Variable disc spring support and hanger correction device

A correction device and support and hanger technology, which is applied in the direction of pipe supports, hoses, pipes, etc., can solve the problems of difficult supply of spring materials, inconvenient installation and arrangement, and difficult methods, so as to achieve the effect of improving portability and ensuring the stability of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

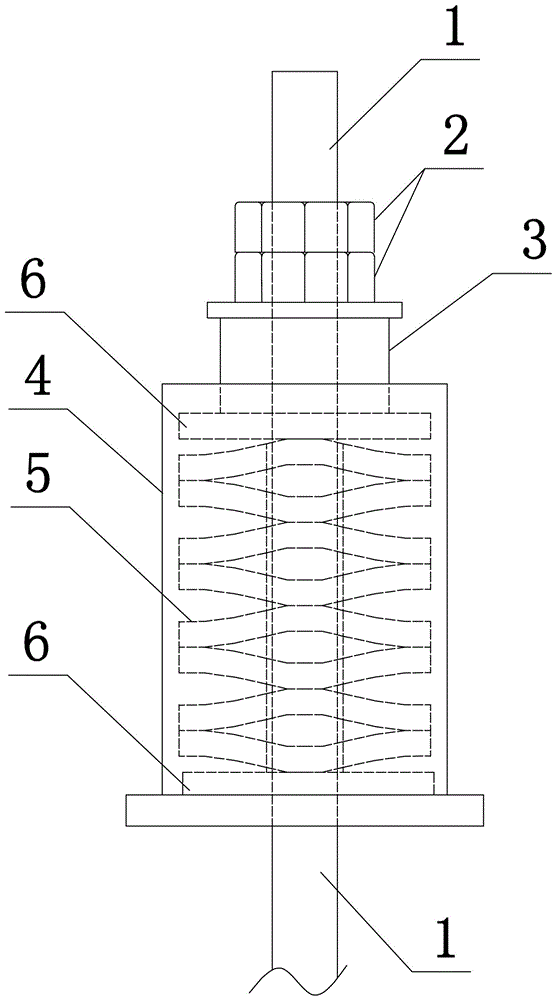

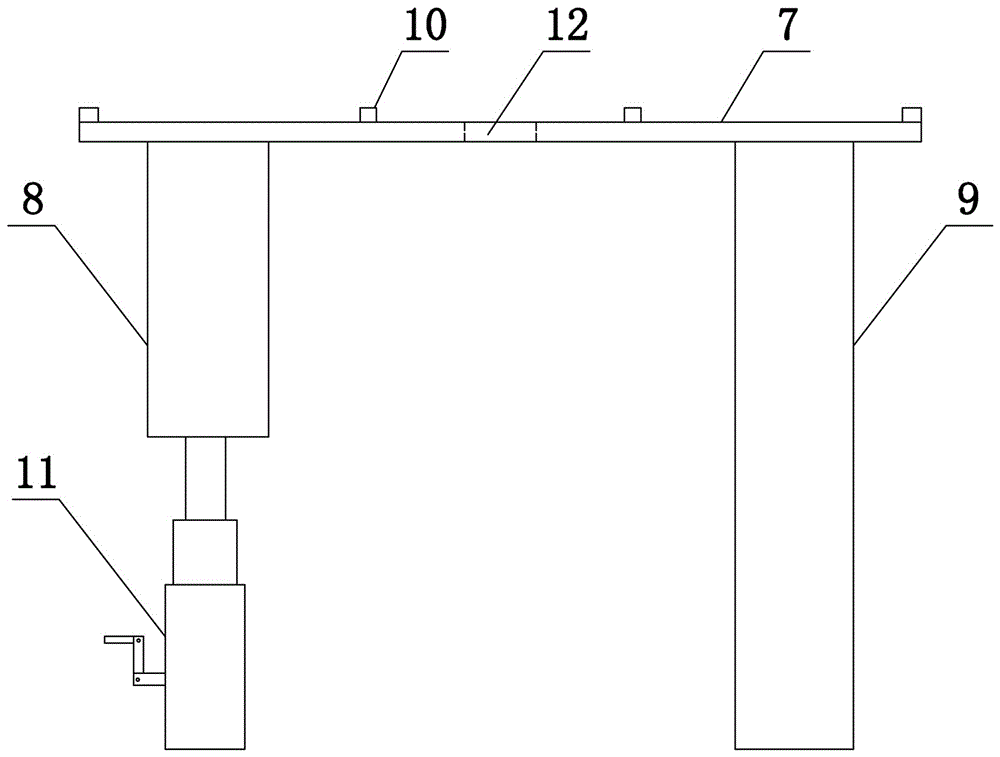

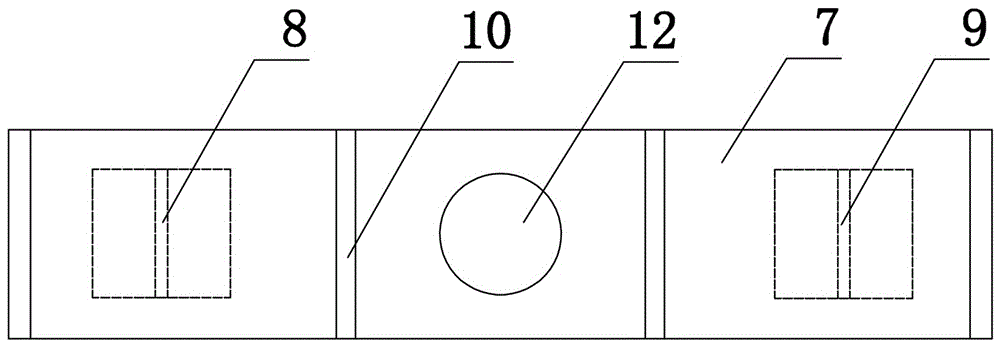

[0031] Such as Figure 2 to Figure 4 As shown, a variable disc spring support and hanger correction device includes a top plate 7, a first outrigger 8 and a second outrigger 9 that are vertically fixedly connected to both sides of the lower end of the top plate 7, and a reinforcing rib 10 is vertically welded on the upper end of the top plate 7. , the first supporting leg 8 and the second supporting leg 9 adopt I-shaped steel, the height of the first supporting leg 8 is less than the height of the second supporting leg 9, the lower end surface of the first supporting leg 8 is provided with a pushing mechanism 11, and the pushing mechanism 11 is Hydraulic jack, top plate 7 center offers through hole 12.

[0032] A method for correcting a correction device for a variable disc spring support hanger, taking the variable disc spring hanger as an example, the calibration method for the variable disc spring support is the same, including the following steps:

[0033] Step 1: Install...

Embodiment 2

[0039] Such as Figure 5As shown, a variable disc spring support and hanger correction device includes a top plate 7, a first leg 8 and a second leg 9 that are vertically fixedly connected to both sides of the lower end of the top plate 7, and the lower end of the first leg 8 is provided with a circular Accommodating groove 14, arc-shaped accommodation groove 15 is arranged on the lower end surface of the second supporting leg, and the arc-shaped accommodation groove 15 is rotated to connect the supporting legs. The backing plate 18 at the lower end of the connecting plate 17, the backing plate 18 is a trapezoidal structure, the upper end of the top plate 7 is vertically welded with reinforcing ribs 10, the first leg 8 and the second leg 9 adopt I-shaped steel, and the height of the first leg 8 is less than The height of the second support leg 9, the lower end surface of the first support leg 8 is provided with a push-off mechanism 11, the push-off mechanism 11 is a hydraulic ...

Embodiment 3

[0041] Such as Image 6 with Figure 7 As shown, a variable disc spring support and hanger correction device includes a top plate 7, a first leg 8 and a second leg 9 that are vertically fixedly connected to both sides of the lower end of the top plate 7, and the lower end of the first leg 8 is provided with a circular Accommodating groove 14, arc-shaped accommodation groove 15 is arranged on the lower end surface of the second supporting leg, and the arc-shaped accommodation groove 15 is rotated to connect the supporting legs. The backing plate 18 at the lower end of the connecting plate 17, the backing plate 18 is a trapezoidal structure, the two front and rear edges of the upper end of the top plate 7 are welded with vertical plates 21, four reinforcement plates 22 are welded between the two vertical plates 21, and the first leg 8 and the second support leg 9 are made of I-shaped steel, the height of the first support leg 8 is smaller than the height of the second support l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com