A kind of construction site construction concrete steel structure and construction pouring method

A construction site and concrete technology, applied in building construction, construction, building material processing and other directions, can solve the problems of heavy components, many hidden safety hazards, and many cross-operations, etc., and achieve strong compressive and tensile strength, easy to use The effect of fixed connection and simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

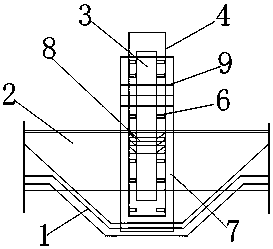

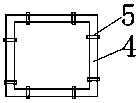

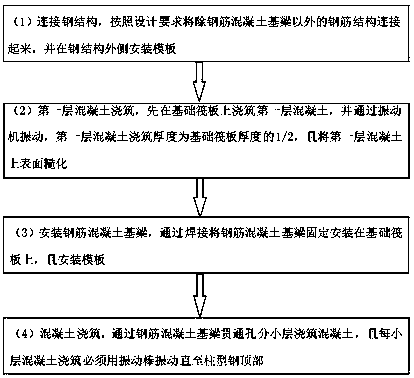

[0024] Embodiment 1: A construction site construction concrete steel structure, including a foundation raft 1, the cross-sectional shape of the foundation raft 1 is U-shaped, and gradually opens from the bottom upward to the outside, and the top of the foundation raft 1 A reinforced concrete base beam 2 is also installed, and a column-shaped steel 3 is installed at the center of the foundation raft 1, and the outside of the column-shaped steel 3 is provided with a steel bar layer 4, and the steel bar layer 4 is fixed and hinged together by tie wires 5, And the hinge specification of the steel bar layer 4 is 1000 mesh, and the column outer stirrup 6 is also arranged between the column shaped steel 3 and the steel bar layer 4, and the column outer stirrup 6 is orthogonal to the steel bar layer 4 and the column shaped steel 3 And they are connected together by welding, and the connection between the reinforced concrete base beam 2 and the column steel 3 is connected through the th...

Embodiment 2

[0031] Embodiment 2: The difference from Embodiment 1 is: a construction site construction concrete steel structure, the distance between the column steel and the reinforcement layer is 1500mm, and the distance between the T-shaped steel and the reinforced concrete base beam is 800mm.

[0032] A concrete pouring method for construction site construction, in the step (1), the distance between the formwork and the outer steel structure is 7.5cm; in the steps (2) and (4), the vibration machine The vibration time is 25 seconds, and the construction time between step (2) and step (4) is 2h.

Embodiment 3

[0033] Embodiment 3: The difference from Embodiment 1 is: a construction site construction concrete steel structure, the distance between the column steel and the reinforcement layer is 1600mm, and the distance between the T-shaped steel and the reinforced concrete base beam is 850mm.

[0034] A concrete pouring method for construction site construction, in the step (1), the distance between the formwork and the outer steel structure is 10cm; in the steps (2) and (4), the vibrating machine vibrates The time is 30 seconds, and the construction time between step (2) and step (4) is 3h.

[0035] It should be noted that the steel structure of the present invention is multi-layer superimposed, that is, all the steel structures are not assembled at the beginning, but during the concrete pouring process, the steel bars are bundled while pouring the concrete. The first feature is mainly manifested on the concrete foundation beam, which is mainly because the concrete foundation beam is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com