Method for testing oil oxidation stability

A technology of oxidation stability and test method, which is applied in the direction of material inspection products, etc., can solve the problems of inability to continuously sample, the cleaning and dispersibility has not been tested, and the test method of oil oxidation stability is inconvenient, so as to achieve the effect of comprehensive testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

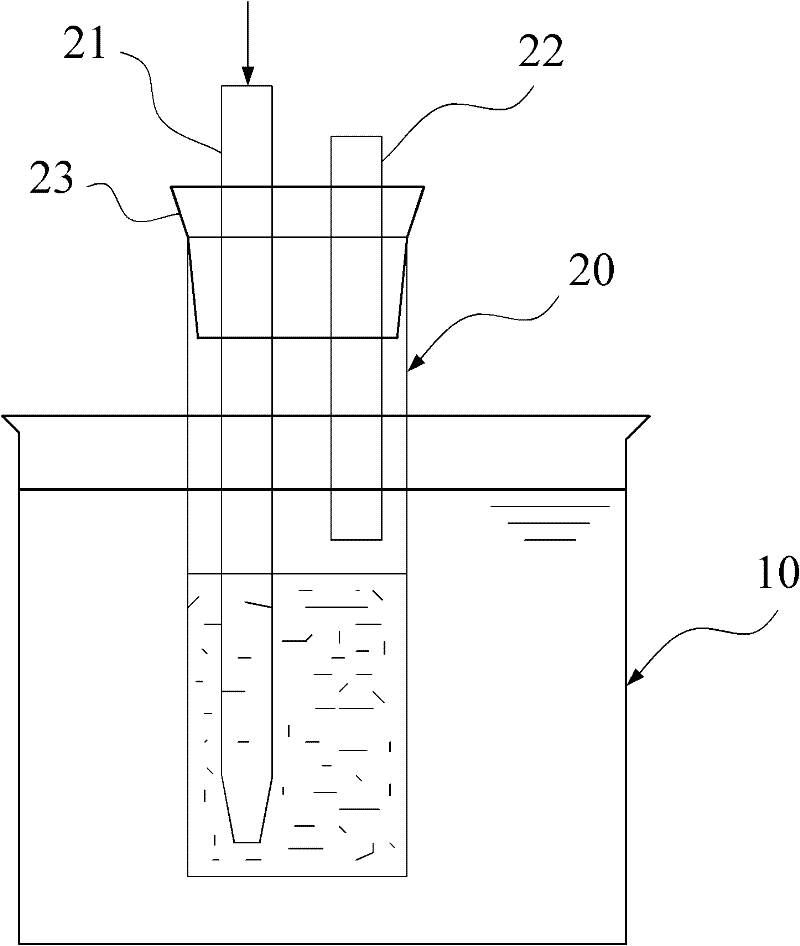

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, evaluate oil performance:

[0017] 1. Comparing the oxidation resistance and detergency and dispersibility of commercially available oil A and commercially available oil B

[0018] In order to compare the use of oil A and oil B with similar performance, the above method is adopted, and the test conditions are set as follows. The test temperature is 150°C, the air flow rate is 10L / h, 2.5g iron wire is added as a catalyst, and samples are taken and analyzed every 12 hours.

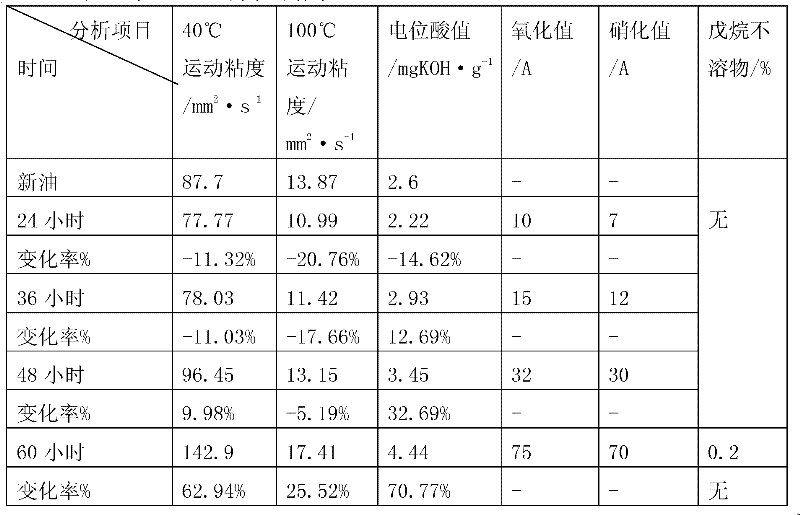

[0019] The test result of table 1 oil product A

[0020]

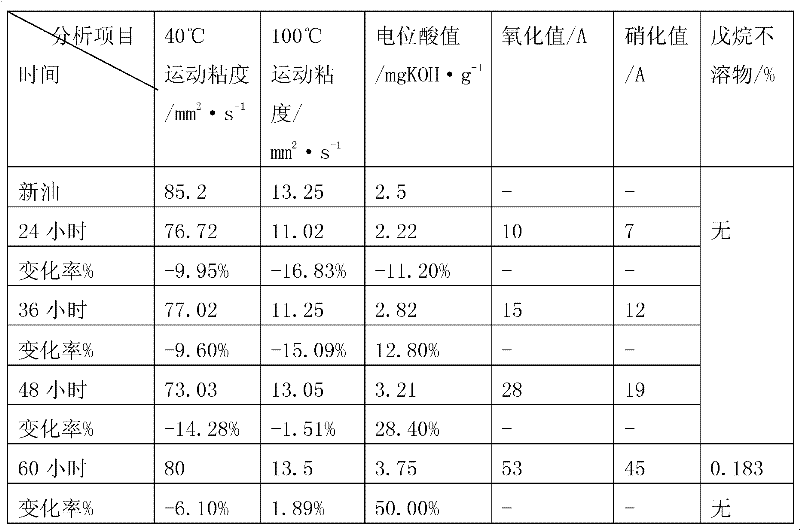

[0021] Table 2 Test results of oil product B

[0022]

[0023] It can be seen from the above test that before 48 hours, the test results of the two oil products are similar. Beginning at 48 hours, the performance of the two oils showed a difference. The anti-oxidation performance of sample B is better than that of sample A. After 60 hours, the test is completed, and the cleaning and dispersibility of sample B is also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com