Calibration method and cross-section determination method of multi-point common beam rutting detection device

A calibration method and rutting technology, applied in roads, buildings, road repairs, etc., can solve problems such as large calibration errors, achieve the effect of improving precision and accuracy, and eliminating calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

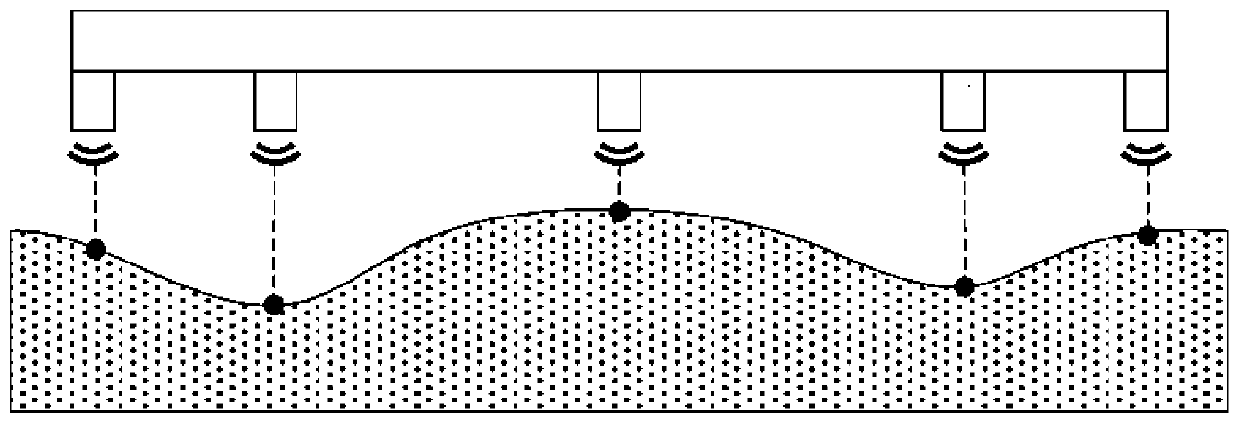

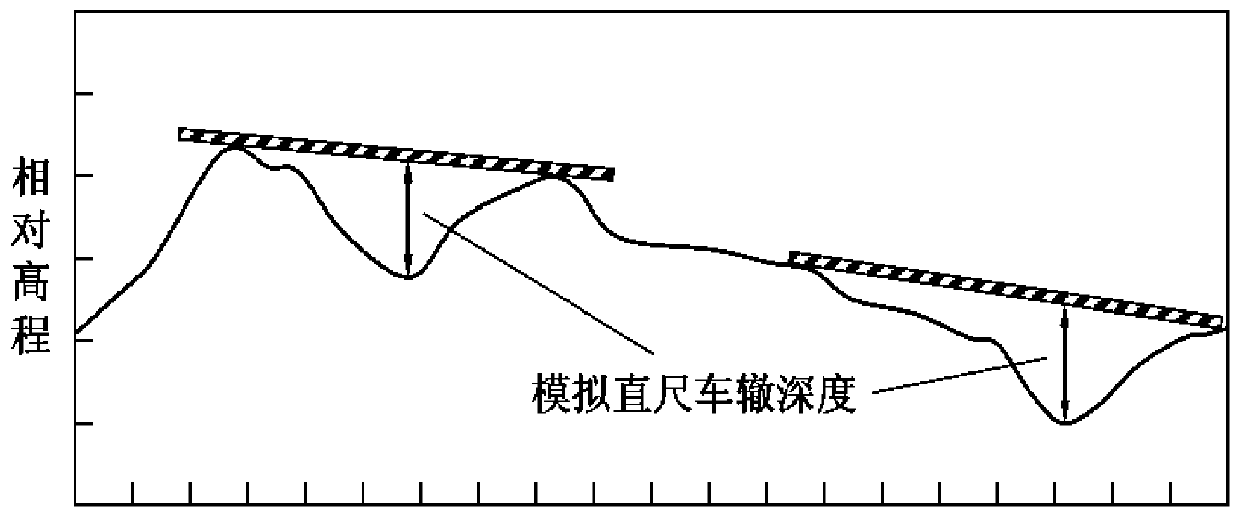

Method used

Image

Examples

Embodiment Construction

[0035] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0036] The calibration process in the embodiment of the present invention includes:

[0037] S11: Among the m lasers on the rut beam, determine the installation angle α of each laser i and the transverse coordinate a i ; Wherein, the horizontal coordinate a i is the lateral coordinate value of the i-th laser relative to the reference laser, the reference laser is a laser located in the middle of the rut beam, and i=1~m;

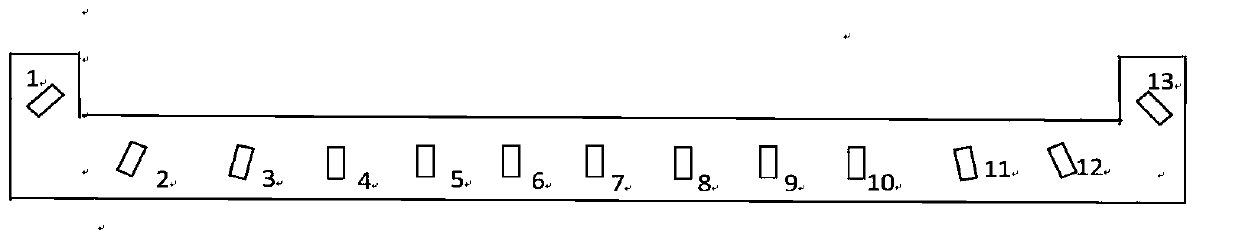

[0038] For details, see Figure 4 , there is a rut detection device with m=13 lasers, and the design installation parameters of each laser on the rut beam (α i ,ai,BAi);

[0039] where α i is the laser installation angle numbered i, clockwise is a positive value, and counterclockwise is a negative value; ai is the horizontal coordinate value of the i-th la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com