Patents

Literature

88results about How to "Reduce the presence of moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

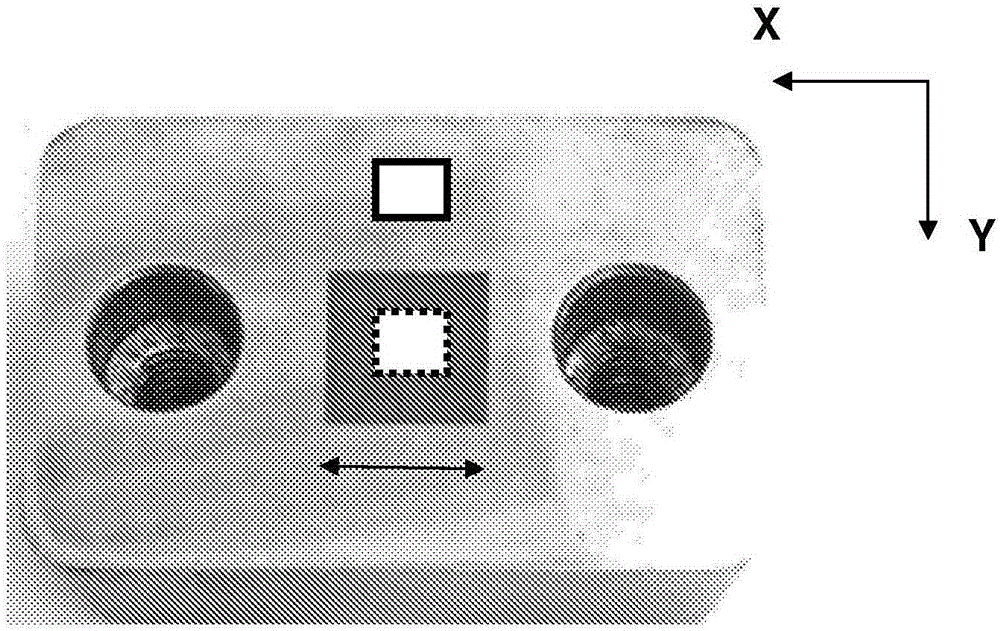

Packaging method of OLED (Organic Light Emitting Diode) and OLED packaging structure

InactiveCN104538566AImprove sealingIncrease contact areaSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceWater vapor

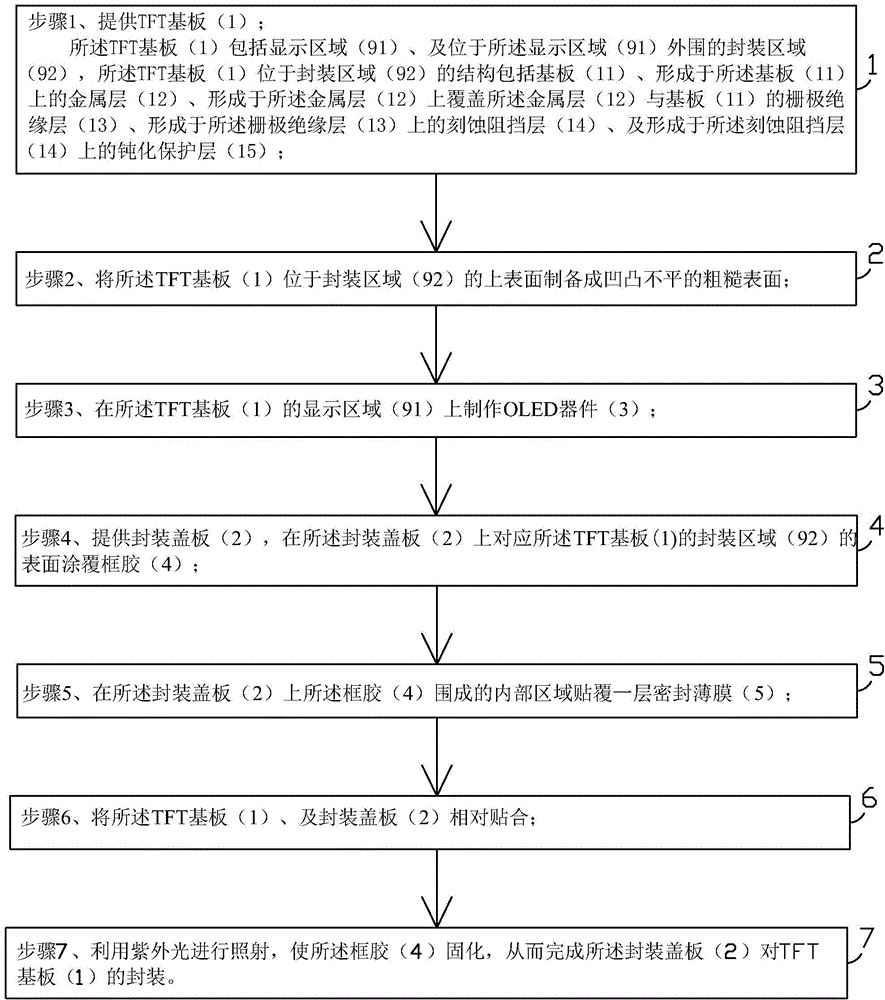

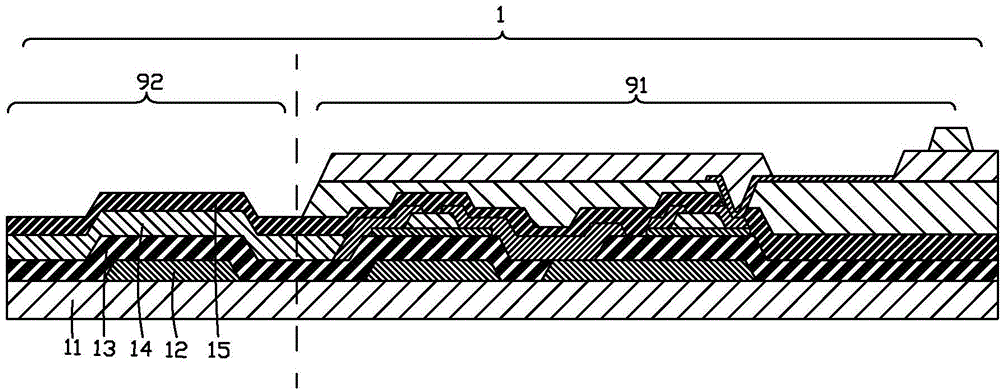

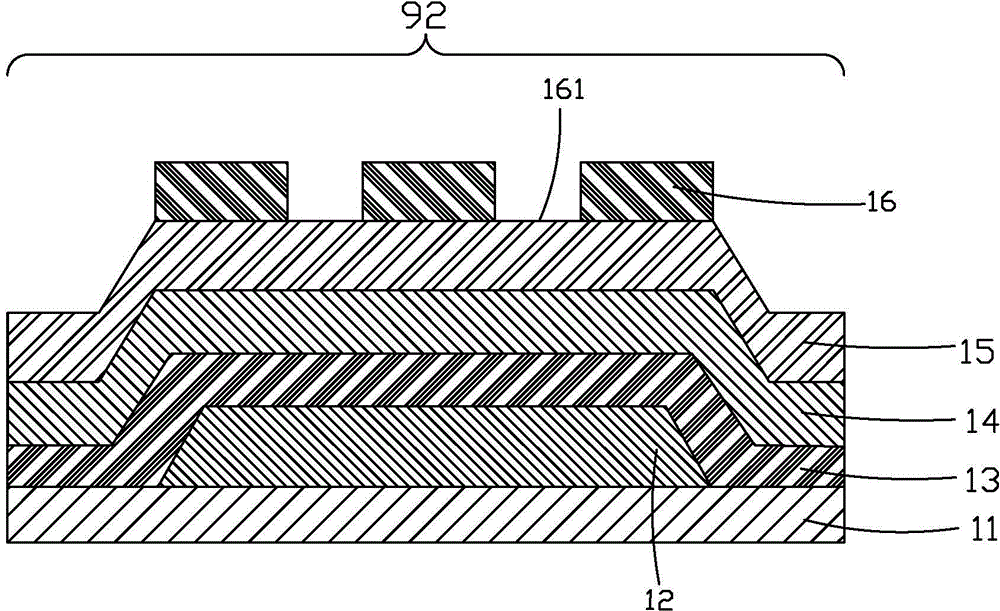

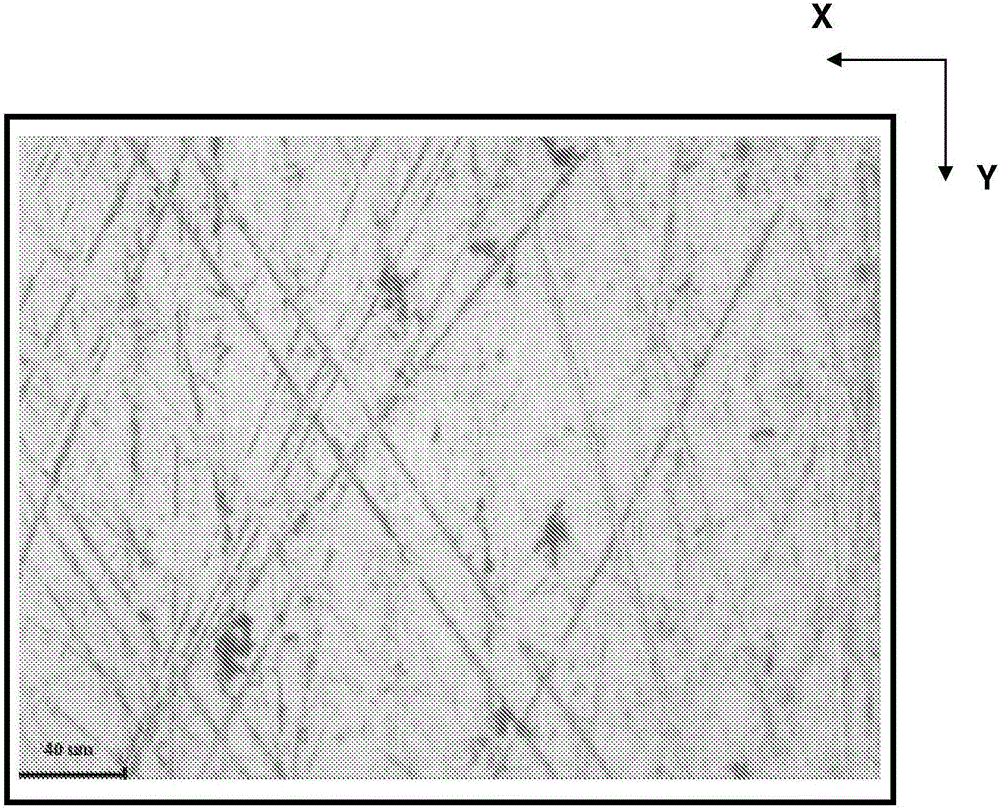

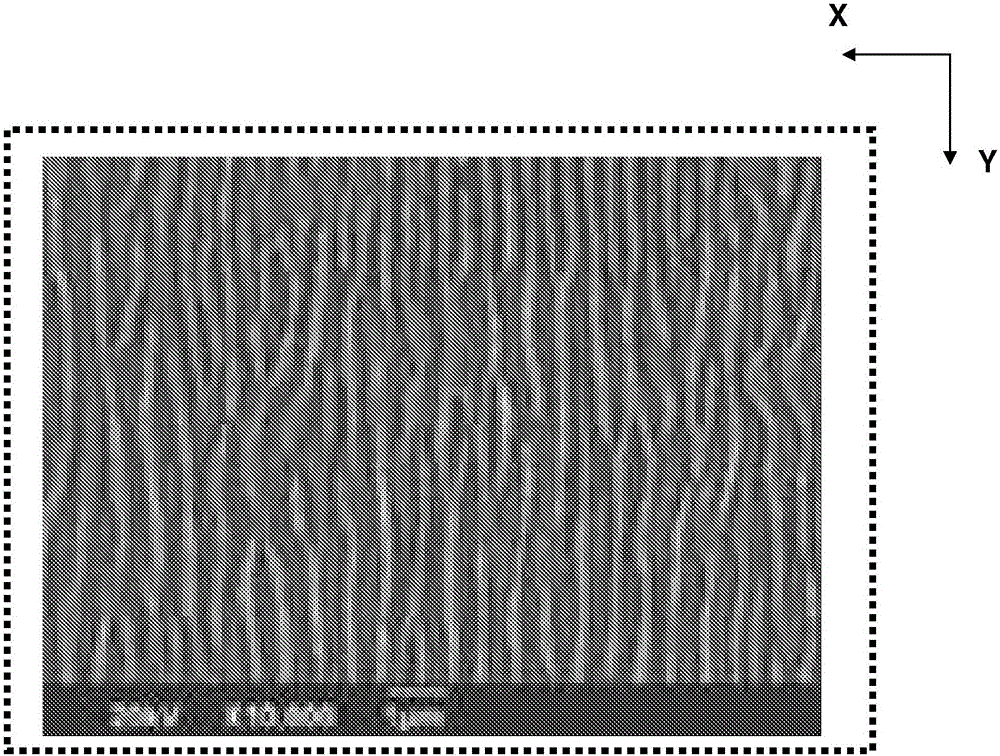

The invention provides a packaging method of an OLED (Organic Light Emitting Diode) and an OLED packaging structure. The packaging method and the packaging structure provided by the invention have the advantages that the upper surface of a packaging area of a TFT (Thin Film Transistor) substrate is prepared into an uneven and rough surface, so that the contact area between frame glue and the TFT substrate is enlarged and the adhesive force between the packaging cover plate and the TFT substrate is enhanced; a sealing thin film which covers the OLED device and fills the internal space enclosed by the frame glue is arranged in the OLED packaging structure, so that the sealing performance of the OLED packaging structure is improved, oxygen and the water vapor permeating into the OLED are effectively reduced, the performance of the OLED device is improved and the service life of the OLED device is prolonged.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

