A steam turbine medium pressure single-layer welded cylinder structure

A single-layer cylinder and steam turbine technology, applied in the field of steam turbine medium pressure cylinders, can solve the problems of positioning shoulder blade deformation, affecting the economy of the unit, leakage, etc., and achieve the effects of reducing pipeline losses, solving high costs, and improving the uniformity of steam flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

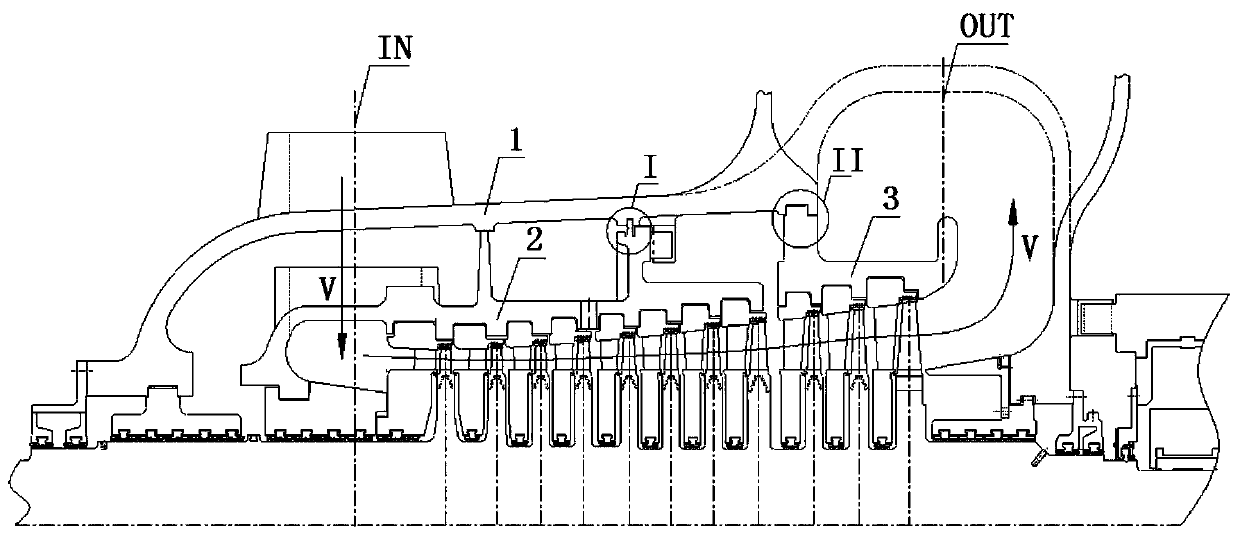

[0028] Such as Figure 7 , Figure 9 The structure of the single-flow medium-pressure cylinder shown in the figure, this single-layer welded medium-pressure cylinder structure is composed of W-V-Nb-N cast steel material in the high-temperature zone 6 of the medium-pressure cylinder and Cr-Mo-V cast steel in the low-temperature zone 7 of the medium-pressure cylinder The materials are welded separately. The W-V-Nb-N cast steel material can withstand high-temperature steam at 600°C to 620°C; the Cr-Mo-V cast steel material can withstand high-temperature steam below 570°C. The weld position P is selected at At the middle pressure third stage partition.

[0029] The steam inlet parameters of the medium-pressure cylinder are 5-8MPa, the reheating temperature is 600°C-620°C, the medium-pressure exhaust steam temperature is 290°C-320°C, and the medium-pressure exhaust steam pressure is 0.5-0.8MPa; the medium-pressure valve 10 Arranged on the running platform on both sides of the cyl...

Embodiment 2

[0034] Such as Figure 8 , Figure 9 The structure of the double-split intermediate pressure cylinder shown in the figure, this single-layer welded intermediate pressure cylinder structure is composed of W-V-Nb-N cast steel material in the high temperature zone 6 of the intermediate pressure cylinder in the middle and Cr-Nb in the low temperature zone 7 of the intermediate pressure cylinder on both sides. Mo-V cast steel materials are welded separately. The W-V-Nb-N cast steel material can withstand high-temperature steam at 600°C to 620°C; the Cr-Mo-V cast steel material can withstand high-temperature steam below 570°C. The seam position P is selected at the middle pressure third stage partition.

[0035] The steam inlet parameters of the medium-pressure cylinder are 5-8MPa, the reheating temperature is 600°C-620°C, the medium-pressure exhaust steam temperature is 290°C-320°C, and the medium-pressure exhaust steam pressure is 0.5-0.8MPa; the medium-pressure valve 10 Arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com