Tea oil processing method and device special for tea oil processing method

A processing method and technology of special equipment, applied in the fields of application, edible oil/fat, fat oil/fat production, etc., can solve the problems of difficulty in guaranteeing the quality of camellia oil, loss of nutritional components of camellia oil, long heating time of camellia oil, etc. Less, good health care effect, no chemical solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

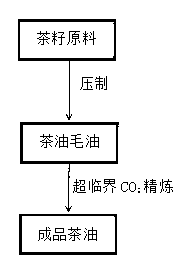

[0032] (1) Raw material pretreatment: take the tea seeds and dry them at a low temperature at 60°C until the moisture of the tea seeds is 5%, and then remove the shells;

[0033] (2) Cold-press the processed tea seeds, and the oil output temperature is 60°C to obtain crude tea oil, which is filtered;

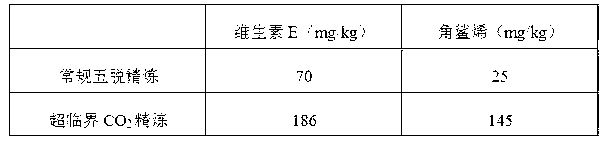

[0034] (3) Supercritical CO 2 Refining: The crude tea oil is continuously fed into the refining column to control the speed of entering the oil and enter the supercritical CO in the refining column 2 When the fluid is contacted at 40℃ and 18MPa, the impurities in the crude oil, such as free fatty acids and odor substances, are dissolved in supercritical CO 2 Fluid, then supercritical CO 2 The fluid enters the analysis kettle, the pressure is reduced to 8MPa, and the impurities are precipitated and discharged from the discharge port; CO 2 After being condensed by the condenser, it enters CO 2 The storage tank is used for recycling. The impurities in the crude tea oil are removed to obt...

Embodiment 2

[0038] (1) Raw material pretreatment: take the tea seeds and dry them at a low temperature at 60°C until the moisture content of the tea seeds is 6%, and then remove the shells;

[0039] (2) Cold-squeeze the treated tea seeds, the oil output temperature is 50℃, to obtain the crude tea oil, and filter;

[0040] (3) Supercritical CO 2 Refining: The crude tea oil is sent into the refining column, and into the supercritical CO in the refining column 2 When the fluid is in contact at 55℃ and 20MPa, the impurities in the crude oil, such as free fatty acids and odor substances, are dissolved in supercritical CO 2 Fluid, then supercritical CO 2 The fluid enters the analysis kettle, the pressure is reduced to 9MPa, and the impurities are precipitated and discharged from the discharge port; CO 2 After being condensed by the condenser, it enters CO 2 The storage tank is used for recycling. The impurities in the crude tea oil are removed to obtain the finished tea oil.

[0041]

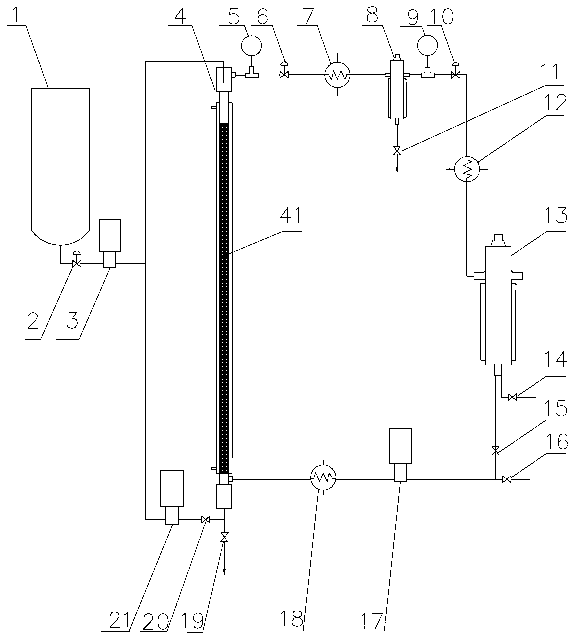

[0042] As shown...

Embodiment 3

[0044] (1) Raw material pretreatment: take the tea seeds and dry them at a low temperature at 50°C until the moisture of the tea seeds is 8%, and then remove the shells;

[0045] (2) Cold-press the processed tea seeds, and the oil output temperature is 40°C to obtain crude tea oil, which is filtered;

[0046] (3) Supercritical CO 2 Refining: The crude tea oil is sent into the refining column, and into the supercritical CO in the refining column 2 When the fluid is contacted at 45℃ and 16MPa, the impurities in the crude oil, such as free fatty acids and odor substances, are dissolved in supercritical CO 2 Fluid, then supercritical CO 2 The fluid enters the analysis kettle, the pressure is reduced to 8.5MPa, and the impurities are precipitated and discharged from the discharge port; CO 2 After being condensed by the condenser, it enters CO 2 The storage tank is used for recycling. The impurities in the crude tea oil are removed to obtain the finished tea oil.

[0047]

[0048] As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com