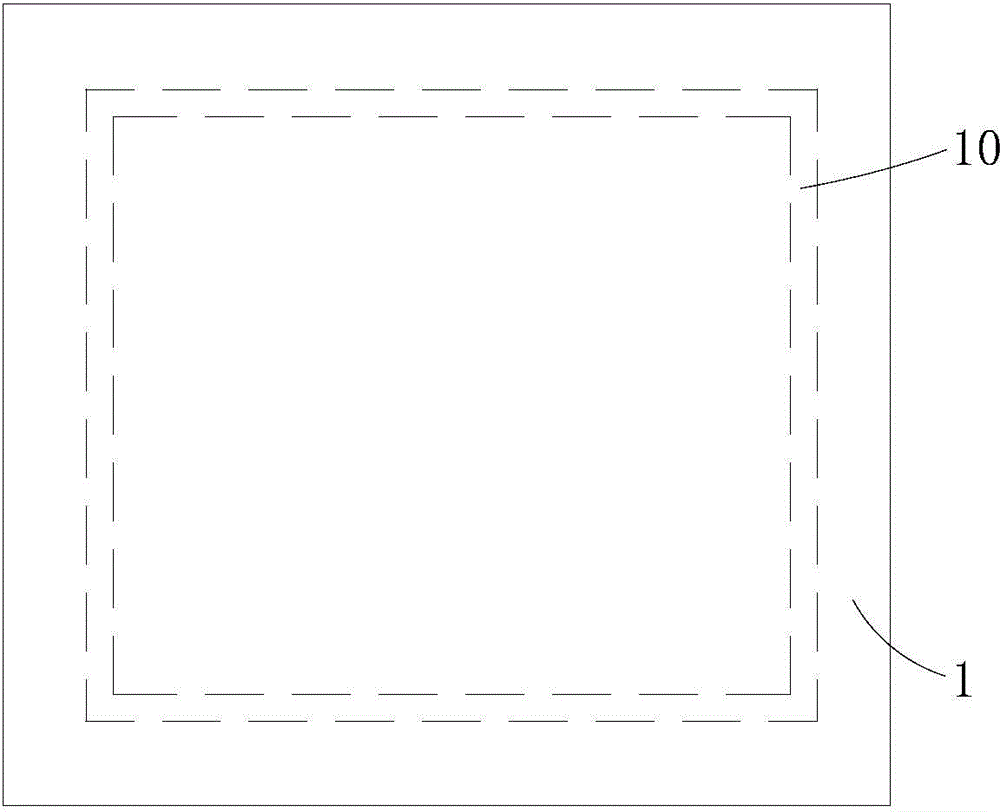

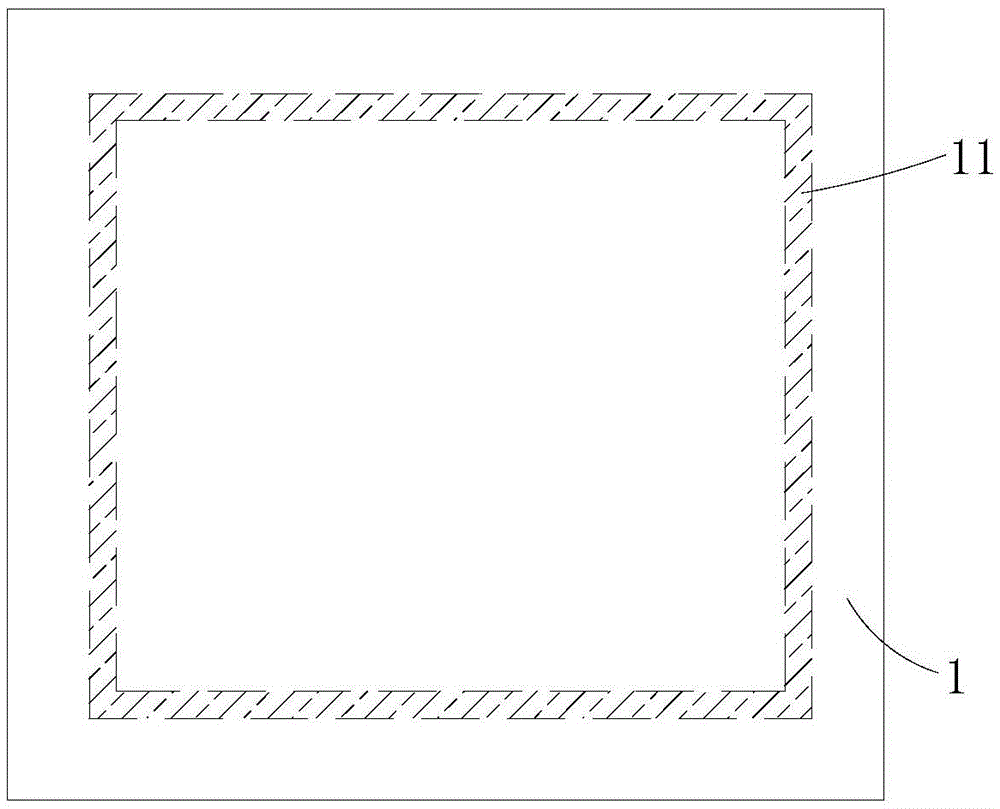

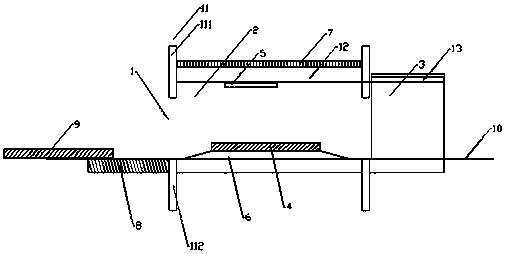

OLED (organic light-emitting diode) packaging method and OLED packaging structure

InactiveCN104576972AIncrease contact areaImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceLiquid state

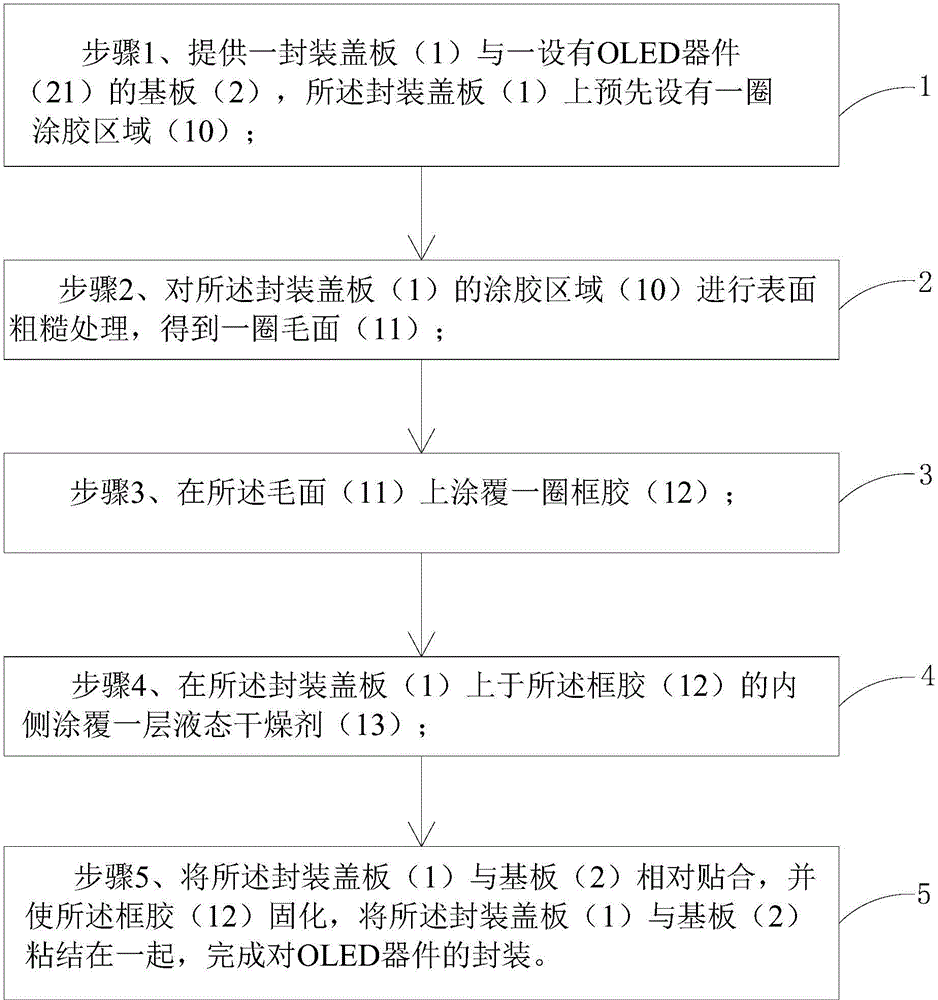

The invention provides an OLED (organic light-emitting diode) packaging method and an OLED packaging structure. The OLED packaging method comprises the following steps: step 1, providing a packaging cover plate (1) and a base plate (2) provided with an OLED device (21), wherein a circle of glued region (10) is pre-arranged on the packaging cover plate (1); step 2, performing surface roughening treatment on the glued region (10) of the packaging cover plate (1) to obtain a circle of rough surface; step 3, coating a circle of frame glue (12) on the rough surface (11); step 4, coating a layer of a liquid-state drying agent (13) on the inner side of the frame glue (12) on the packaging cover plate (1); step 5, relatively jointing the packaging cover plate (1) with the base plate (2) to cure the frame glue (12) and bonding the packaging cover plate (1) and the base plate (2) together to complete packaging of the OLED device. By adopting the method, the bonding force between the packaging cover plate and the base plate can be significantly packaged, and the sealing property is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Process for producing taurine drying and sterilizing by microwave and high-efficiency ebullition

InactiveCN101333177AEfficient killingImprove efficiencyOrganic compound preparationSulfonic acid preparationCentrifugationFiltration

A processing technology for producing taurine through microwave and high-performance boiling combined dry sterilization comprises addition, adjustment, synthesis, flash evaporation, pre-steaming, evaporation, neutralization and crystallization, filtration, purification, decolorization, fine filtration, centrifugation, drying, crushing and finished product packaging. The processing technology is characterized in that the processing technology comprises the following steps: the centrifugal wet high-quality product enters into a tunnel microwave drying machine for microwave drying sterilization, wherein, the temperature is controlled to 80-100 DEG C, while the time is controlled to 3-8 minutes; the product then enters into an efficient boiling machine for dry sterilization, with the temperature at 110-130 DEG C and the drying time for 1-1.5 hours. If the drying time for the efficient boiling dry sterilization is shorted, the direct use of efficient boiling sterilization drying time is around 1 hour and 40 minutes. If microwave drying followed by high-performance boiling drying, only one hour is enough. The processing technology has the advantages that the efficient boiling drying sterilization adopts pasteurization; a better effect can be achieved by cross-sterilization through microwave sterilization and efficient boiling drying sterilization. The material has slight caking through microwave, while the caking can be completely broken after efficient boiling drying sterilization to reduce the loss of the materials in the late stage.

Owner:SHAYANG TIANYI MEDICINE IND

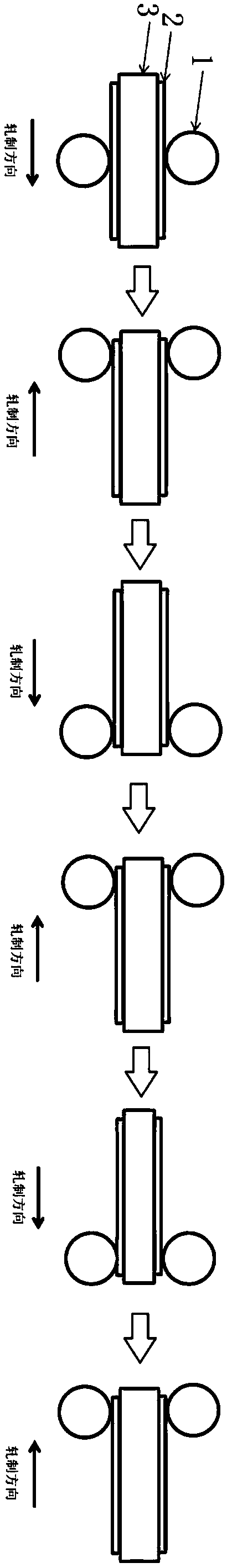

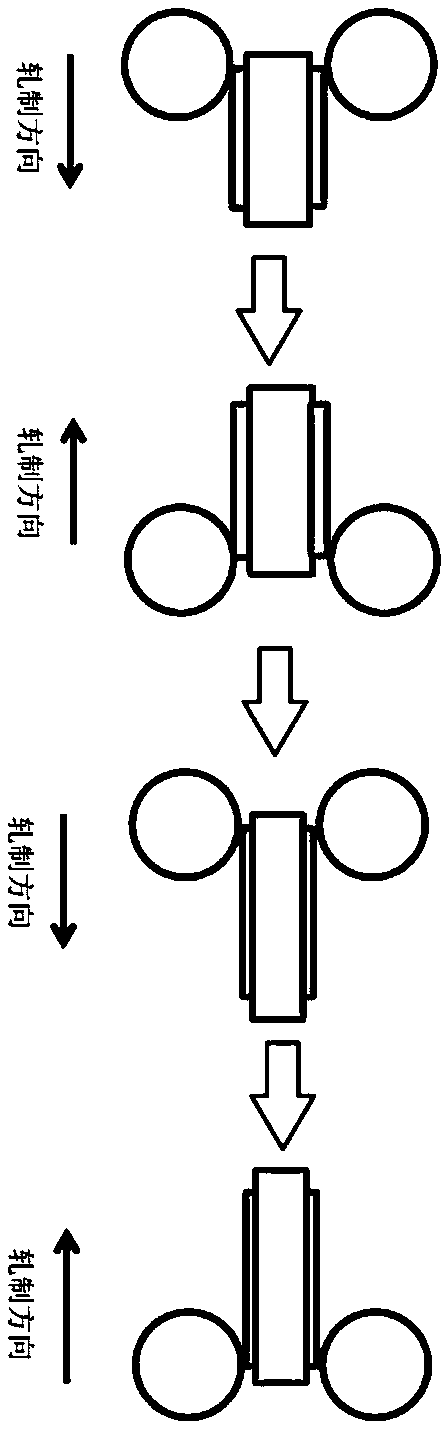

Rolling method for producing wide-width packaging aluminum plate

ActiveCN109092894AReduce the presence of moistureHeating smoothlyRoll mill control devicesMetal rolling arrangementsEmulsionWorking temperature

