Mould using for organic binder, molding sand composition and mould

An organic binder and composition technology, which is applied in the directions of casting molds, casting molding equipment, cores, etc., can solve the problems of core molding defects, insufficient casting strength, insufficient effect, etc., so as to increase the casting mold shape. Quantity, suppression of sticky sand "increase, and improve the effect of molding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

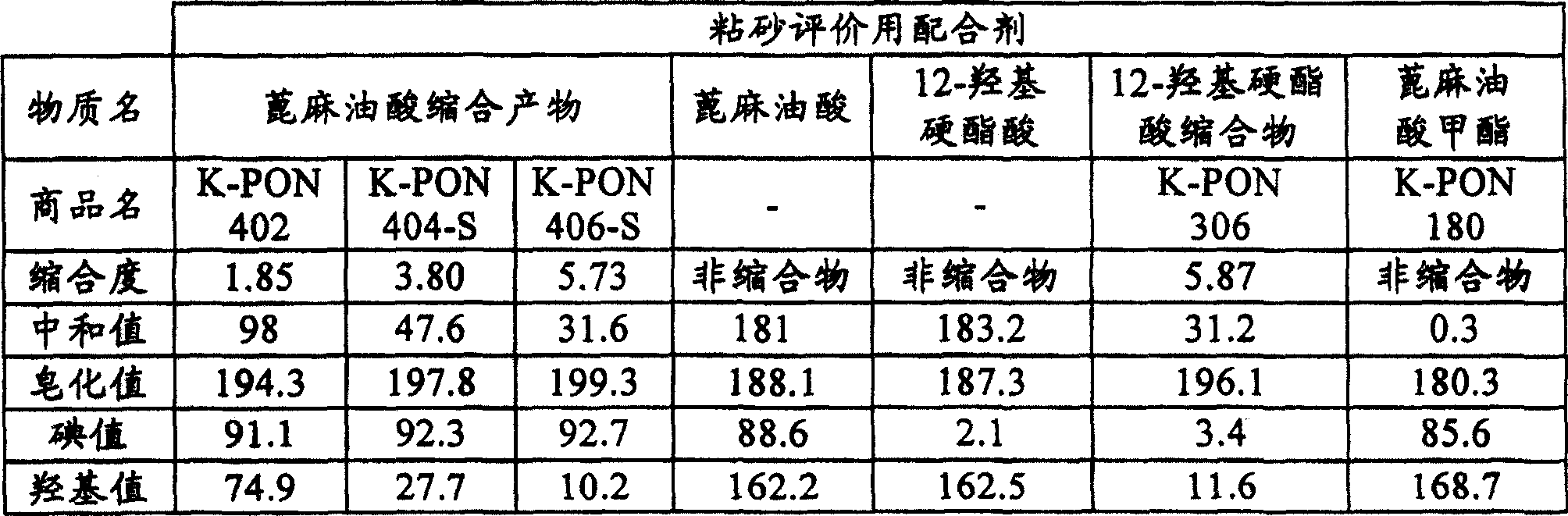

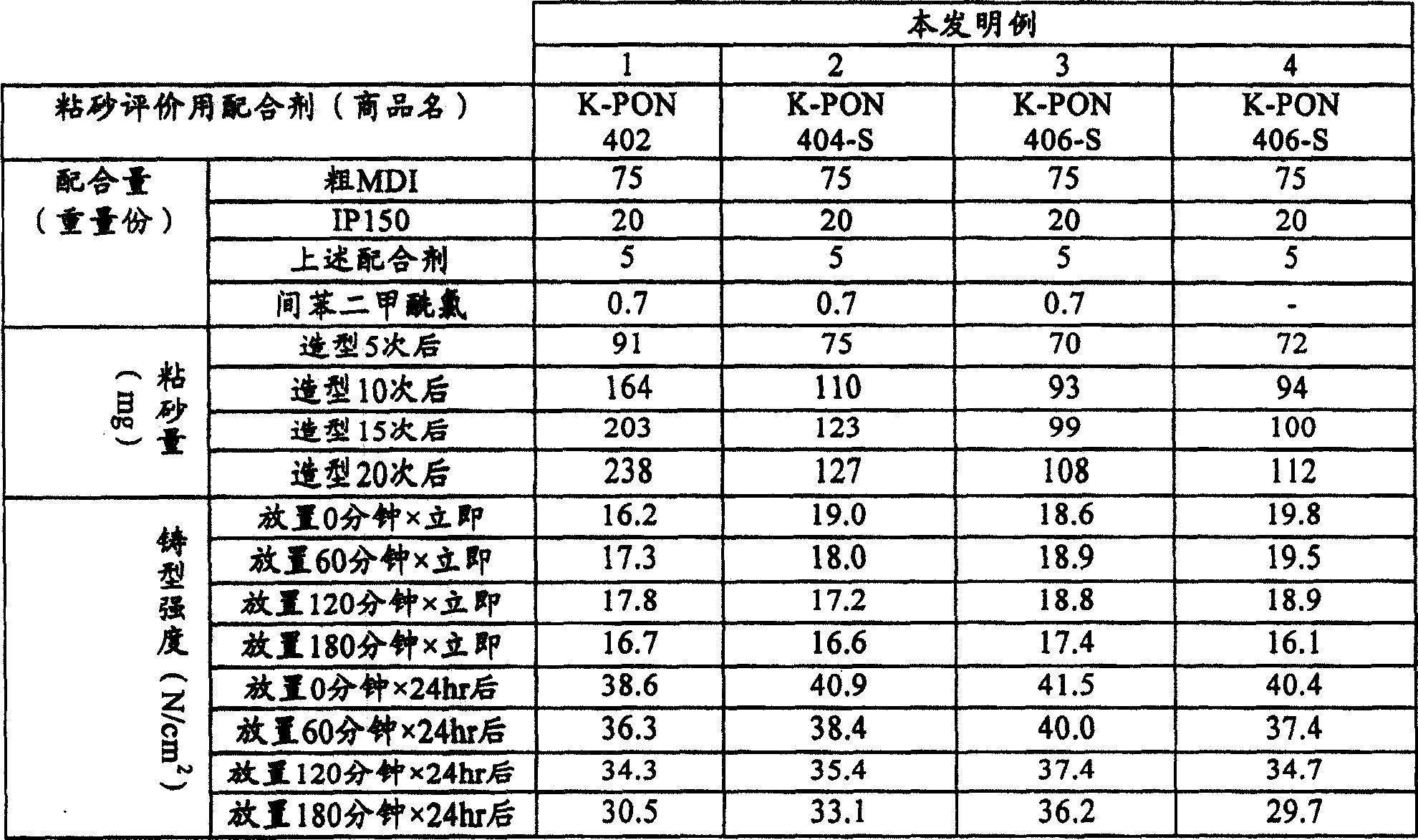

[0072] First, condensed MDI (crude MDI), IPUSOL 150 (IP150; organic solvent) as a polyisocyanate compound, and the compounding agent (substance) for sand sticking evaluation shown in Table 1 above were mixed according to the ratios shown in Tables 2 and 3 below. Mix with isophthaloyl chloride and mix evenly. After preparing various polyisocyanate solutions, stir the polyisocyanate solution at a temperature of 25°C for two days (48 hours). A reaction occurs when a reaction can occur between agents.

[0073] Then, 1000 parts by weight of foundry silica sand, 10 parts by weight of pre-prepared silica sand, which had been left for 24 hours in an atmosphere of temperature: 20° C.×relative humidity: 60%, were put into a Sichuan-type horizontal mixer manufactured by DALTON Co., Ltd. After the phenolic resin solution and 10 parts by weight of polyisocyanate solution mixed with various compounding agents for sand sticking evaluation were stirred and kneaded for 40 seconds, molding sand...

Embodiment 2

[0081] According to the ratio shown in the following table 4, add condensed MDI (crude MDI), IPUSOL 150 (IP 150; organic solvent) as polyisocyanate compound, compounding agent for sand sticking evaluation and isophthaloyl chloride, mix uniformly, Prepare polyisocyanate solutions.

[0082] Then, instead of leaving the prepared polyisocyanate solution for two days as in Example 1, it was directly used with the pre-prepared phenolic resin solution after preparation, and a molding sand composition was prepared in the same manner as in Example 1. Using the obtained molding sand composition, evaluation of sand stickiness and measurement of mold strength were carried out in the same manner as in Example 1, and the results are shown in Table 4.

[0083] [Table 4]

[0084]

[0085] The results in Table 4 clearly show that Example 5 of the present invention using the condensation product of the present invention showed excellent results in improving sand adhesion and mold strength. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com