Engine structure for vehicle

A technology for engines and vehicles, which is applied in the direction of engine components, combustion engines, machines/engines, etc., and can solve problems such as adverse effects of engine fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description is merely exemplary in nature, and is not intended to limit the disclosure, application, or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

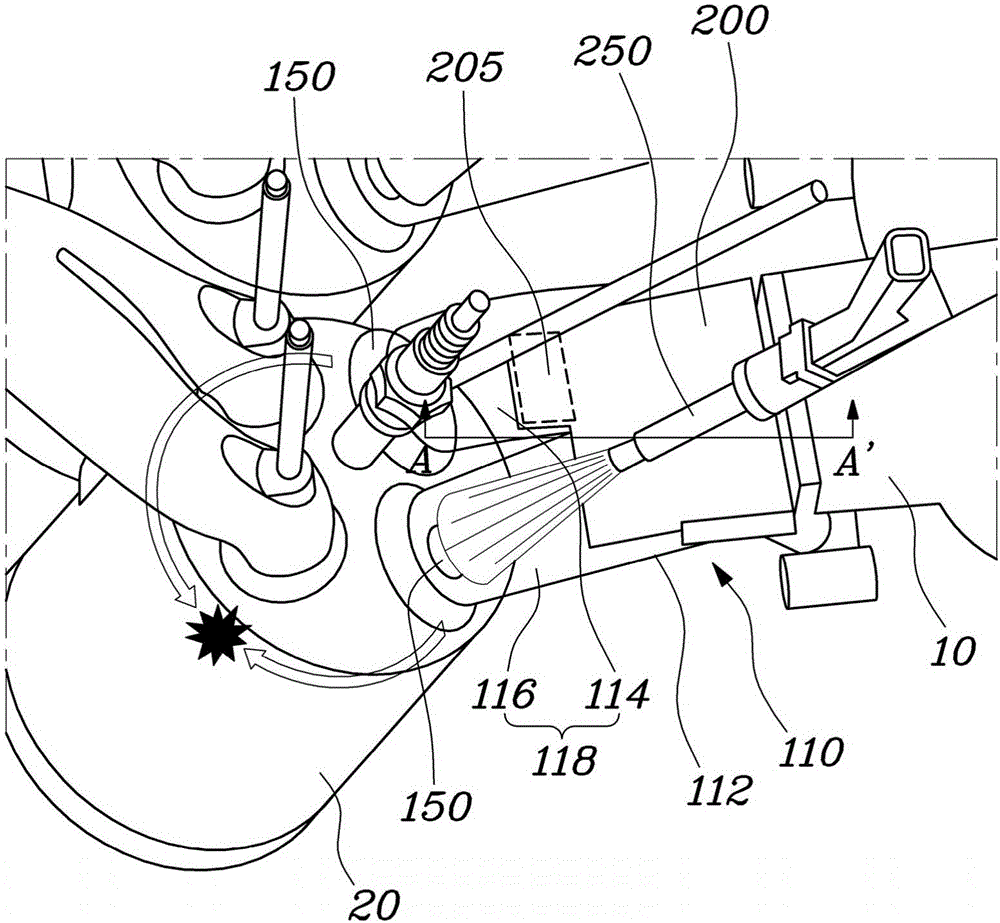

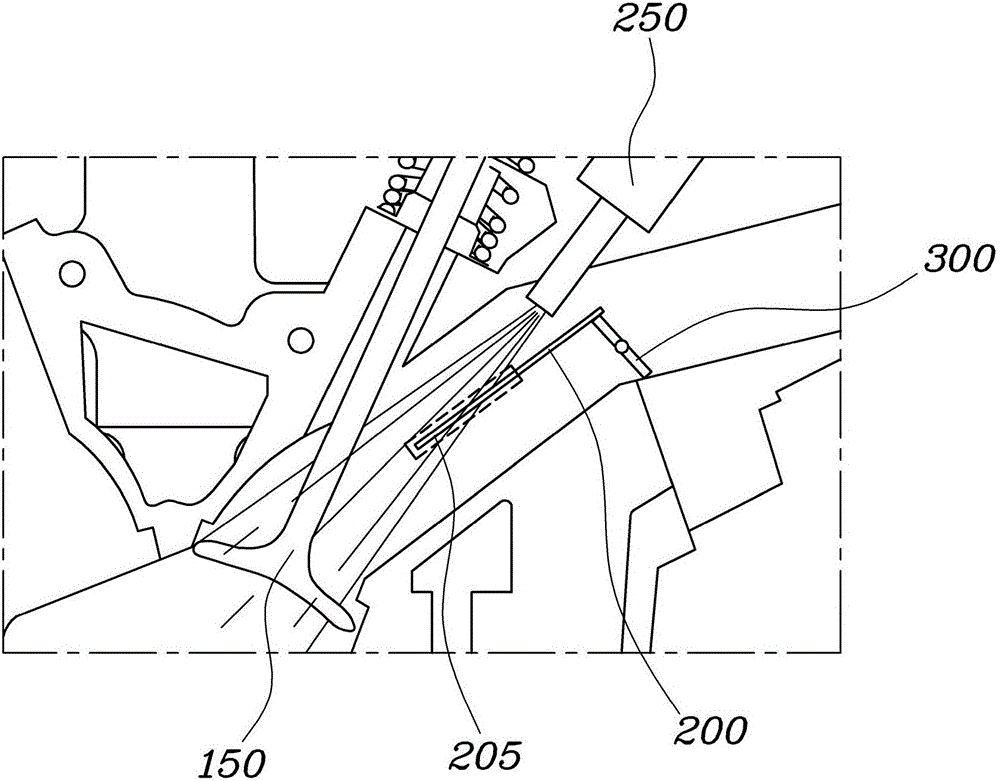

[0022] Figure 1 to Figure 2 An engine structure for a vehicle according to the present disclosure is shown. The engine structure includes: intake port 110 , port plate 200 , and injector 250 . The intake port 110 is configured such that a single flow path 112 in an upstream portion of the intake port branches into a pair of branched flow passages 118 (ie, a pair of branched ports) in a downstream portion of the intake port, and the port plate 200 forms is plate-shaped and disposed in the single flow path 112 of the intake port 110 . Specifically, the port plate 200 is arranged longitudinally parallel to the flow path of the intake port 110 so that the flow path of the intake port 110 is divided into an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com