The invention discloses a rolling method for producing a wide-width packaging aluminum plate. The rolling method mainly comprises the steps that (1), the specifications of a skin material and a core material are determined and the width and length of the skin material are smaller than that of the core material, and the upper and lower surface of the core material are coated with and fixed to the skin material to form composite ingots; (2), the composite ingots are heated by a two-stage type heating institution; (3), a mill roll is preheated to the working temperature; and (4), rolling is performed, specifically, primary longitudinal rolling, transverse rolling and secondary longitudinal rolling are performed in sequence. By controlling an emulsion at the initial stage of rolling and matching the key process parameters such as the rolling reduction of each pass and the rolling speed, the three factors are closely matched to ensure the smooth operation of rolling, broadsiding and coating; and the width of the packaging aluminum plate is not limited by the width of the ingot casting. Compared with an existing conventional process, the rolling method can produce wider packaging aluminum thin panels, shortens the processing process, improves the production efficiency, improves the surface quality, and achieves the goal of reducing the defects such as emulsion marks, color differenceand black strips.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

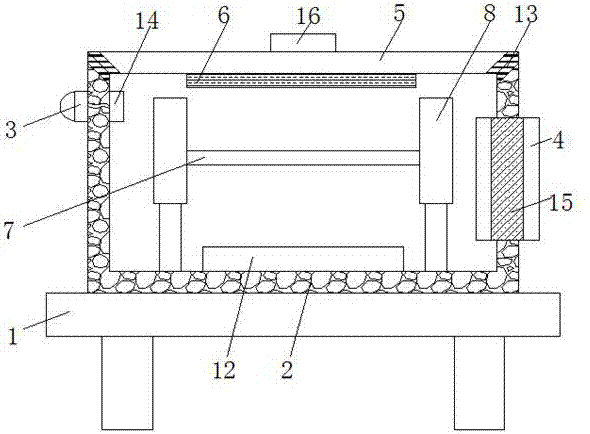

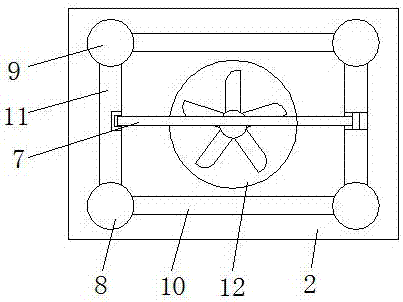

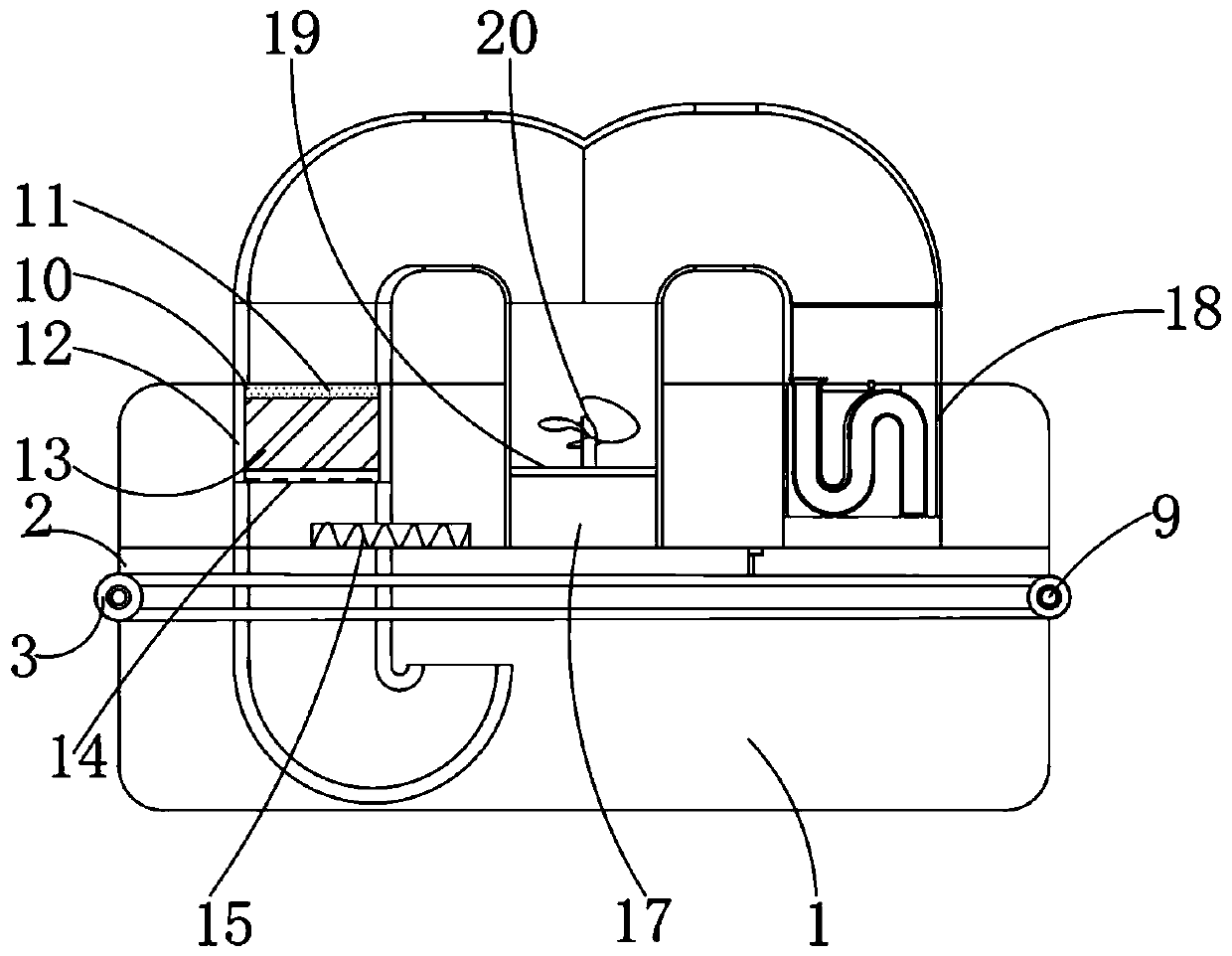

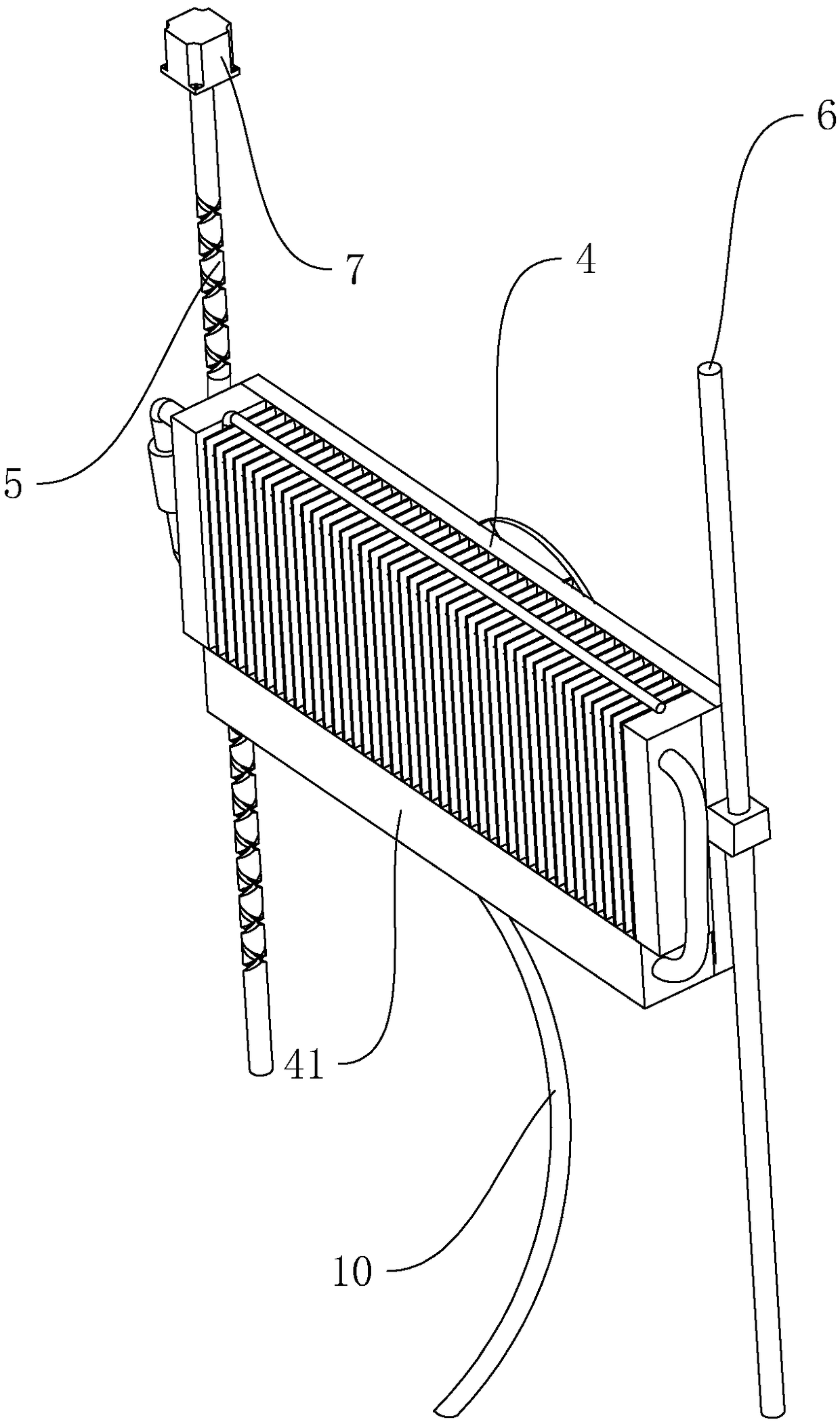

Device used for cooling sheet-shaped laser gain media

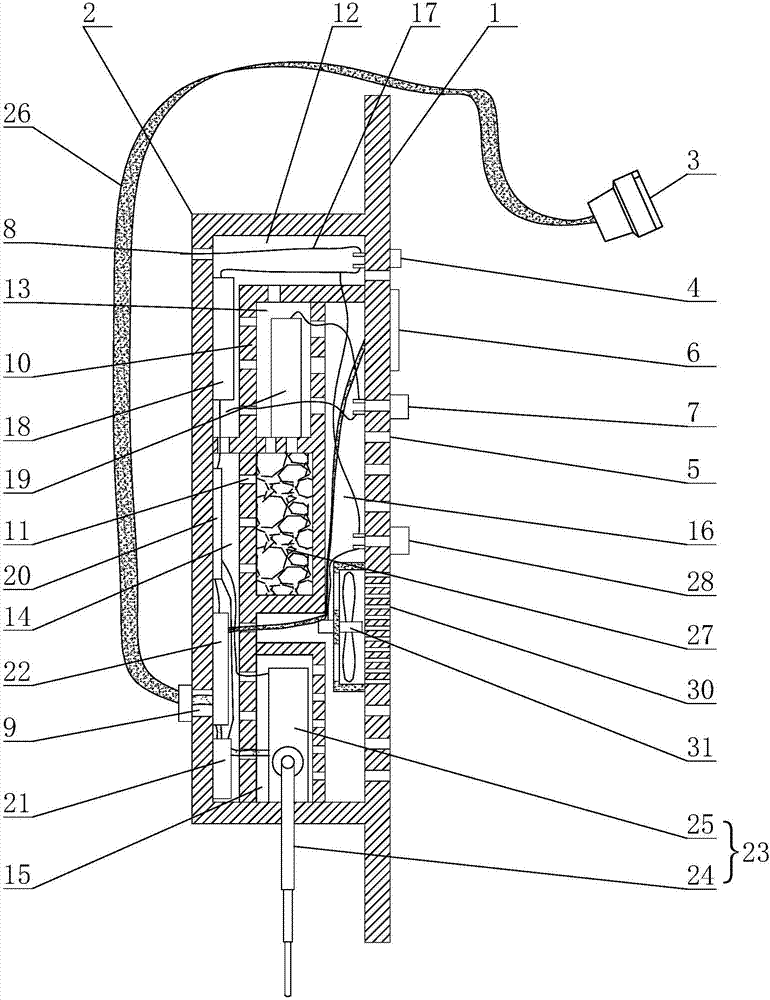

InactiveCN103474865AControl working temperatureReduce the presence of moistureLaser detailsVacuum pumpingWater channel

The invention discloses a device used for cooling sheet-shaped laser gain media. The device comprises a heat sink, a TEC, a vacuum chamber shell, a vacuum chamber base and a covering board; the vacuum chamber shell is in a tube shape, the heat sink and the TEC are located inside the vacuum chamber shell, one end of the vacuum chamber shell is connected with the vacuum chamber base in a sealed mode, and the other end of the vacuum chamber shell is connected with the covering board in a sealed mode. The TEC is arranged on the side face of the vacuum chamber base, the heat sink is arranged on the refrigeration face of the TEC, the vacuum chamber shell is provided with a ventilation hole and an electric control conversion terminal, the ventilation hole is used for vacuum pumping, and the electric control conversion terminal is used for being connected with the TEC; the outer side face of the vacuum chamber base is provided with a water inlet hole and a water outlet hole, and a water channel communicated with the water inlet hole and the water outlet hole is arranged inside the vacuum chamber base. After the structure is adopted, heat produced by the sheet-shaped laser gain media is taken away by circulation cooling water flowing through the vacuum chamber base, therefore, work temperature of the sheet-shaped laser gain media can be accurately controlled, and meanwhile condensation water on surfaces of the sheet-shaped laser gain media is prevented.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

