Application method of machine room dehumidifying mechanism

A technology for a computer room and a casing, applied in the field of dehumidifiers, can solve the problems affecting the normal operation of electrical equipment in the computer room, the erosion and oxidation of the humid air of the heat exchanger, and the damage of the heat exchanger, so as to achieve continuous and stable dehumidification performance, improve dehumidification efficiency, The effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

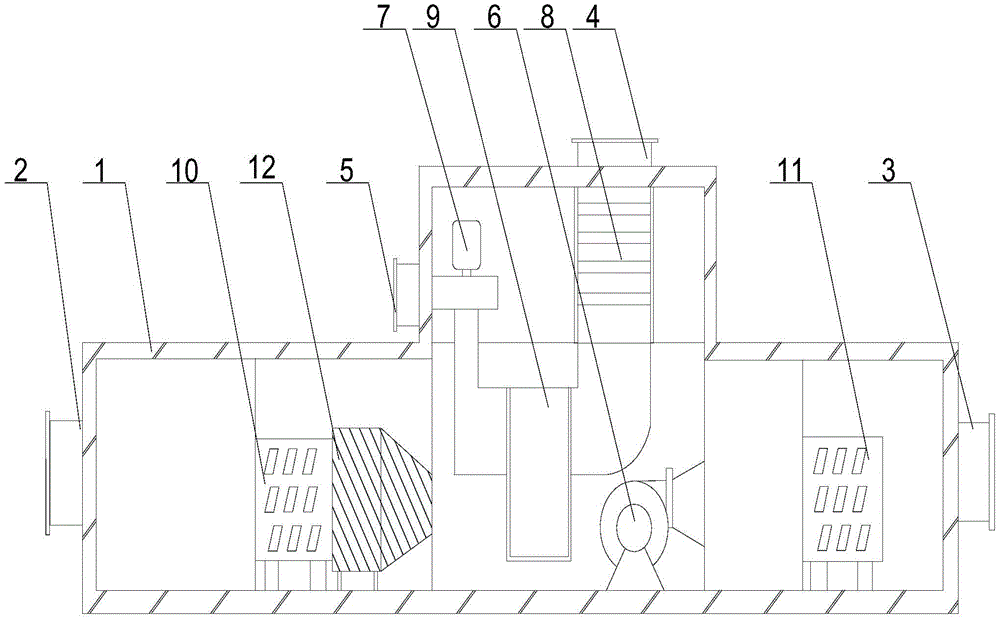

[0024] Such as figure 1 with figure 2 Shown, the present invention comprises the following steps:

[0025] A The cold air in the operating room enters the dehumidification wheel through the air inlet;

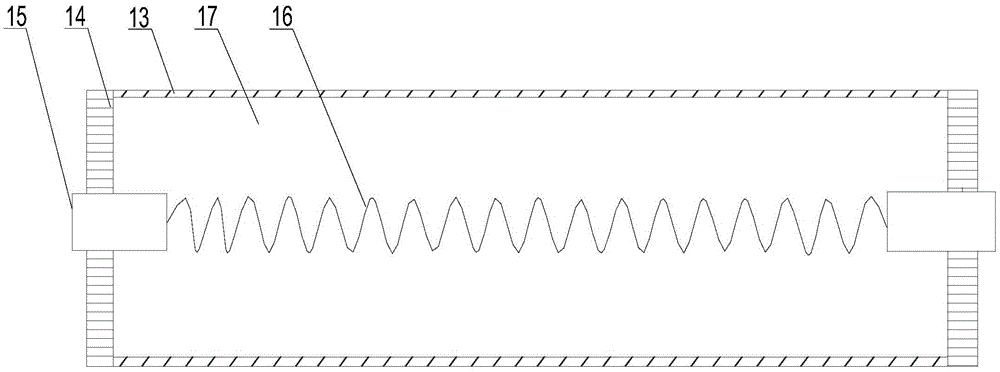

[0026] B The front cooler processes the indoor air in the first step, and the treated air enters the funnel-shaped water retaining pan. Since the outer diameter of the water retaining plate decreases along the direction of air flow, a small amount of water vapor in the passing air Coagulate on the inner wall of the disk, and the condensed water droplets are discharged into the casing through the annular groove;

[0027] C The humid air in the operating room is processed in the treatment area, the dehumidification wheel is driven to rotate slowly, and the saturated water vapor in the treatment area enters the regeneration area;

[0028] D Inject fresh air through the regenerative air inlet, and the heater will heat the fresh air;

[0029] E Finally, the dry air is discharge...

Embodiment 2

[0034] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, a front cooler 10 and a rear cooler 12 are installed in the casing 1, the front cooler 10 is arranged on the air inlet 2, and the rear cooler 12 Set on the air outlet 3. The air humidity in the operation room of the machine room is relatively high. Before passing through the dehumidification rotor 9, the air is pretreated by the front cooler 10 to reduce the water vapor content in the air, and at the same time improve the working efficiency of the dehumidification rotor 9. When the air passes through the dehumidification rotor After the wheel 9, a small amount of water vapor remaining in the air is cleaned up by the after cooler 12 to ensure that the air that flows back into the operating room is dry and improves a stable working environment for electrical equipment; the present invention adopts three-stage dehumidification means to ensure the best air dehumidification effect every time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com