Laser repair method for hub tenon tooth of heavy-duty gas turbine

A technology of laser repair, hub and tenon teeth, applied in combustion methods, combustion chambers, combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

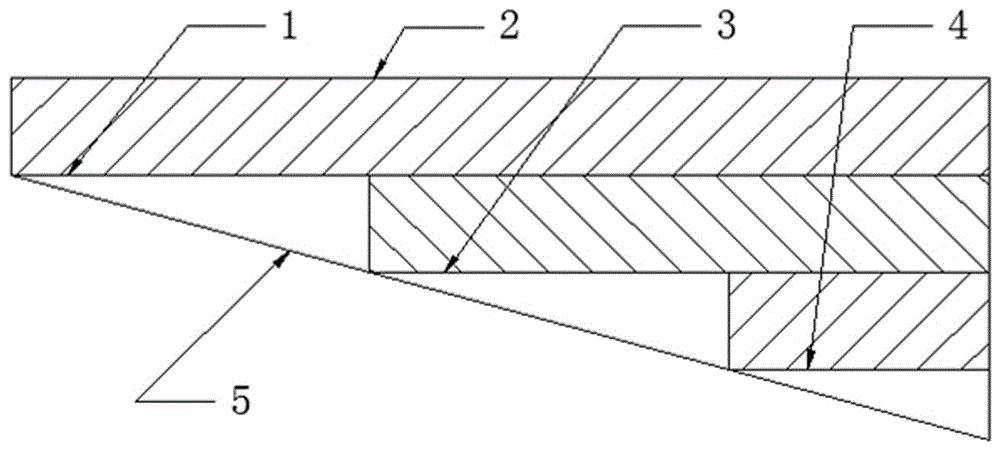

Image

Examples

Embodiment 1

[0050] The No. 1 gas turbine unit of a gas turbine power plant had a major accident in which the rotor blades were broken and the hub was scrapped due to the large wear of the tenon teeth of the hub and the rotor blades, causing economic losses of more than 50 million yuan to the factory. In the same year, Unit 4 also found the same problem as Unit 1. The factory consulted the original manufacturer, and the reply was that the wheel hub could not be repaired and had to be scrapped and replaced. The cost of replacing the new wheel hub was 30 million yuan, and the manufacturing period was 6 months.

[0051] The wheel hub of No. 4 machine can no longer be used normally, and the wheel hub must be replaced with a new one or repaired. Finally, it was decided to use laser cladding technology to remanufacture the wheel hub of No. 4 machine. Its characteristics and technological process mainly include the following steps.

[0052] 1 damage detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com