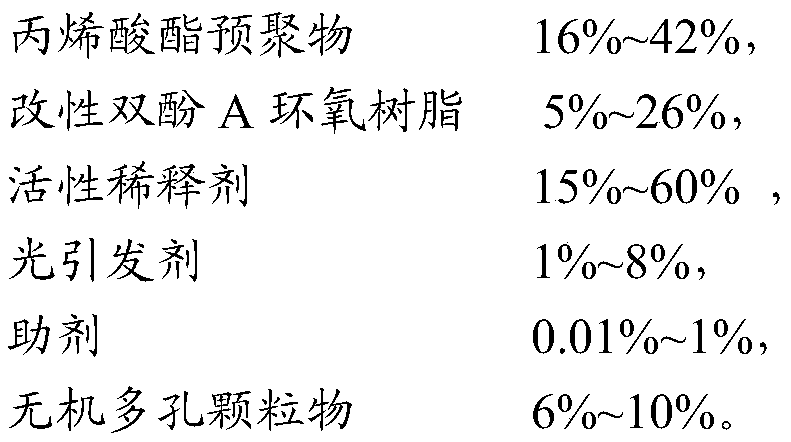

UV glue for package and preparation method thereof

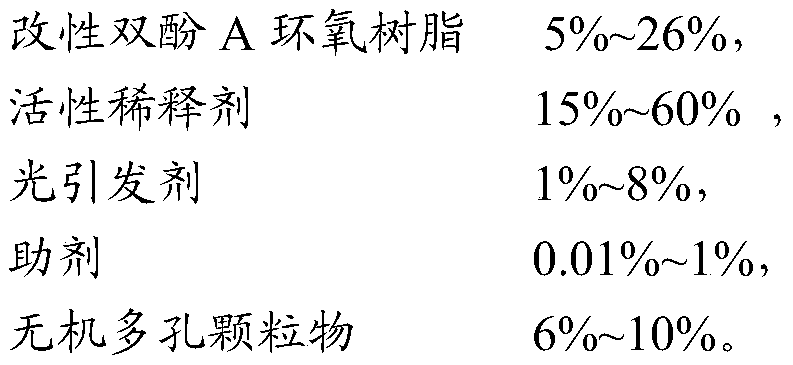

InactiveCN110408350AStrong water vapor adsorption capacityStrong oxygen adsorption functionNon-macromolecular adhesive additivesEster polymer adhesivesParticulatesPolymer science

The invention relates to the field of display technology, in particular to UV glue for package and a preparation method thereof. The UV glue for package is prepared from an acrylic ester prepolymer, modified bisphenol-A epoxy resin, a reactive diluent, a photoinitiator, an addition agent, and inorganic porous particulate matter.

Owner:合肥派森新材料技术有限公司

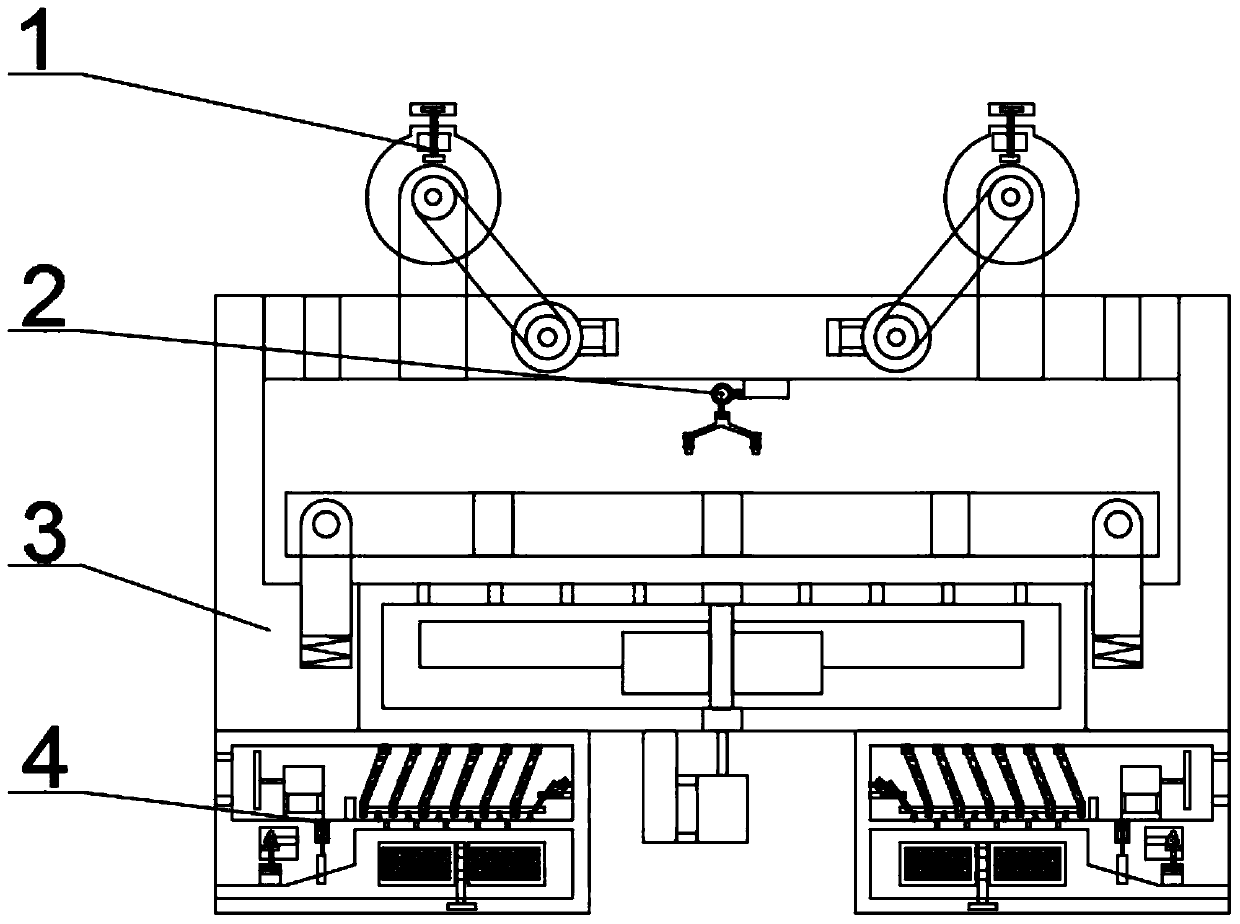

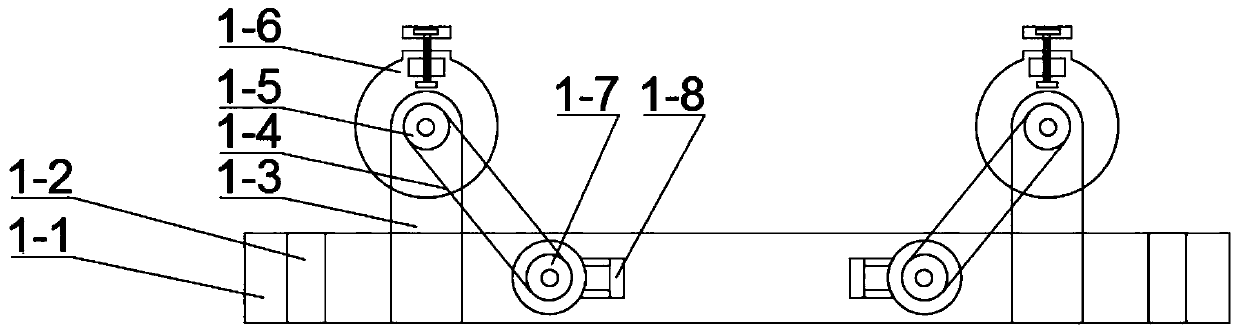

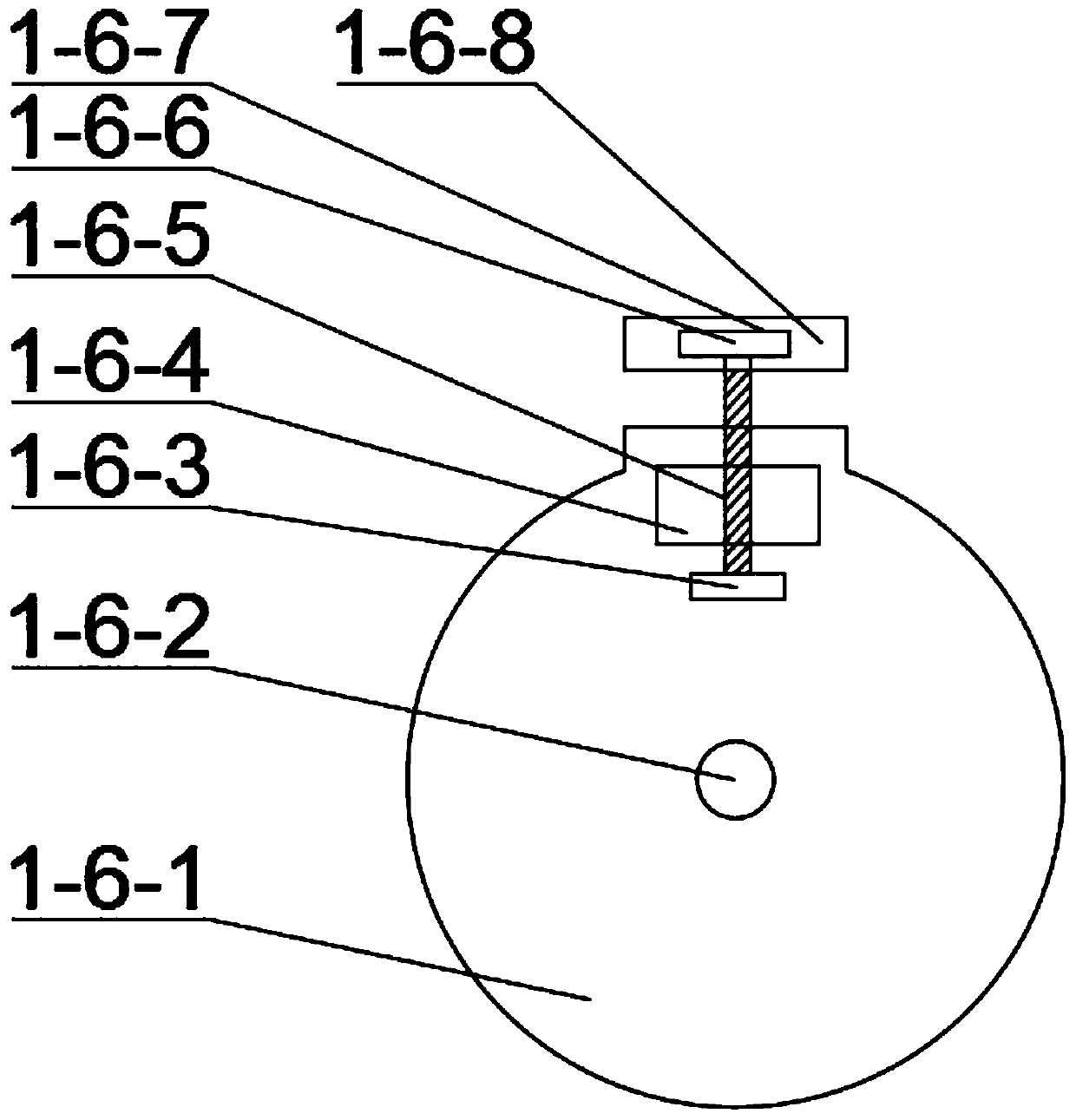

Drying treatment device for spinning

InactiveCN110220372AEvenly heatedAvoid cloggingDrying gas arrangementsDrying machines with progressive movementsWater vaporSludge

The invention relates to a drying device, in particular to a drying treatment device for spinning. A fabric clamping mechanism, a shaking mechanism, a drying mechanism and a dehumidifying mechanism are included; the device can be used for clamping fabric, can be used for drying the fabric, and can be used for shaking the fabric so that the fabric can be heated uniformly; the device can be used forreducing water vapor in air; the device can be used for performing filtering treatment on recycled water, and can be used for preventing sludge from blocking drainage; the shaking mechanism is located below the fabric clamping mechanism which is connected with the drying mechanism; and the dehumidifying mechanism is located below the drying mechanism.

Owner:刘国军

High precision temperature instrument signal detection device

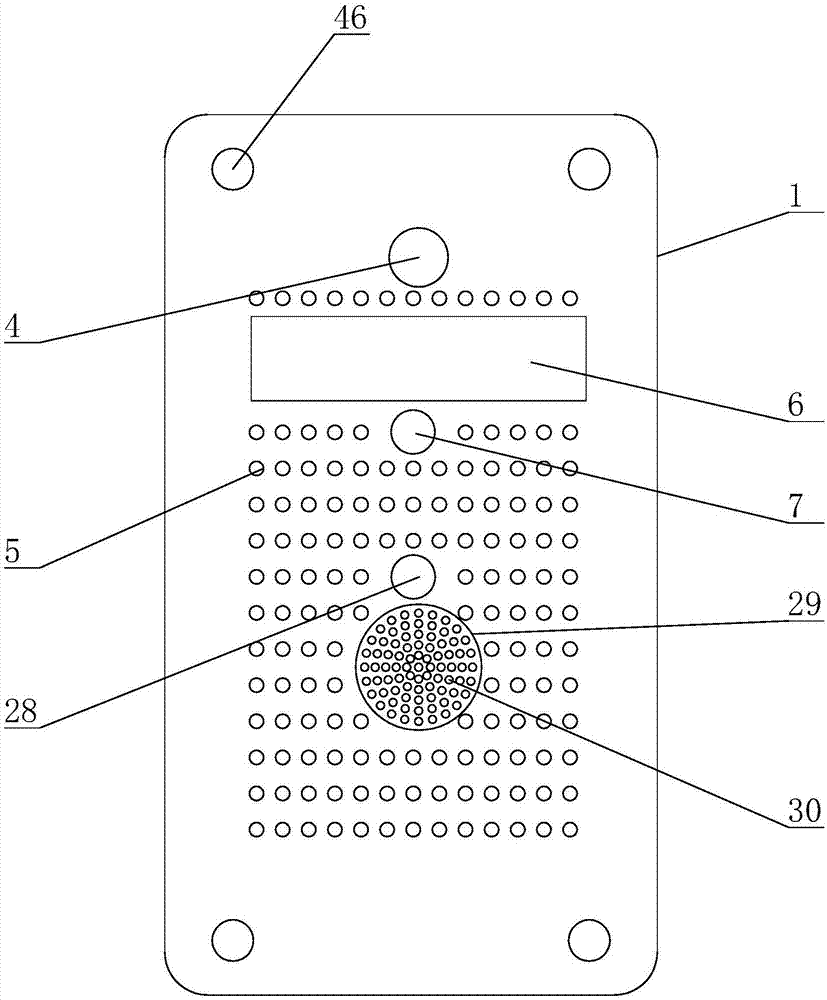

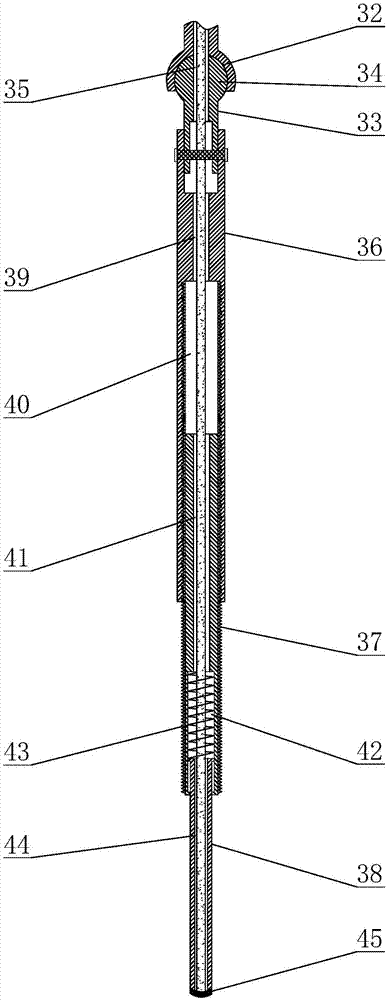

InactiveCN107356352AProtection securityData signal is stableThermometer detailsThermometer with A/D convertersTransformerData signal

The invention discloses a high precision temperature instrument signal detection device and relates to the field of a real-time temperature monitoring device. The detection device comprises an outer board, an inner casing and a temperature monitoring computer system, wherein the inner casing is internally provided with a 220V power source wire, a rectifier, a storage cell, a circuit board, an A / D converter, an AT89C51 single-chip microcomputer and an integrated temperature sensor, the integrated temperature sensor comprises a telescoping touch rod and a sensor casing, the sensor casing is connected with the A / D converter, the A / D converter is connected with the AT89C51 single-chip microcomputer, the AT89C51 single-chip microcomputer is connected with a display screen and the temperature monitoring computer system, and the temperature monitoring computer system is connected with the AT89C51 single-chip microcomputer through a signal cable. The detection device is advantaged in that real-time temperature monitoring of remote village transformer station equipment is realized, a wireless signal monitoring mode is replaced, data signal stability and continuity in a monitoring process are realized, accidents can be avoided, and personal safety is protected.

Owner:王冠霖

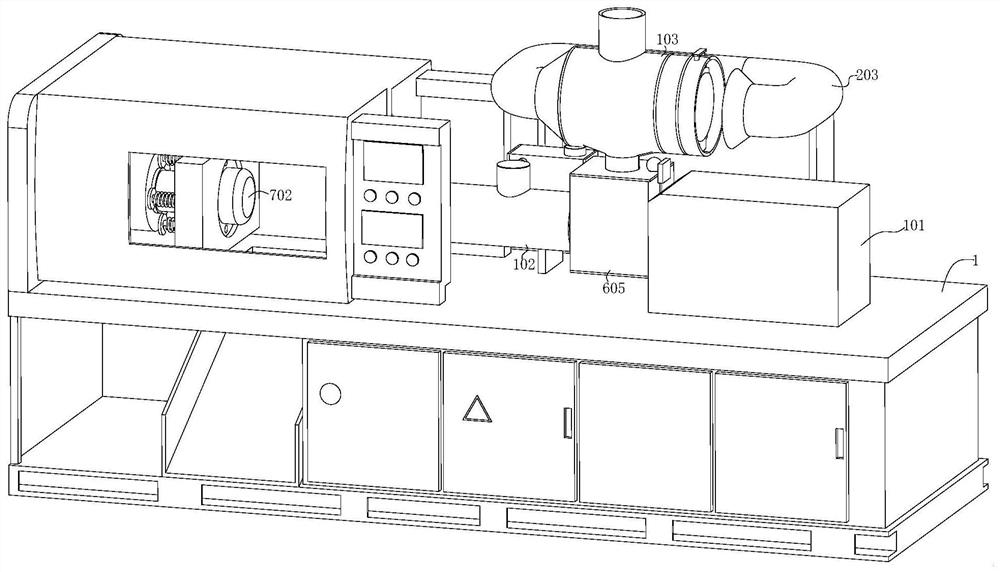

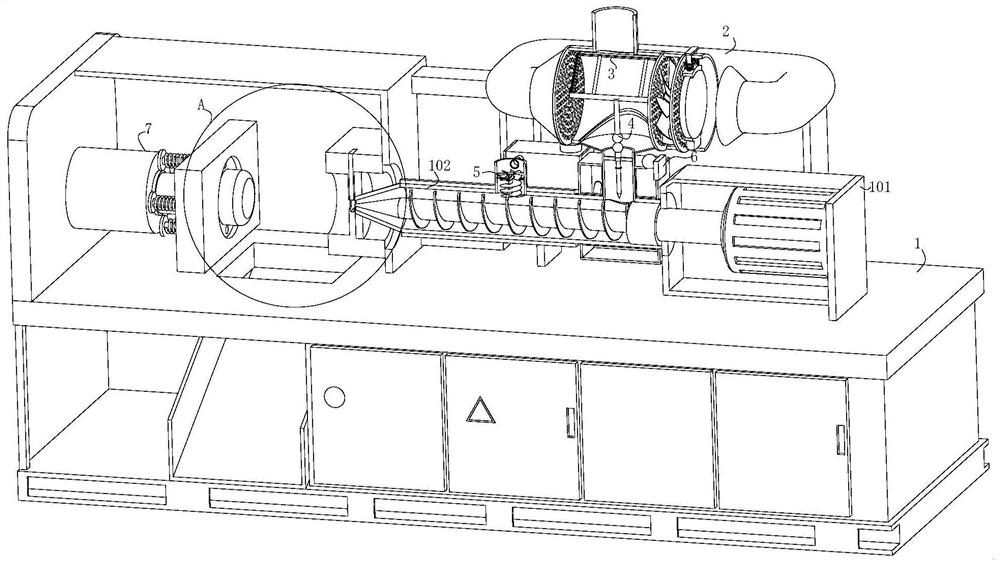

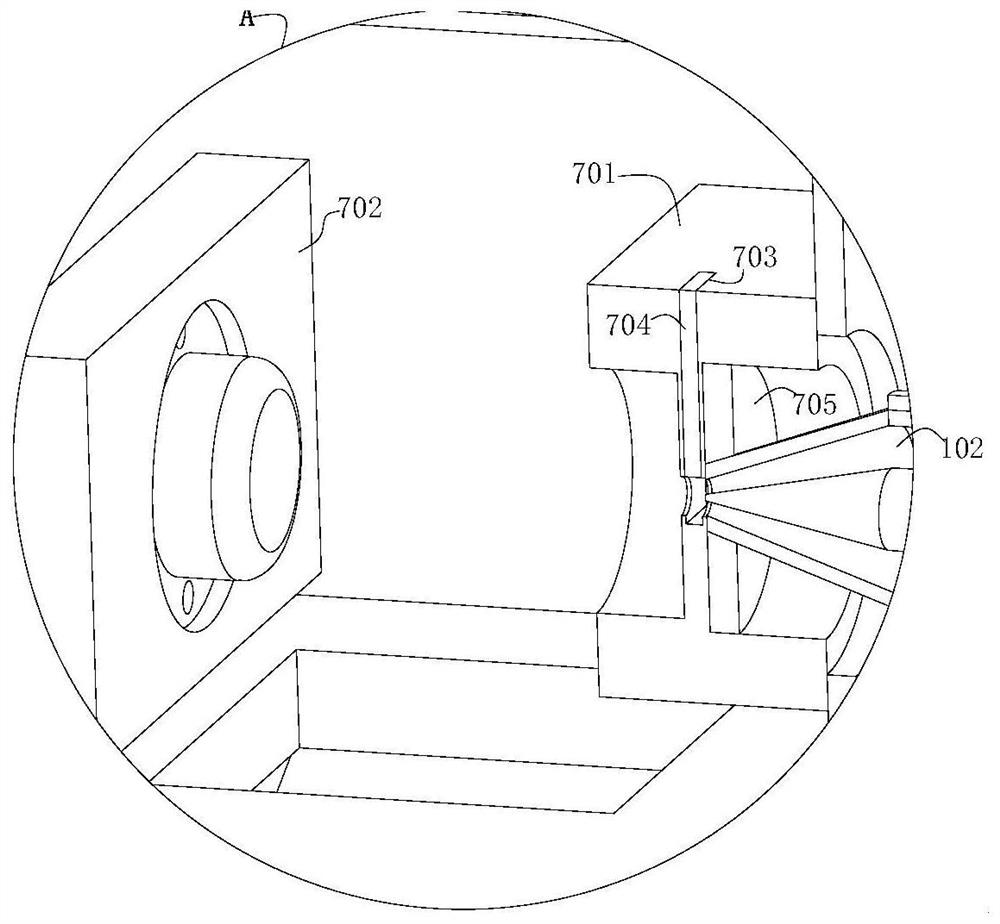

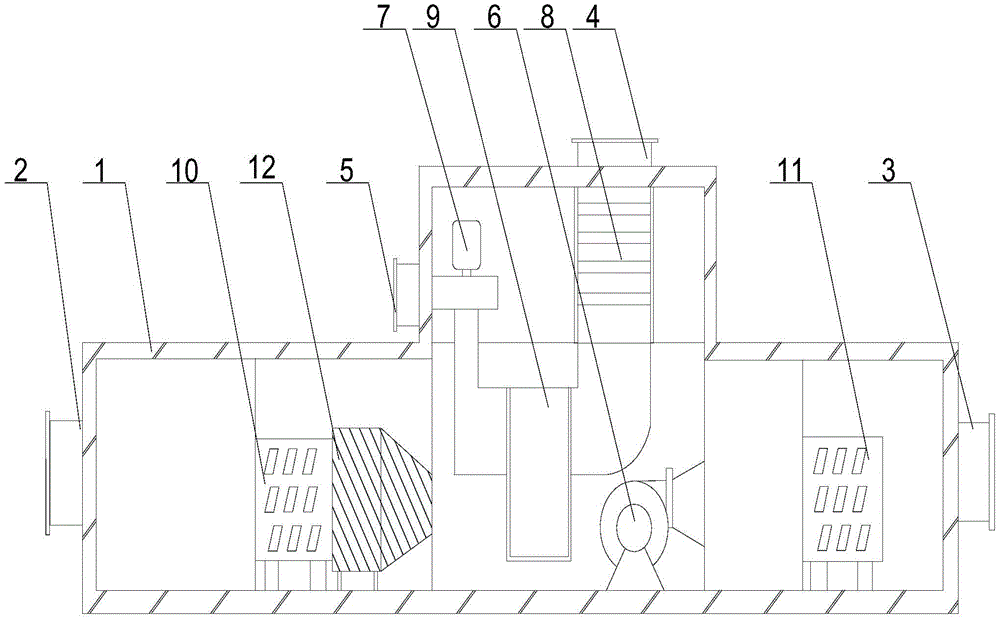

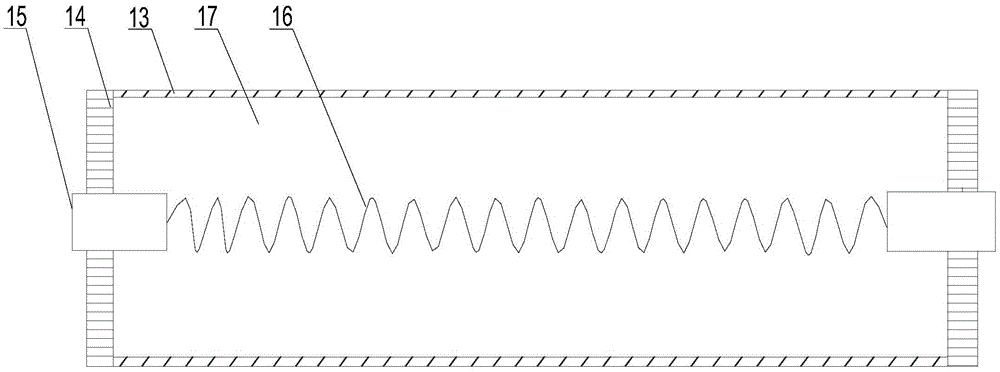

High-efficiency injection molding machine

The invention relates to the technical field of injection molding machines, and specifically relates to a high-efficiency injection molding machine comprising an injection molding machine body. A motor assembly is fixedly installed on the right side of the upper end of the injection molding machine body, an injection molding pipeline is fixedly installed on the left side of the motor assembly, and a first threaded rod movably connected with the motor assembly is rotatably inserted into the injection molding pipeline. A hopper is fixedly arranged at the position, close to one side of the motor assembly, of the upper end of the injection molding pipeline, a drying mechanism is fixedly arranged in the hopper, an exhaust mechanism is fixedly arranged in the middle of the upper end of the injection molding pipeline, and a heating plate is fixedly installed on the left side of the outer wall of the injection molding pipeline. By arranging the drying mechanism, PMMA plastic can be dried during feeding. The dried PMMA plastic can be directly used, drying air can be recycled, loss of the drying plate is reduced, the cost can be effectively reduced, the PMMA plastic injection molding quality is also improved, and the ventilation effect of the drying mechanism can be guaranteed under the cooperation of a cleaning mechanism.

