High Density Tungsten Alloy Moisture and Heat Resistant Anticorrosion Coating

A high-density tungsten alloy and anti-corrosion coating technology, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, polyurea/polyurethane coatings, etc., can solve problems such as corrosion, low anti-corrosion performance, and cannot meet the protection requirements of tungsten alloys for moisture and heat resistance. Effect of permeation diffusion and good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

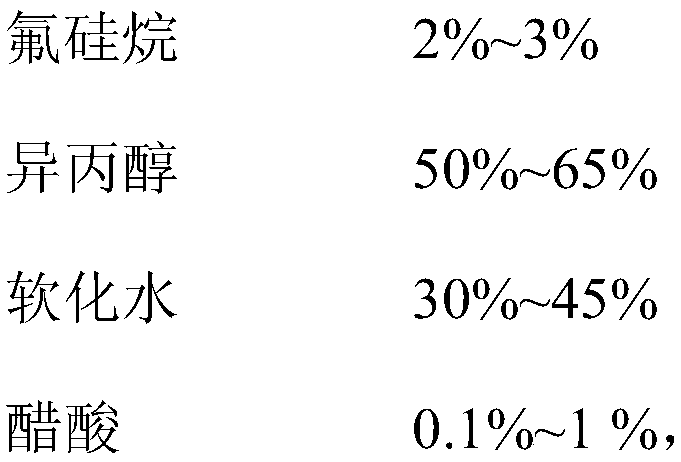

[0042] (1) Preparation of high-density tungsten alloy heat and humidity resistant anti-corrosion primer: Add 50kg of isopropanol and 32kg of demineralized water into the reaction kettle, add 0.4kg of acetic acid, and the pH value is about 5 after testing. Raise the temperature to 55°C±2°C, slowly add 2kg of heptadecylfluorodecyltriethoxysilane under stirring for 1 hour, and keep it at this temperature for 8 hours after the addition is completed, to prepare a high-density tungsten alloy resistant to heat and humidity Primer.

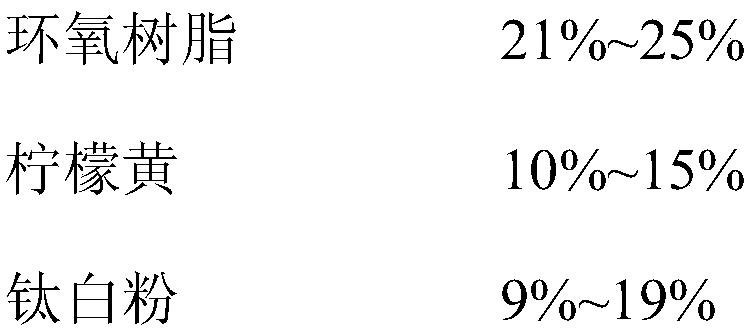

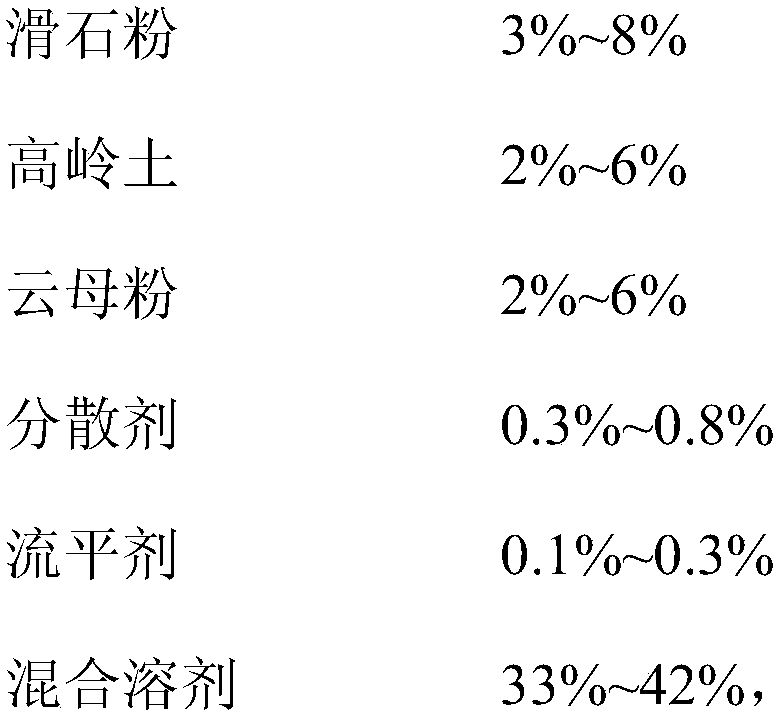

[0043] (2) Preparation of component A of high-density tungsten alloy heat and humidity resistant anti-corrosion finish: add 20kg of cyclohexanone and 5kg of methyl ethyl ketone into the reaction kettle, heat up to reflux state, add 25kg of epoxy resin 607 in three times, and reflux The state was kept warm for 2 hours to obtain an epoxy resin solution. Add 0.5kg of dispersant BYK-110, 0.15kg of leveling agent BYK-320, 8kg of cyclohexanone, 8kg of methyl e...

Embodiment 2

[0047] (1) Preparation of high-density tungsten alloy heat and humidity resistant anti-corrosion primer: Add 50kg of isopropanol and 40kg of demineralized water into the reaction kettle, add 0.45kg of acetic acid, and the pH value is about 5 after testing. Raise the temperature to 55°C±2°C, slowly add 2.5kg of heptadecylfluorodecyltriethoxysilane under stirring, and take 1 hour to slowly add 2.5kg of heptadecafluorodecyltriethoxysilane. After the addition is completed, keep it at this temperature for 8 hours to prepare a high-density tungsten alloy resistant to heat and humidity. Anti-corrosion primer.

[0048](2) Preparation of component A of high-density tungsten alloy heat and humidity resistant anti-corrosion finish paint: add 23kg of cyclohexanone and 2kg of butanone into the reaction kettle, heat up to reflux state, add 20kg of epoxy resin 607, 5kg in three times Epoxy resin 609 was prepared in a reflux state for 2 hours to obtain an epoxy resin solution. Add 0.4kg of d...

Embodiment 3

[0052] (1) Preparation of high-density tungsten alloy heat and humidity resistant anti-corrosion primer: Add 60kg of isopropanol and 36kg of demineralized water into the reaction kettle, add 0.5kg of acetic acid, and the pH value is about 5 after testing. Raise the temperature to 55°C±2°C, slowly add 2kg of tridecafluorooctyltriethoxysilane under stirring, and take 1 hour to slowly add 2kg of tridecafluorooctyltriethoxysilane. After the addition is completed, keep it at this temperature for 8 hours to prepare a high-density tungsten alloy resistant to heat and humidity. Primer.

[0053] (2) Preparation of component A of high-density tungsten alloy heat and humidity resistant anti-corrosion finish paint: add 20kg of cyclohexanone and 5kg of methyl ethyl ketone into the reaction kettle, heat up to reflux state, add 25kg of epoxy resin 609 in three times, and reflux The state was kept warm for 2 hours to obtain an epoxy resin solution. Add 0.6kg of dispersant BYK-110, 0.2kg of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com