An inspection well installation and construction technology

A construction technique and inspection well technology, applied in water supply devices, waterway systems, buildings, etc., can solve problems such as road cracks around inspection wells, negative impact on city image, uneven settlement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

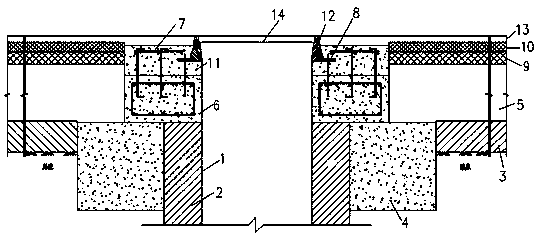

[0039] An inspection well installation and construction process, comprising the following steps:

[0040] (1) Water stability of paved subbase

[0041] a. Before paving the water stability of the subbase, build a reinforcement layer 2 on the outer wall of the well circle 1, build the reinforcement layer to the top elevation of the water stability 3 of the subbase, and cover and close the inner wall opening of the well circle with a precast concrete temporary cover , to prevent the water from falling into the well when the paving water is stable;

[0042] b. Carry out water-stabilized paving of the subbase at the bottom of the pavement and around the well circle;

[0043] (2) Cutting and reverse excavation of the first well circle

[0044] When the water and water stability strength of the subbase reaches 50%, use the total station to stake out the center of the well circle, take the center of the well circle as the center, and draw a circle with the concrete pouring range of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com