Owner:徐郑

Application method of machine room dehumidifying mechanism

InactiveCN106765698AContinuous and stable dehumidification performanceImprove job stabilityLighting and heating apparatusAir conditioning systemsCold airWater vapor

The invention discloses an application method of a machine room dehumidifying mechanism. The application method comprises the following steps: cold air in an operation room enters a dehumidifying rotating wheel by an intake port; a front cooler performs primary treatment for indoor air, the treated air enters a water stop disc, less water vapor in the air is condensed on the inner wall of the water stop disc, and condensed water drops are discharged into a shell by an annular groove; wet air in the operation room is treated in a treatment area, the dehumidifying rotating wheel is driven to slowly rotate, and the water vapor to be saturated in the treatment area enters a regeneration area; fresh air is injected through a regeneration intake port, and is heated by a heater; and finally, the dried air is exhausted out of the shell to renewedly flow into the operation room.

Owner:重庆靠岸机电设备有限公司

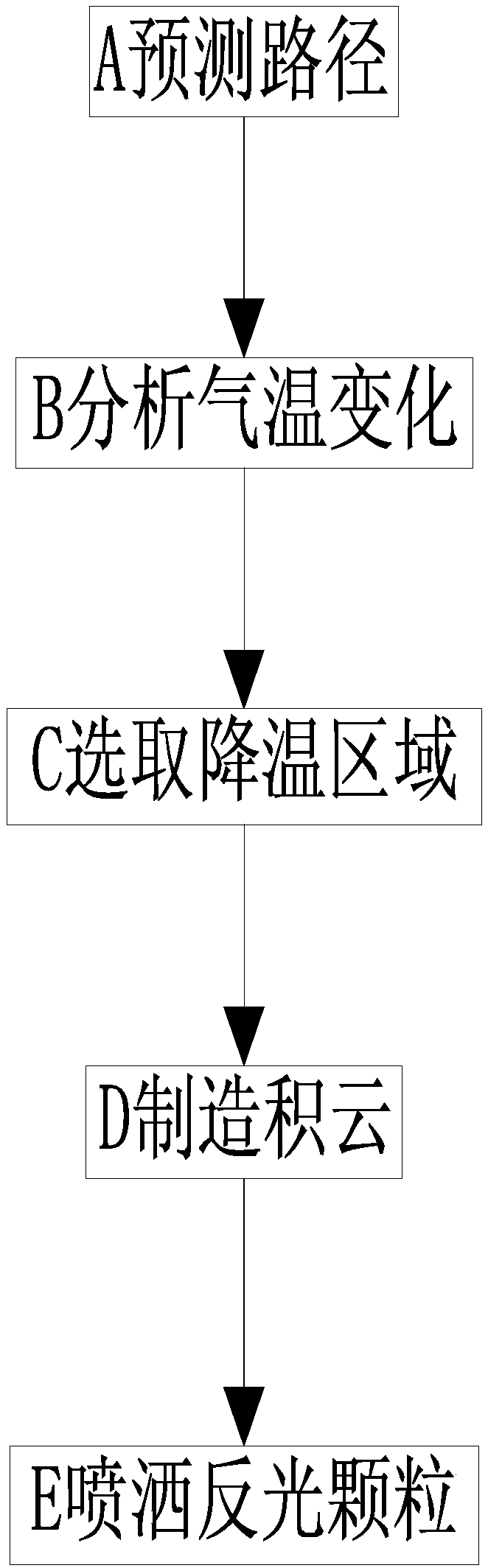

Method for weakening typhoon power

InactiveCN109380042AReduce the presence of moistureSave heatWeather influencing devicesComputer scienceWind force

The invention discloses a method for weakening typhoon power. The method comprises the following steps that typhoon data is analyzed through a satellite, and an estimated path and an estimated landingplace of typhoon are obtained; high-temperature areas of the travel path between the real-time position of the typhoon and the estimated landing place are analyzed through the satellite; at least onearea in the high-temperature areas of the travel path between the real-time position of the typhoon and the estimated landing place is selected as a cooling area; cumulus cloud is manufactured, wherein the artificial cumulus cloud is manufactured above the cooling areas through an aircraft; reflective fine particles are sprayed into the cumulus cloud above the cooling areas through the aircraft.The method has the advantages that by manufacturing the cumulus cloud capable of reflecting sunlight above the sea surface on the travel path of the typhoon, the heat energy of the sea surface is reduced, and the temperature of the sea surface is reduced. The power, the collapsing force and the influence range of the typhoon are weakened, and the damage of the typhoon to people on the landing place and the property of people is avoided.

Owner:中山市博林树投资管理有限公司

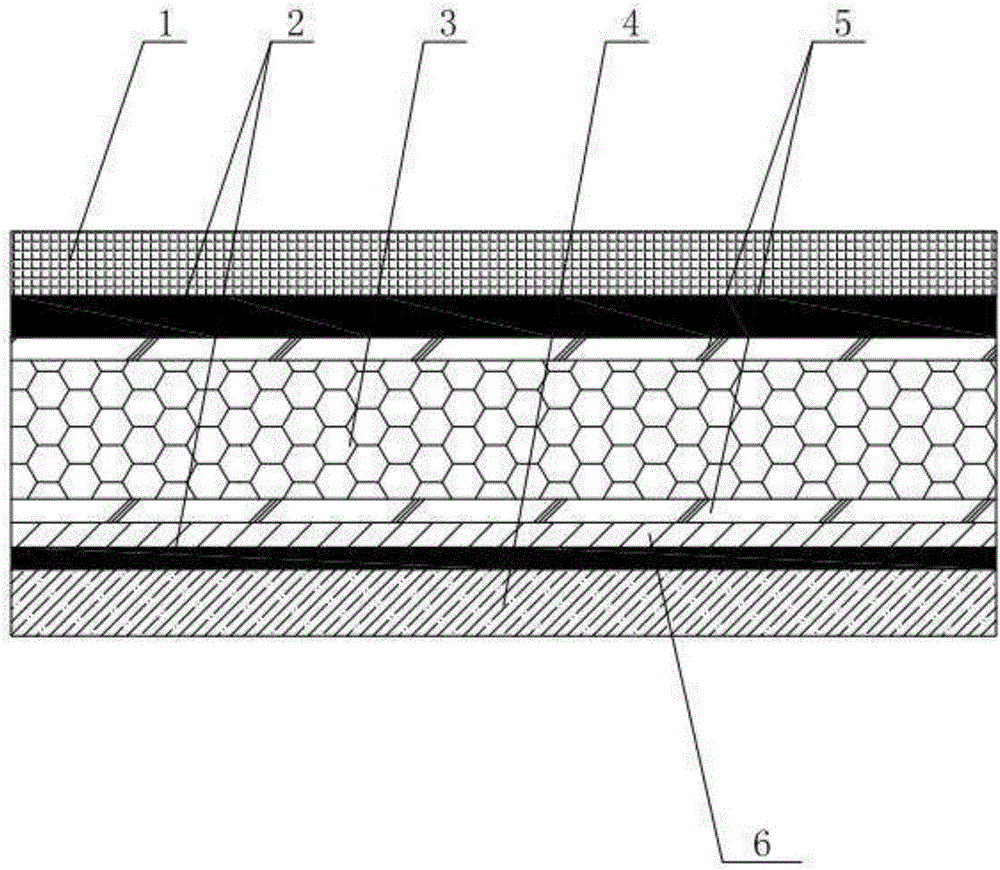

Solar back plate with high barrier property

InactiveCN106218155ALow costGood environmental performanceSynthetic resin layered productsPhotovoltaic energy generationPhysicsReflectivity

The invention relates to a solar back plate with the high barrier property. The solar back plate comprises a polyester film, a high reflection layer and a bonding layer-bonded weather resistance layer are sequentially arranged on one side of the polyester film, and a high reflection layer, barrier layers and a bonding layer-bonded weather resistance bonding layer are sequentially arranged on the other side of the polyester film; the barrier layers comprise the oxygen barrier layer and the vapor barrier layer. The solar cell back plate is obviously superior to an existing back plate, the electrical insulation property and the vapor barrier property are improved by arranging the polyester film, and the solar back plate is high in damp-heat resistance and aging resistance, long in life, high in weather resistance and reflection rate and excellent in aging resistance. By adopting a gelatin material as the oxygen barrier layer and adopting an inorganic material as the vapor barrier layer, the solar back plate is low in cost, the vapor barrier layer and the oxygen barrier layer can barrier vapor and oxygen respectively, the barrier property of the back plate is promoted, and the vapor and oxygen transmission rate of the solar back plate is obviously decreased.

Owner:WUXI SUNOCEAN

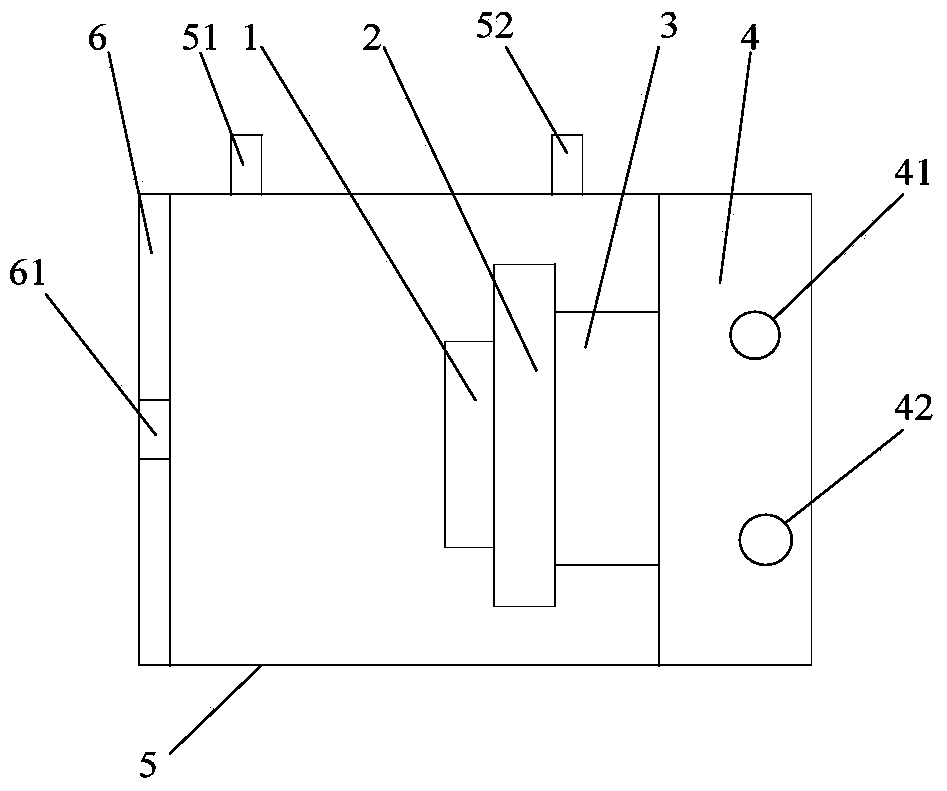

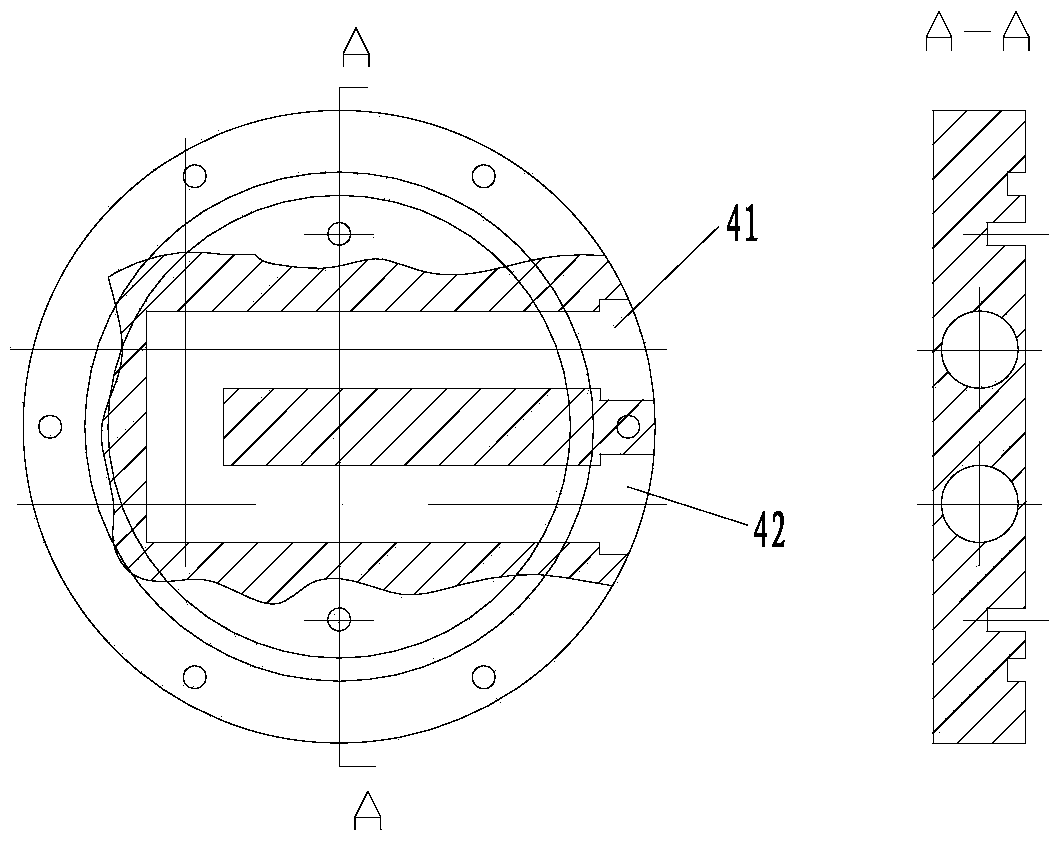

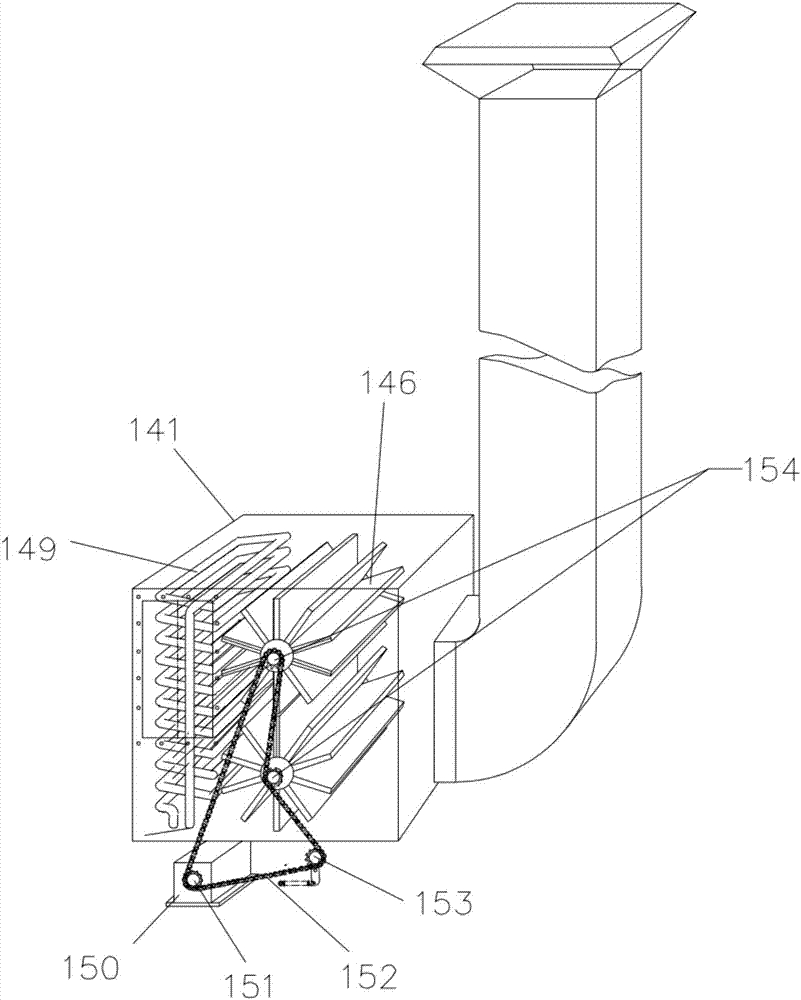

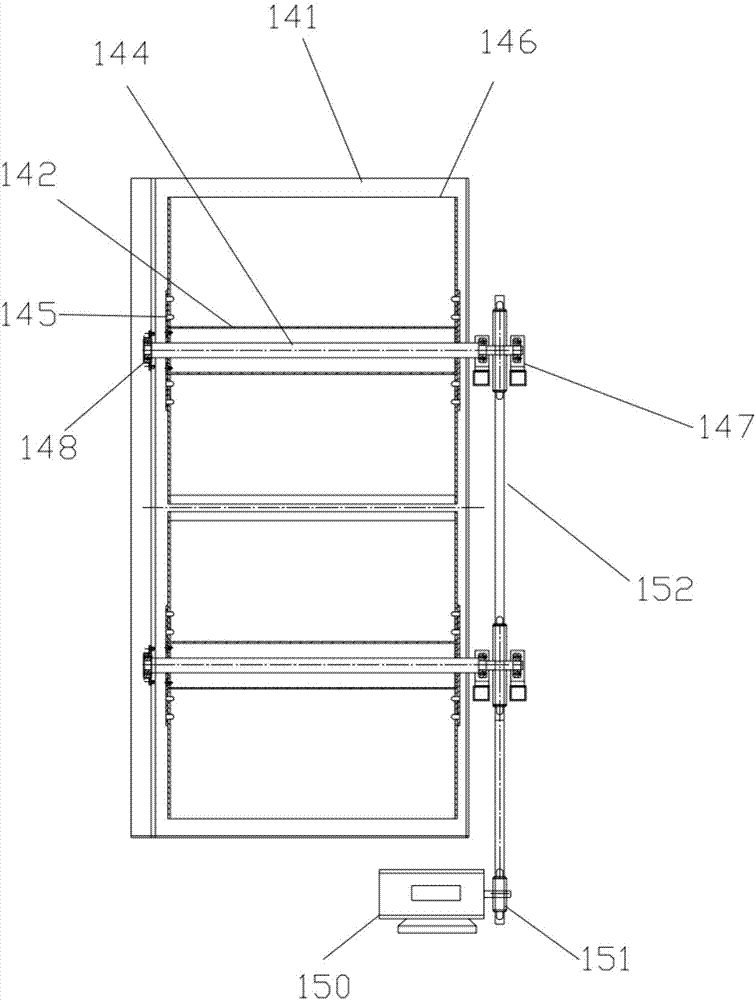

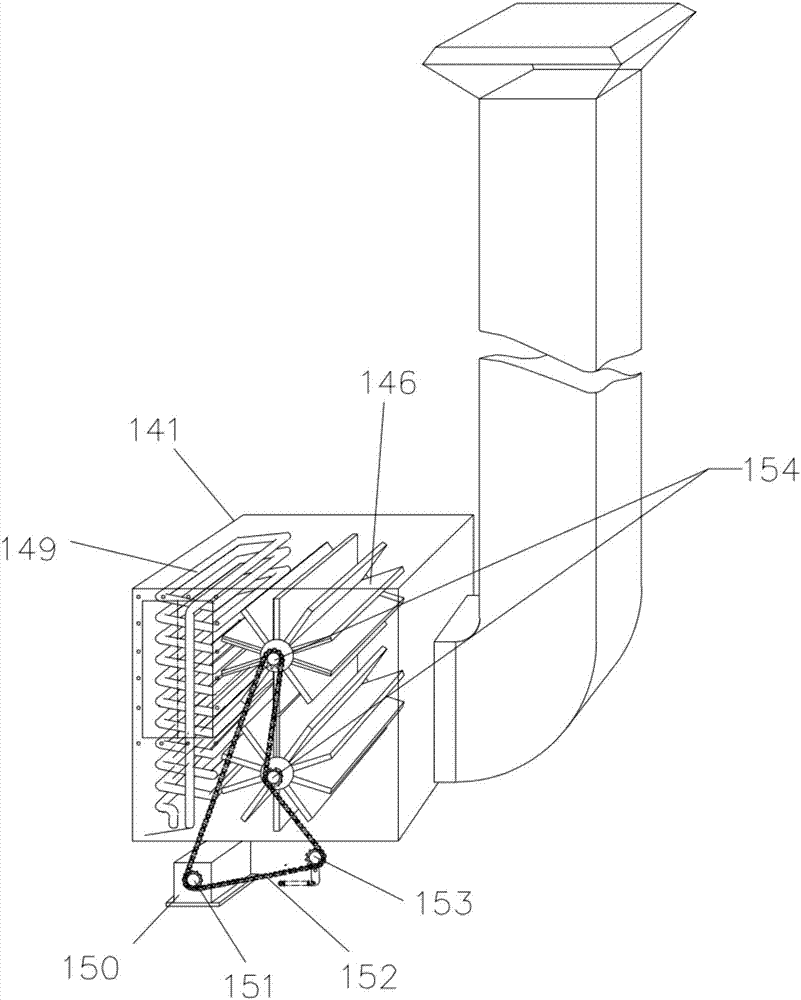

