Regenerator in catalytic cracking device

A catalytic cracking device and regenerator technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problem that ammonia and other compounds cannot be effectively processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

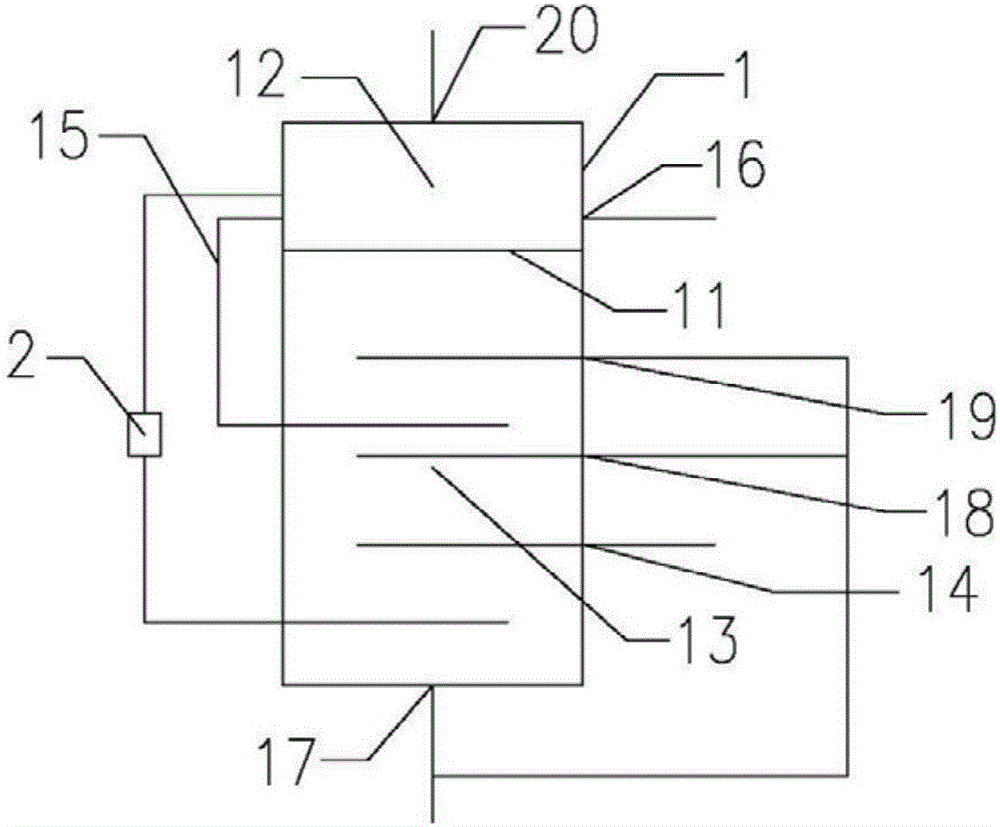

[0025] A regenerator in a catalytic cracking unit, the regenerator 1 includes a large hole distribution plate 11, a catalyst inlet 14, a catalyst circulation pipeline 15, a regenerated catalyst outlet 16, a main air pipeline I17, a main air pipeline II18, a main air Pipeline III19, flue gas outlet 20;

[0026] The large hole distribution plate 11 in the regenerator 1 divides the regenerator 1 into an upper two-dense bed 12 and a lower charred pot 13, and the inlet 14 of the catalyst to be produced is arranged on the side of the charred pot 13, and the The main air pipeline I17 is arranged at the bottom of the coking tank 13, the main air pipeline II18 and the main air pipeline III19 are arranged on the side of the coking tank 13, the inlet of the catalyst circulation pipeline 15 and the inlet of the external heat collector 2 are arranged On the side of the double-dense bed 12, the outlet of the catalyst circulation line 15 and the outlet of the external heat collector 2 are ar...

Embodiment 2

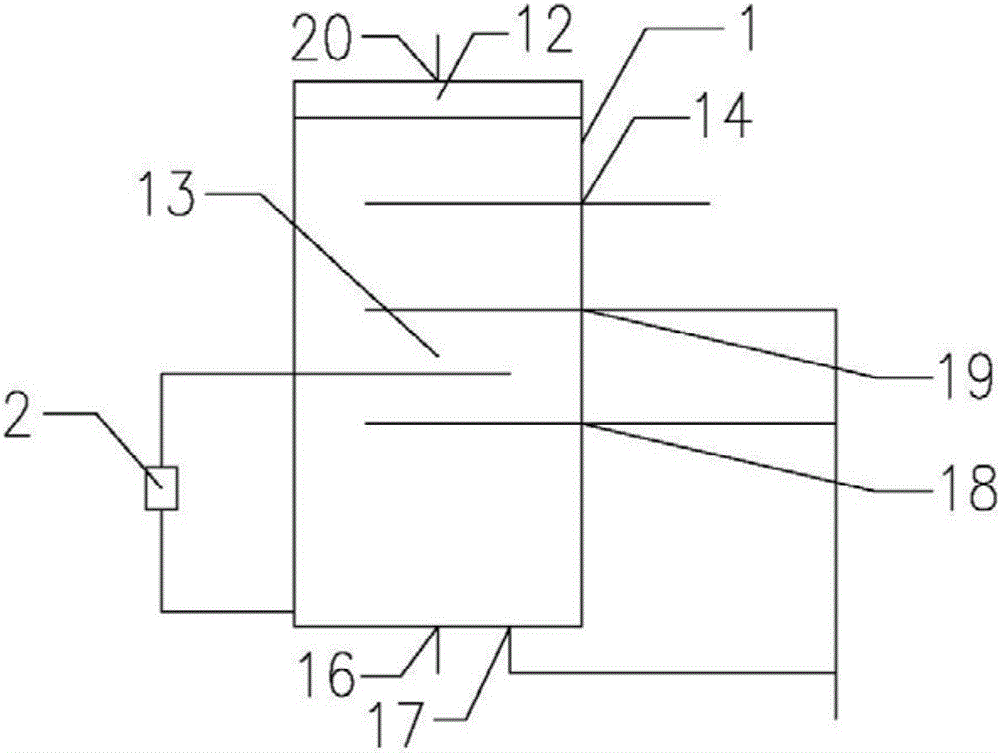

[0035] A regenerator in a catalytic cracking unit, the regenerator 1 includes a standby catalyst inlet 14, a regenerated catalyst outlet 16, a main air pipeline I17, a main air pipeline II18, a main air pipeline III19, and a flue gas outlet 20;

[0036] The upper part of the regenerator 1 is a dilute-phase space 12, and the lower part is a dense-phase catalyst bed 13. The inlet 14 of the standby catalyst is arranged on the side of the dense-phase catalyst bed 13, and the main air line I17 is arranged on the dense-phase catalyst bed. 13, the main air pipeline II18 and the main air pipeline III19 are arranged on the side of the catalyst dense-phase bed 13, and the inlet of the external heat extractor 2 and the outlet of the external heat extractor 2 are arranged on the side of the catalyst dense-phase bed 13. Side, the distance from the standby catalyst inlet 14 to the bottom of the catalyst dense-phase bed 13>the distance from the main air line III19 to the bottom of the catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com