxy-modified acrylic resin is prepared by the following steps:

[0049] The first step: 70% of the total amount of the initiator is dissolved in water accounting for 30% of the total amount, and then poured into the reaction bottle;

[0050] The second step: mix the bisphenol A epoxy diacrylate with the acrylic monomer mi...

Embodiment 2

[0053] A composite latex based on an epoxy-modified acrylic resin comprising:

[0054] Water, 40wt%;

[0055] Acrylate monomer mixture, 41wt%;

[0056] Bisphenol A epoxy diacrylate 6104Y (China Miki), 10wt%;

[0057] Anionic emulsifier Rhodafac RS-610 (Rhodia), 4wt%;

[0058] Nonionic emulsifier ABEX2535 (Rhodia), 4wt%;

[0059] Ammonium persulfate, 1 wt%.

[0060] Wherein, the acrylate monomer mixture includes the following materials:

[0061] Methyl methacrylate, 60wt%;

[0062] Styrene, 10wt%;

[0063] Isooctyl acrylate, 25wt%;

[0064] Acrylic acid, 0.5wt%;

[0065] Hydroxyethyl methacrylate, 4.5 wt%.

[0066] The composite latex based on epoxy-modified acrylic resin is prepared by the following steps:

[0067] The first step: 40% of the total amount of the initiator is dissolved in water accounting for 50% of the total amount, and then poured into the reaction bottle;

[0068] The second step: mix the bisphenol A epoxy diacrylate with the acrylic monomer mixtur...

Embodiment 3

[0071] A composite latex based on an epoxy-modified acrylic resin comprising:

[0072] Water, 30wt%;

[0073] Acrylate monomer mixture, 60wt%;

[0074] Bisphenol A epoxy diacrylate 6104Y (China Miki), 4wt%;

[0075] Anionic emulsifier Rhodafac RS-610 (Rhodia), 2.8wt%;

[0076] Nonionic emulsifier ABEX2535 (Rhodia), 2.8wt%;

[0077] Ammonium persulfate, 0.4 wt%.

[0078] Wherein, the acrylate monomer mixture includes the following materials:

[0079] Methyl methacrylate, 55% by weight;

[0080] Styrene, 8wt%;

[0081] Isooctyl acrylate, 31.5wt%;

[0082] Acrylic acid, 5wt%;

[0083] Hydroxyethyl methacrylate, 0.5 wt%.

[0084] The composite latex based on epoxy-modified acrylic resin is prepared by the following steps:

[0085] The first step: 50% of the total amount of the initiator is dissolved in water accounting for 45% of the total amount, and then poured into the reaction bottle;

[0086] The second step: mix the bisphenol A epoxy diacrylate with the acrylic mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap