Solidified latent heat acquiring device and system

A collection device and latent heat technology, applied in the energy field, can solve the problems of difficult to achieve continuous extraction of solidification heat for heating, difficult peeling, thick ice layer, etc., and achieve the effects of continuous and uninterrupted safe operation, reduced operating costs, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

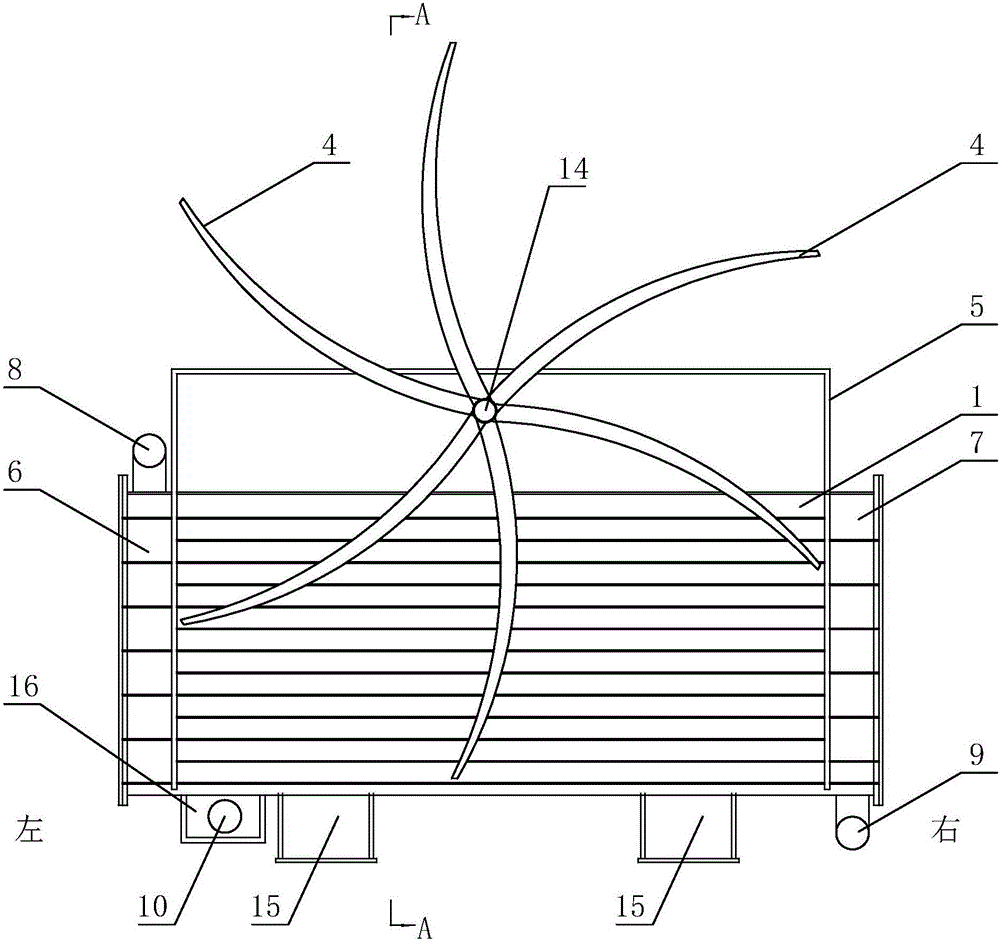

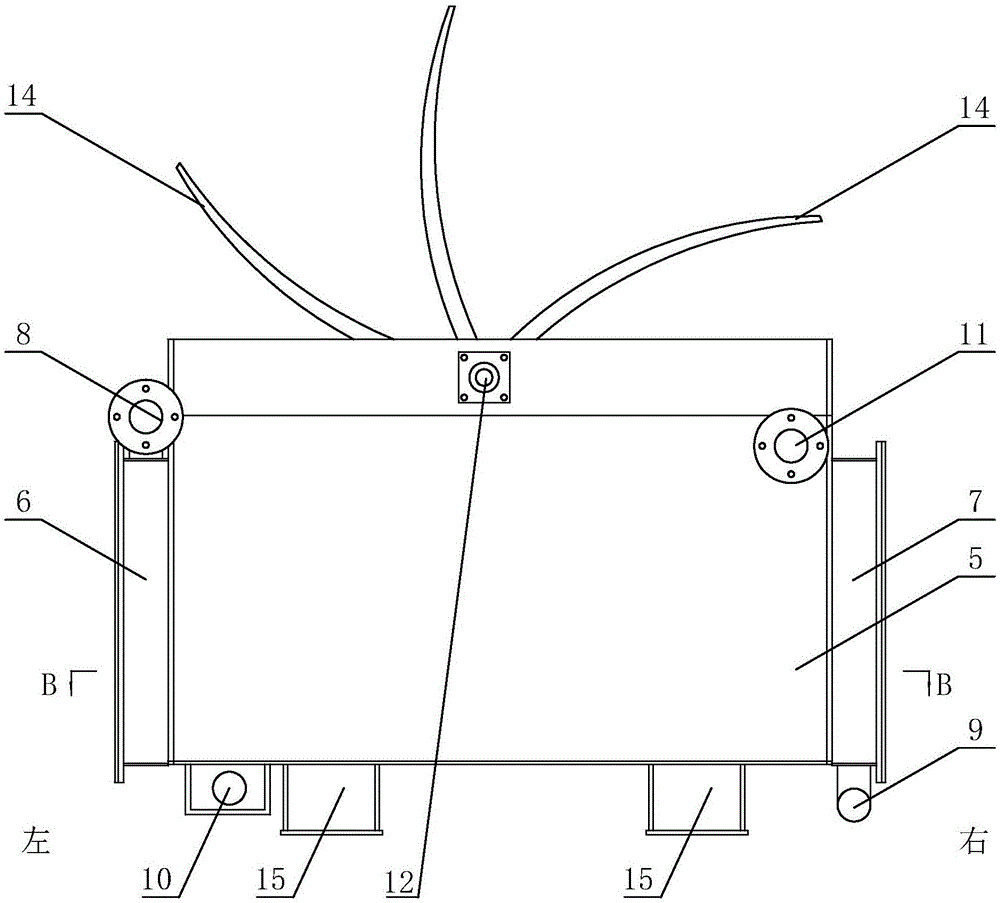

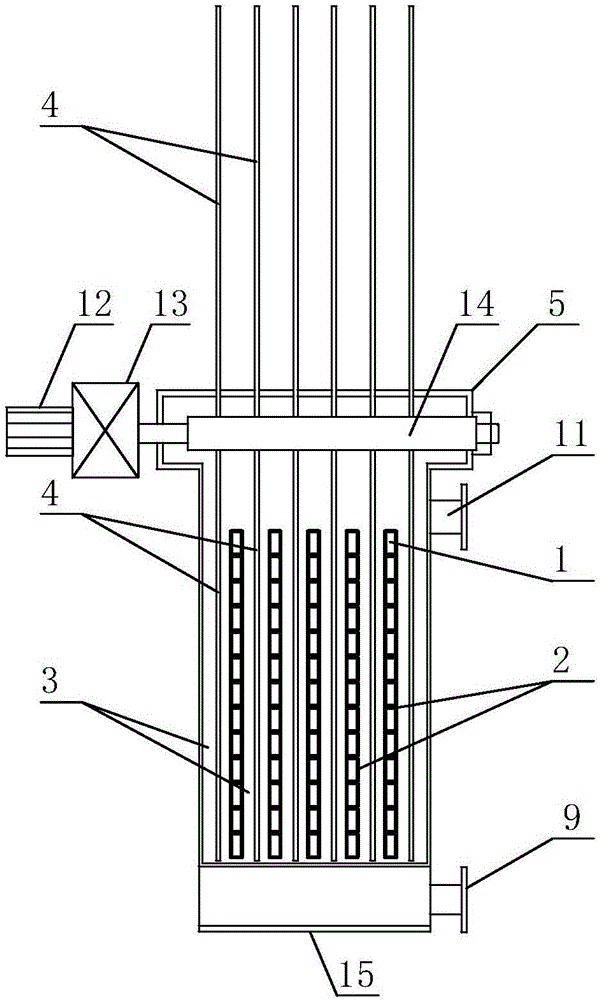

[0032]Specific implementation mode one, such as Figure 1~3 As shown, a solidification latent heat collection device of this embodiment is composed of heat exchange tube 1, tube row 2, cold water flow channel 3, scraper 4, housing 5, left header 6, right header 7, and antifreeze solution inlet 8. Antifreeze solution outlet 9, cold water inlet 10, cold water outlet 11, motor 12, reducer 13, main shaft 14, footing 15, cold water inlet chamber 16 and multiple cold water inlets 17. The heat exchange tubes 1 form a tube row 2 in the vertical direction, and the two ends of a plurality of heat exchange tubes 1 are respectively connected with the left header 6 and the right header 7; between the two tube rows 2, the tube row 2 There is a cold water channel 3 between the housing 5; one end of the scraper 4 is connected to the main shaft 14 and the blade of the scraper 4 is arranged in the cold water channel 3; the left end of the housing 5 is connected to the left header 6 The right e...

specific Embodiment approach 2

[0033] Embodiment 2. In the solidification latent heat collection device of this embodiment, the antifreeze aqueous solution flows back and forth from left to right and from top to bottom under the action of the left header 6 and the right header 7 .

specific Embodiment approach 3

[0034] Specific implementation mode three, such as Figure 4 As shown, in a solidification latent heat collection device of this embodiment, the cold water inlet chamber 16 is connected to the cold water inlet 10; and each cold water inlet port 17 communicates with the cold water inlet cavity 16 and the corresponding cold water flow channel 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com