Well repair self-balancing derrick

A self-balancing and derrick technology, which is applied to drilling equipment, earthwork drilling, supporting devices, etc., can solve the problems of reduced well site land use and increased workload of minor repair operations, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

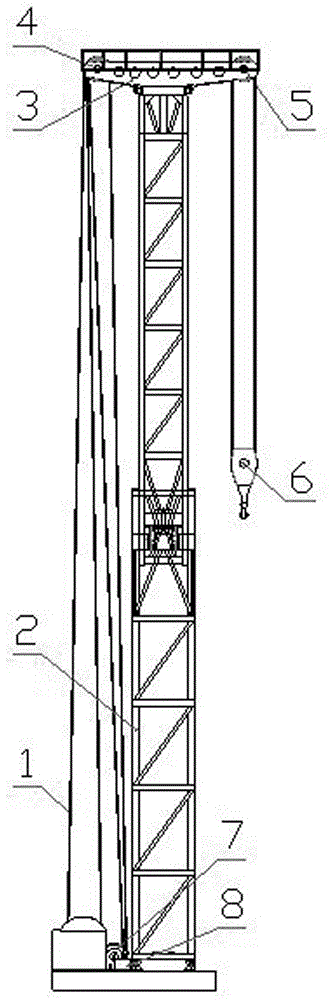

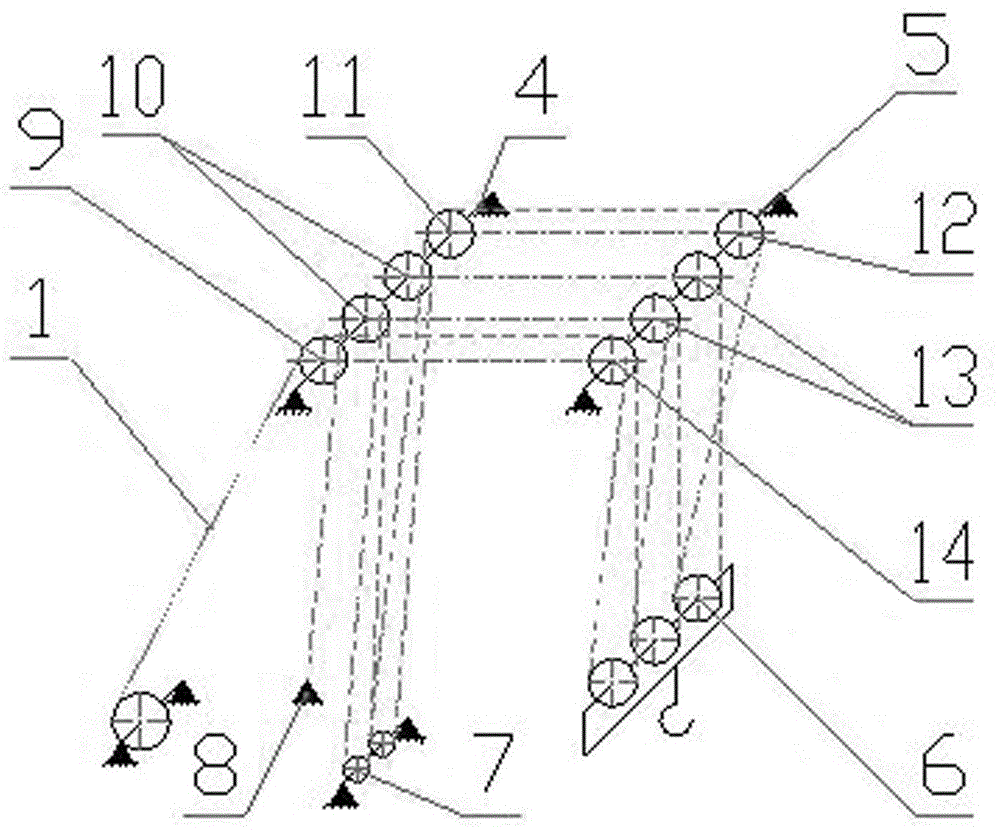

[0013] A workover self-balancing derrick, comprising a steel wire rope 1, a derrick 2, a crown block bracket 3, a rear pulley block 4, a front pulley block 5, a free hook 6, a fixed pulley block 7, and a dead rope end 8. The derrick 2 is vertically installed on the base Or on the vehicle-mounted chassis, there is a crane at the top of the derrick 2, and the crane is composed of a crane bracket 3, a front pulley block 5, and a rear pulley block 4, and the front pulley block 5 and the rear pulley block 4 are located at two ends of the crane bracket 3, wherein The front pulley block 5 and the free hook 6 are on one side, and the rear pulley block 4 and the steel wire rope 1, the fixed pulley block 7, and the dead rope end 8 are on one side; The fast rope pulley 14 on the front pulley block 5 reaches the dead rope pulley 12 on the front pulley block 5 after passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com