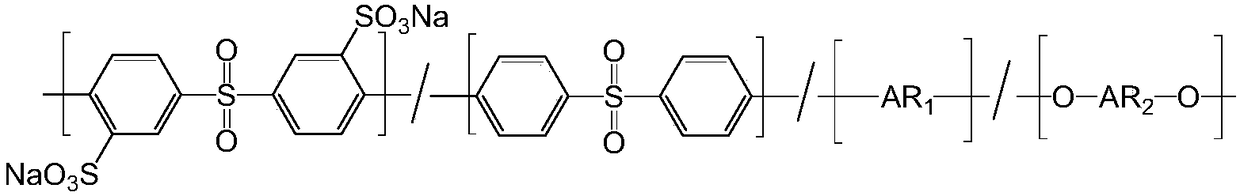

Sulfonated polyaryl ether sulfone copolymer containing pyridine group, preparation method and application

A technology for sulfonating polyarylethersulfone and pyridine groups, which is used in electrochemical generators, fuel cells, electrical components, etc., can solve the problem that the water content of proton conductivity cannot meet the requirements of use, mechanical properties decline, and service life is reduced. problem, to achieve the effect of good application prospects, high antioxidant stability, and low methanol permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

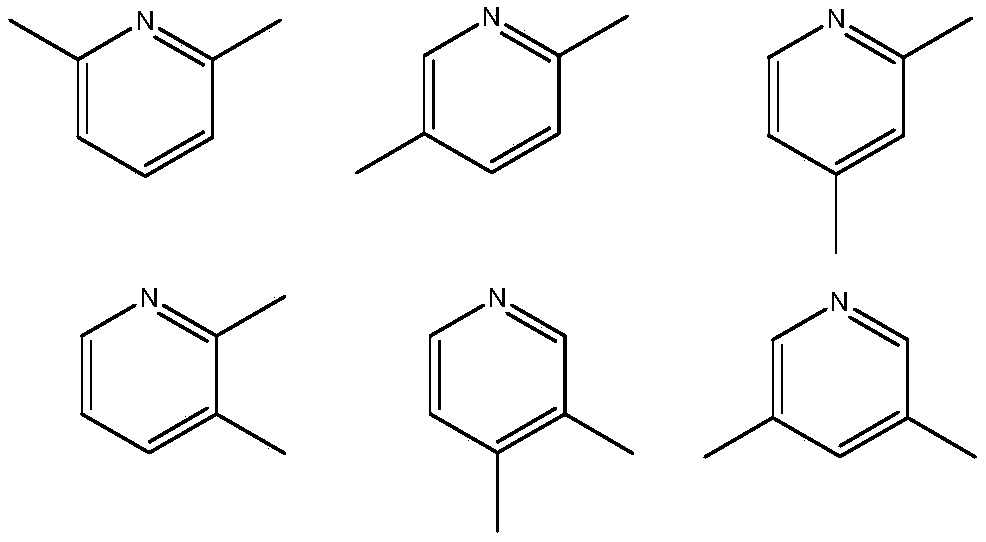

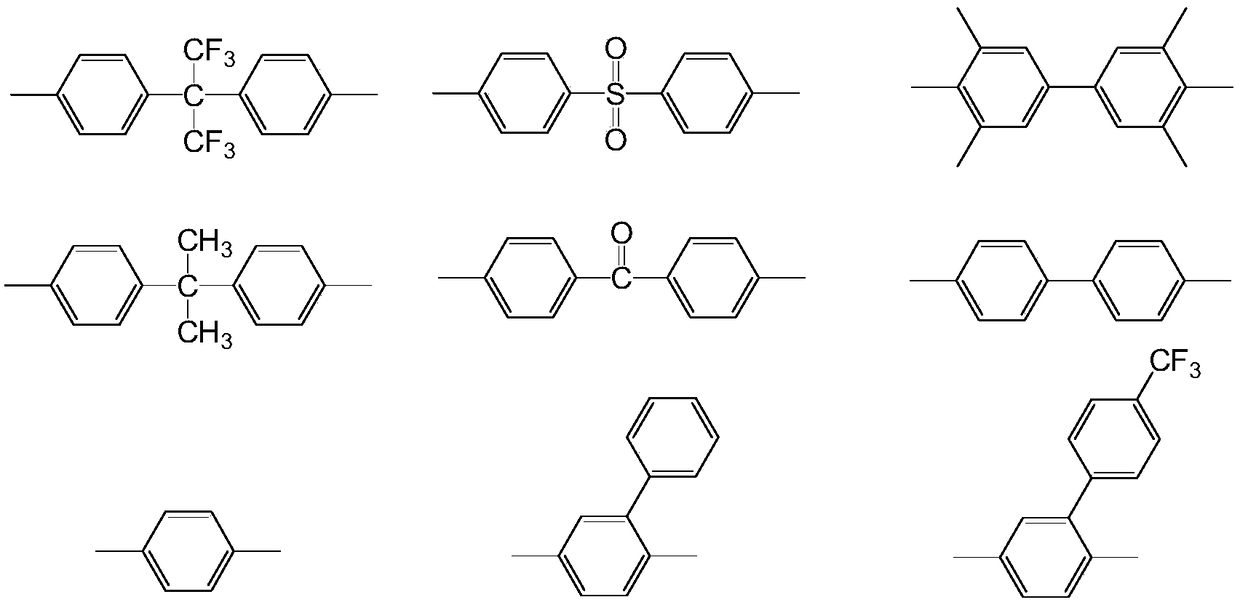

[0023] Add 0.1mol bisphenol A, 0.02mol 2,3-dichloropyridine, 0.03mol 4,4'-dichlorobis Phenylsulfone, 0.05mol 3,3'-sodium disulfonate-4,4'-dichlorodiphenylsulfone, with 1.05mol potassium carbonate as salt-forming agent, dimethylformamide as solvent, and toluene as water water-carrying agent at 120°C for 3 hours, then evaporate the water-carrying agent, then raise the temperature to 140°C to continue the reaction for 20 hours; after the reaction is complete, pour the mixture into distilled water to obtain a light yellow strip solid, which is crushed into fine powder and used Washing with acetone for 3 times, and then washing with distilled water for 3 times; finally drying at 60°C to obtain a sulfonated polyarylethersulfone copolymer containing pyridine groups with a sulfonation degree of 1.0.

Embodiment 2

