Underground precise laboratory efficient vibration isolation method

A laboratory and sophisticated technology, applied in protection devices, buildings, infrastructure engineering, etc., can solve problems such as increased cost, hidden safety hazards, disturbances, etc., and achieve the effect of optimizing vibration isolation performance, ease of construction, and efficient vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

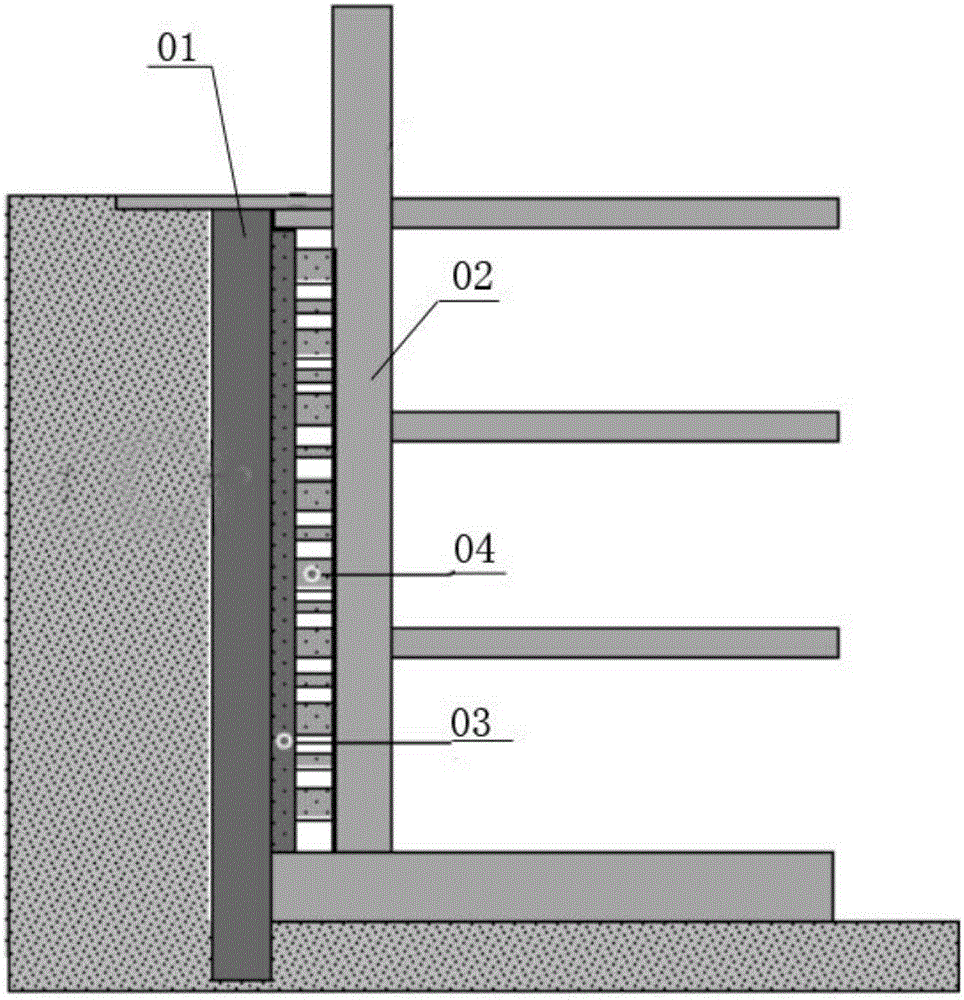

[0011] refer to figure 1 , the present invention provides a high-efficiency vibration isolation method for an underground precision laboratory, which includes: building a retaining wall 01 outside the outer wall 02 of the underground precision laboratory;

[0012] By building retaining walls and improving the filling and contact methods between the basement exterior wall and the surrounding soil, the disturbance of external vibration to the precision laboratory is reduced, and the impact of external environmental vibration on the precision laboratory is greatly weakened from the transmission path.

[0013] Specifically, first carry out the scheme design of the retaining wall, and those skilled in the art can determine the influencing factors of the design scheme of the retaining wall according to the existing techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com