TL immobilization enzyme and application thereof

A technology for immobilizing lipase and lipase, which is applied to the immobilized enzyme method and its application field, and can solve the problems of not producing soap, unable to meet production requirements, producing soap and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0092] An exemplary preferred embodiment of the present invention is as follows:

[0093] Step 1. Carrier processing

[0094] Soak the macroporous adsorption resin carrier in deionized water to remove impurities, then soak in ethanol overnight to remove organic impurities and other insoluble matter, rinse with deionized water until there is no alcohol smell, and then soak in deionized water for storage.

[0095] Alternatively, wash the ion exchange resin with deionized water, alternately treat it with 5% NaOH and 5% HCl for 2 to 5 times, and then treat it with 5% NaOH for about two hours each time, and then treat it with deionized water until it reaches water level. Neutral, soak in deionized water for later use.

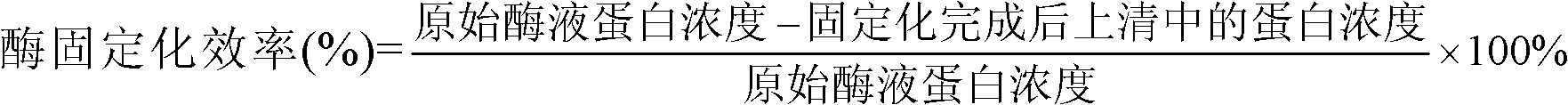

[0096] Step 2. Enzyme immobilization

[0097] Weigh 40g of the treated resin carrier into a 250ml Erlenmeyer flask, put 40ml of TL enzyme solution into it, and fix it in a water-bath shaker at 25°C at 150rpm. During this period, take the supernatant at regular int...

Embodiment 1

[0112] Embodiment 1. Adopt macroporous adsorption resin to prepare immobilized enzyme

[0113] The macroporous adsorption resins D101, HPD100A or X-5 (D101 and HPD100A were purchased from Hebei Cangzhou Baoen Chemical Co., Ltd., and X-5 was purchased from Shanghai Huazhen Resin Co., Ltd.) were soaked in deionized water for about 12 hours to remove impurities, Then soak in 95% ethanol overnight to remove organic impurities and other insoluble matter, rinse with deionized water until there is no alcohol smell, and place in deionized water for later use.