[0025] Add 0.1mol hexafluorobisphenol A, 0.03mol 2,4-dichloropyridine, 0.03mol 4,4'-di Chlorodiphenylsulfone, 0.04mol 3,3'-sodium disulfonate-4,4'-dichlorodiphenylsulfone, with 1.1mol sodium carbonate as salt-forming agent, dimethylacetamide as solvent, xylene It is a water-carrying agent; carry water at 120°C for 4 hours, then steam the water-carrying agent, and then raise the temperature to 150°C to continue the reaction for 16 hours; after the reaction is complete, pour the mixture into acetone to obtain a light yellow strip solid, which is crushed into fine After powdering, it was washed 5 times with acetone, and then 5 times with distilled water; finally, it was dried at 80°C to obtain a sulfonated polyaryl ether sulfone copolymer containing pyridine groups with a sulfonation degree of 0.8.

Embodiment 3

[0027] Add 0.1mol hydroquinone, 0.01mol 2,5-dichloropyridine, 0.02mol 4,4'-dichloropyridine to a three-necked flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection Diphenylsulfone, 0.06mol 3,3'-sodium disulfonate-4,4'-dichlorodiphenylsulfone, with 1.2mol potassium carbonate as salt-forming agent, N-methylpyrrolidone as solvent, toluene as band Aqueous agent: add water at 130°C for 5 hours, then steam the agent with water, then raise the temperature to 170°C and continue to react for 14 hours; after the reaction is complete, pour the mixture into distilled water to obtain a light yellow strip solid, which can be crushed into fine powder Washing with acetone for 4 times and distilled water for 4 times; finally drying at 70°C to obtain a sulfonated polyaryl ether sulfone copolymer containing pyridine groups with a sulfonation degree of 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com