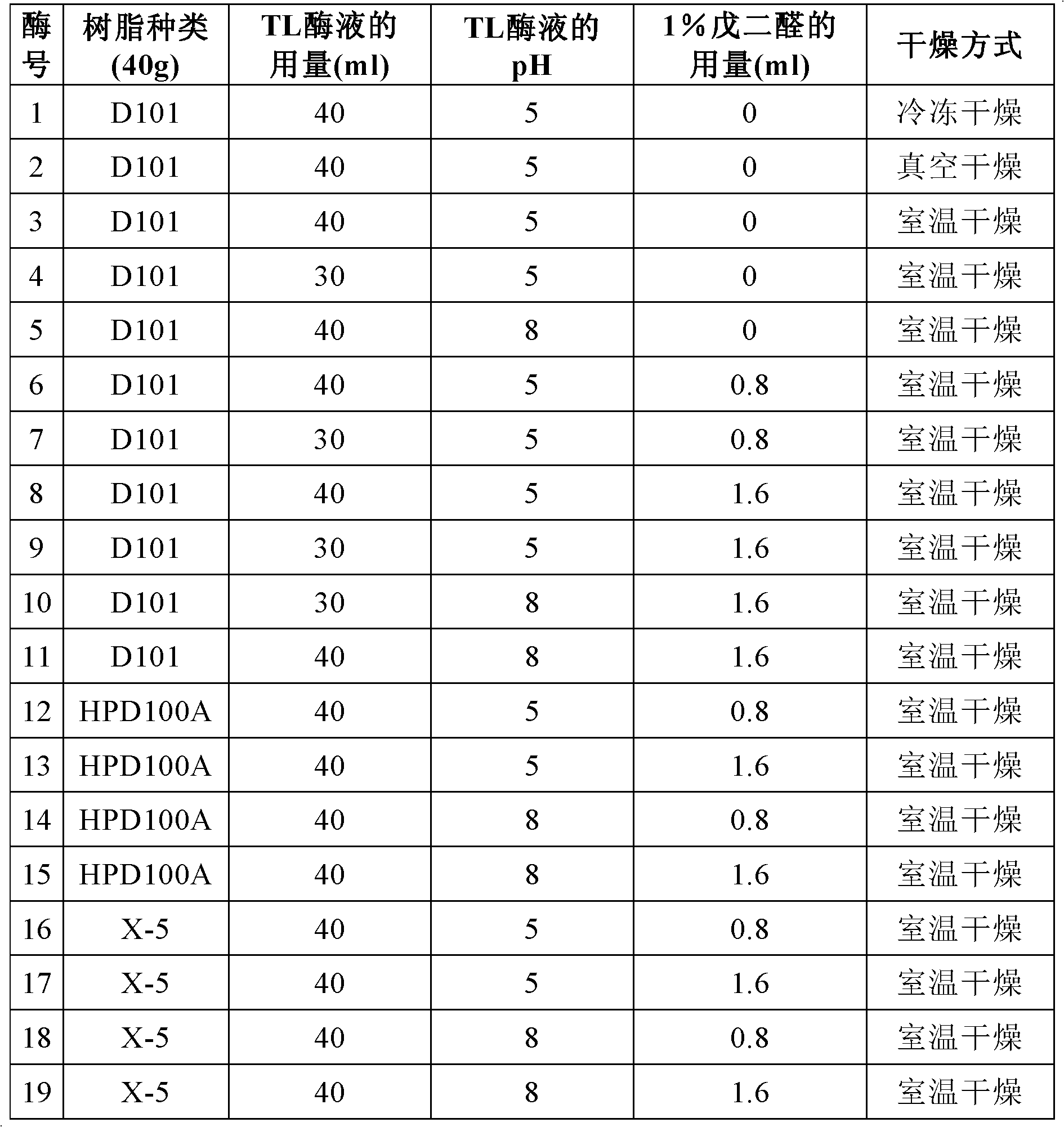

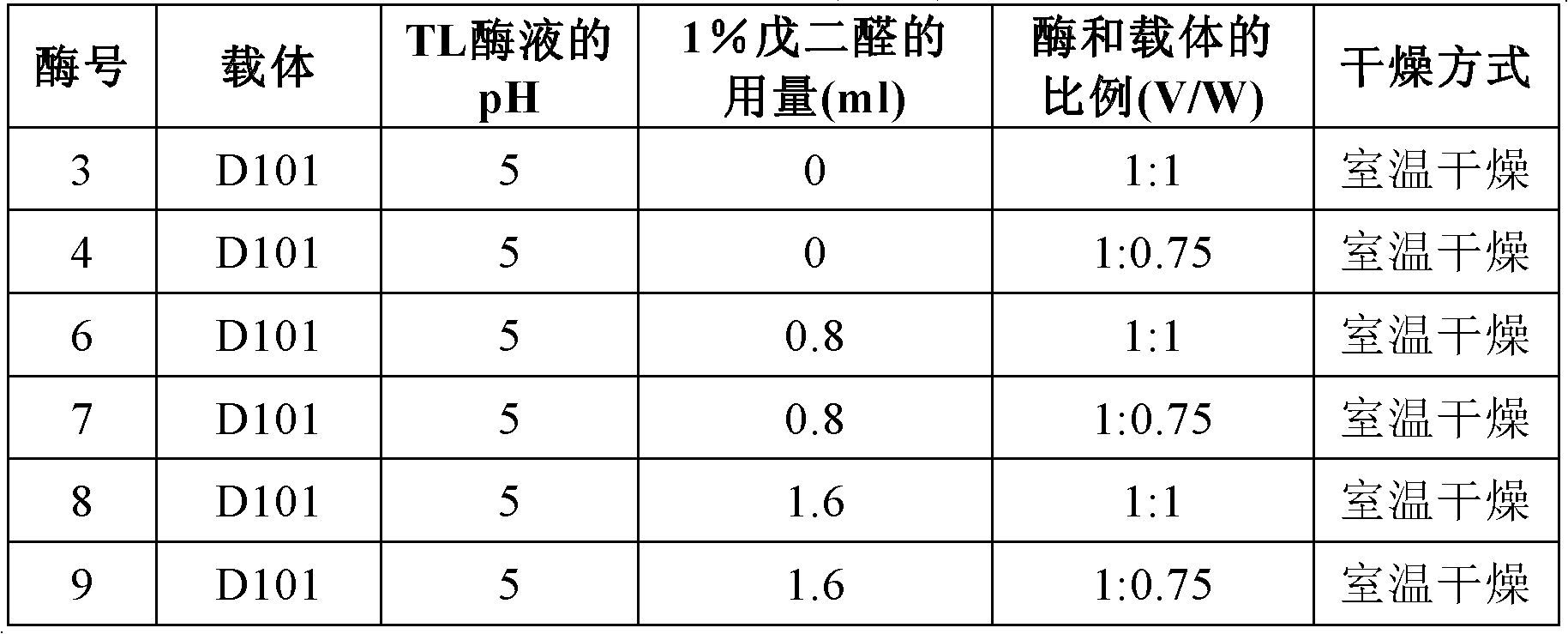

[0114] Prepare immobilized enzyme 1-19 according to the following formula and steps:

[0115] 1. Weigh 40g of the processed D101 resin into a 250ml Erlenmeyer flask, add 40ml pH5 TL enzyme solution, shake at 150rpm in a shaker at 25°C for 2h, then take out the resin and put it into a dry petri dish, and put it into a freeze-dried Drying is carried out in the machine, and the specific freeze-drying parameters are set as:

[01...

Embodiment 2

[0149] Embodiment 2. adopt ion exchange resin to prepare immobilized enzyme

[0150] Styrene-DVB201 × 2 resin (purchased from Tianjin Nankai Hecheng Technology Co., Ltd.) was first washed with deionized water, then alternately soaked twice with 5% NaOH and 5% HCl, and then soaked once with 5% NaOH. The second treatment is about two hours, and then washed with deionized water until the water is neutral, soaked in deionized water for later use.

[0151] Prepare immobilized enzyme 20-24 according to the following formula and steps:

[0152] 1. Take out 40g of the treated Styrene-DVB201×2 resin into a 250ml Erlenmeyer flask, add 40ml of pH5 TL enzyme solution, and 0.8ml of 1% glutaraldehyde solution, shake at 150rpm for 2h in a shaker at 25°C, and then take out the resin Put it into a dry petri dish, put it in a well-ventilated place for natural air-drying, and obtain immobilized enzyme 20 after drying.

[0153] 2. Take out 40g of the processed Styrene-DVB201×2 resin into a 250m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com