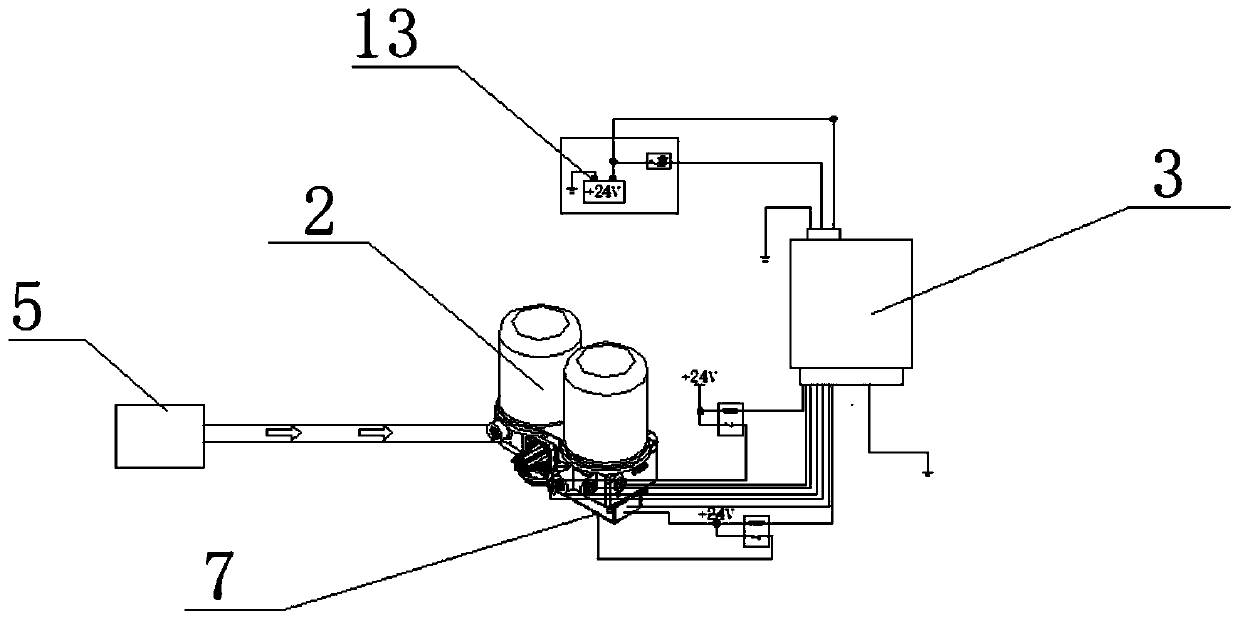

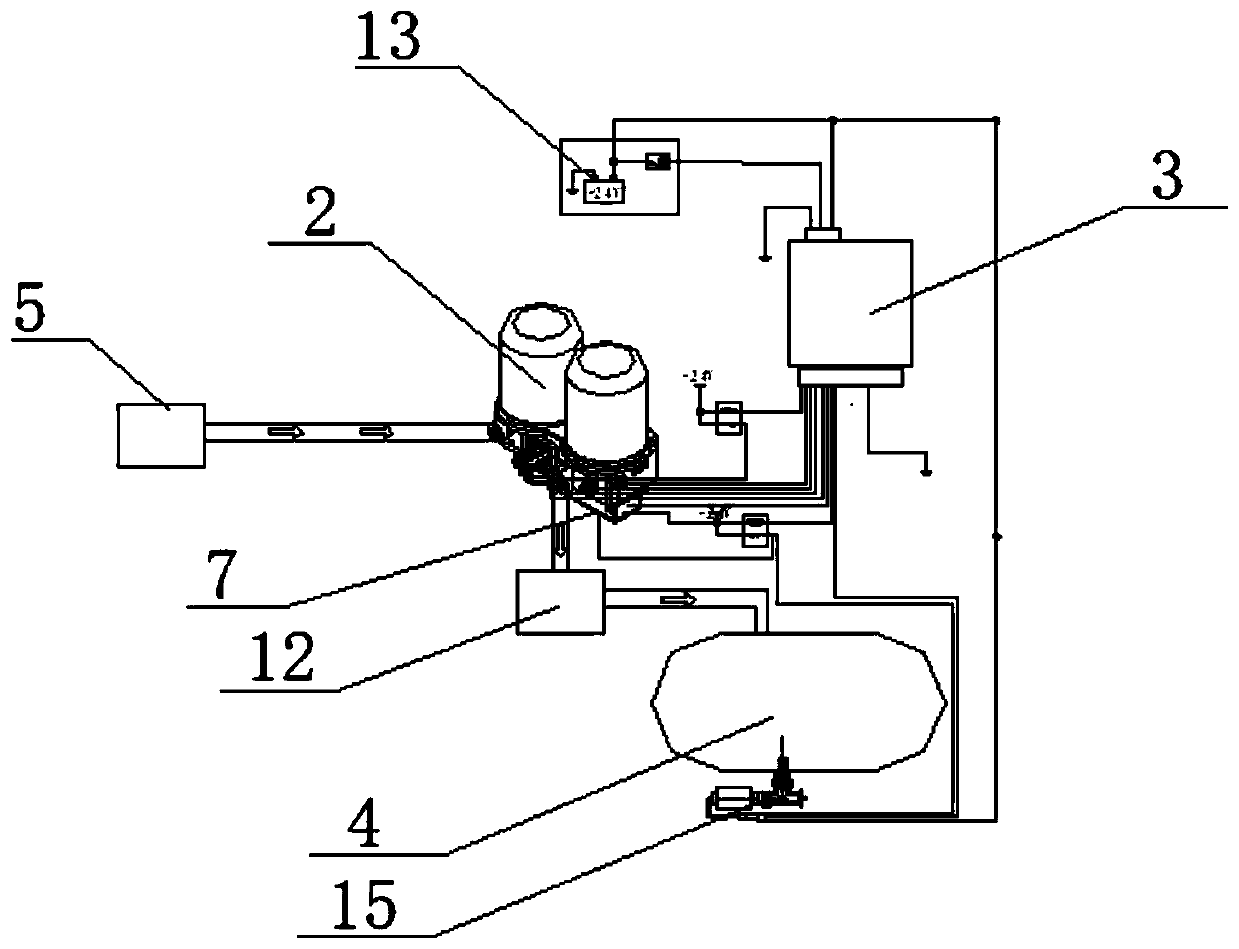

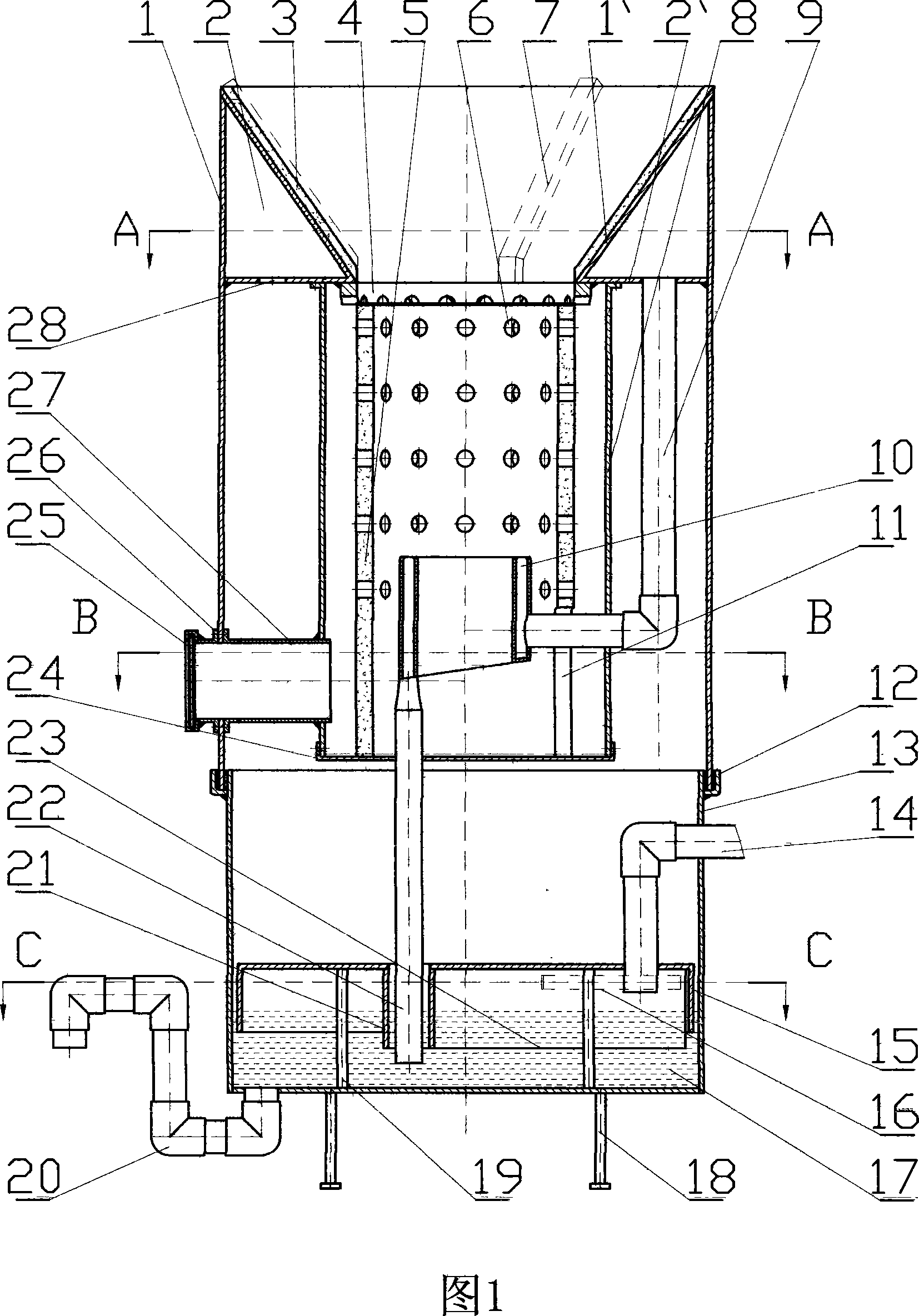

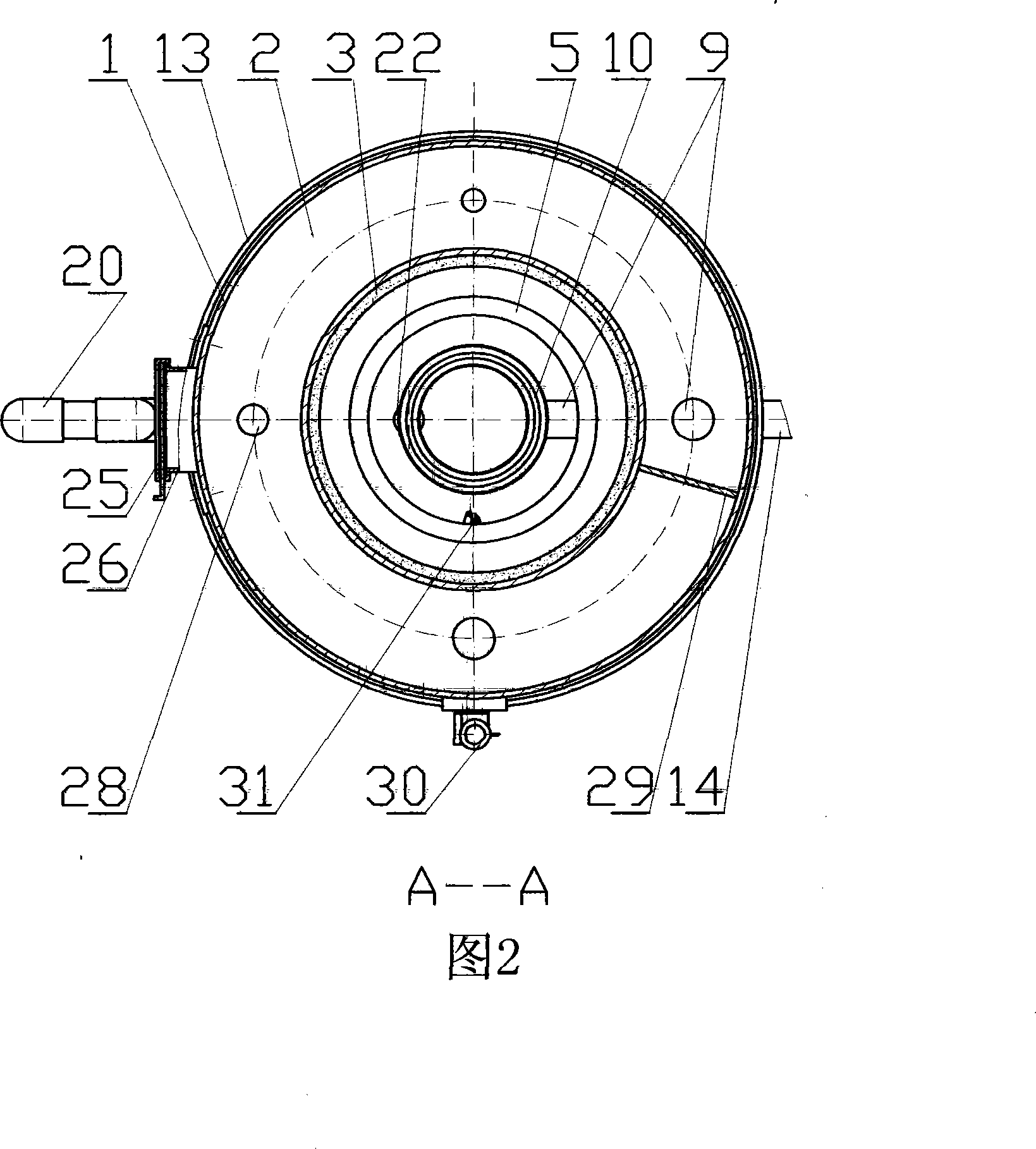

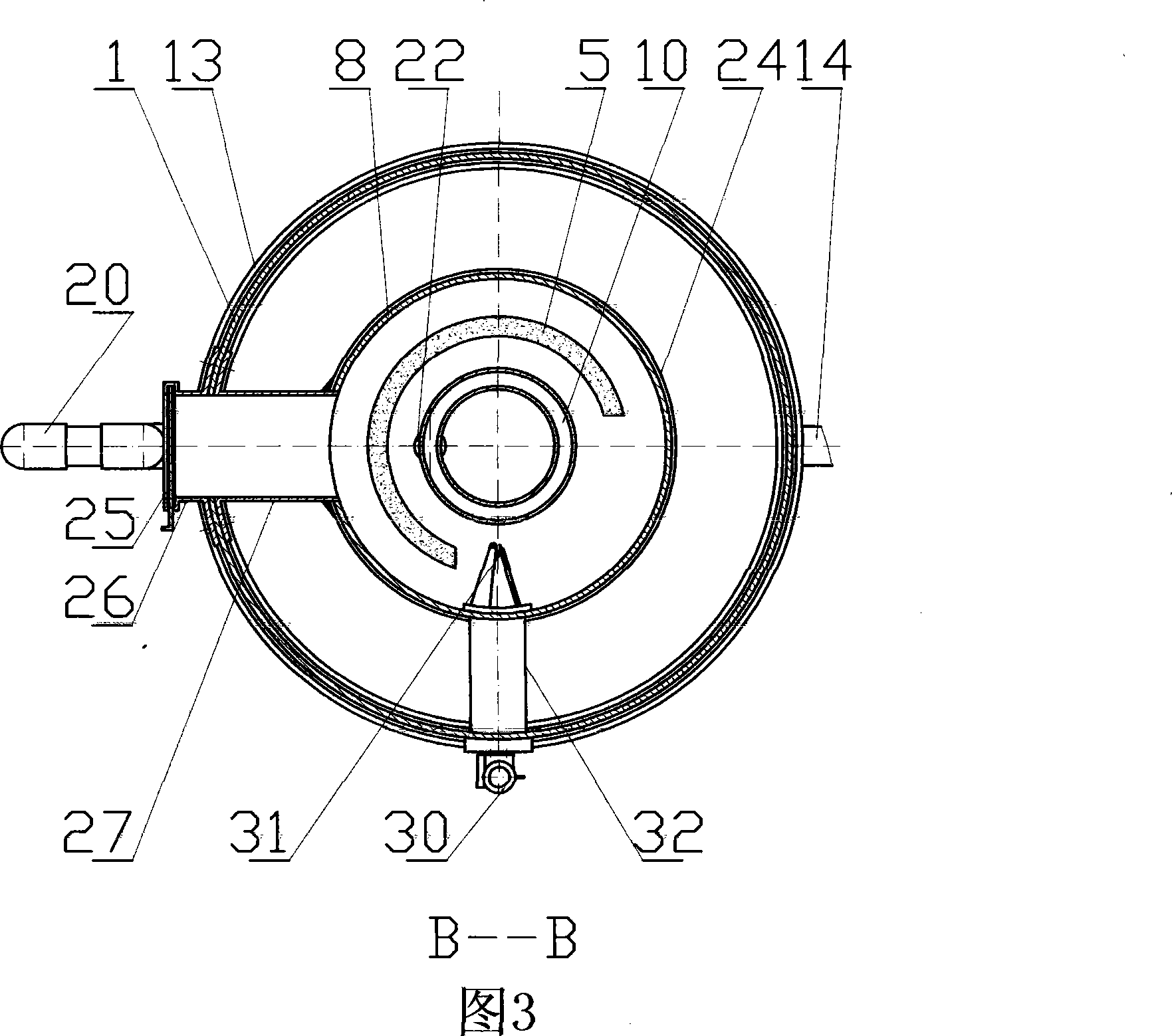

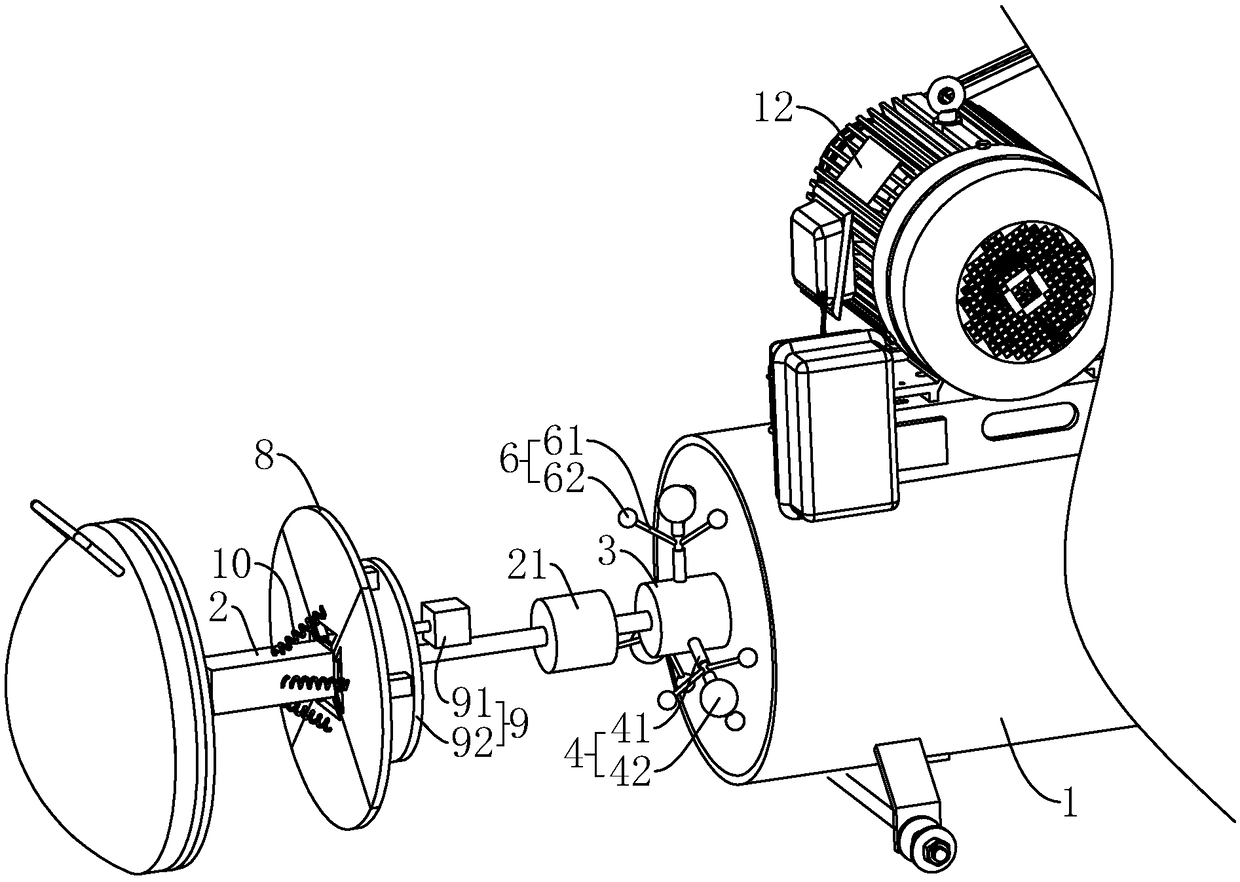

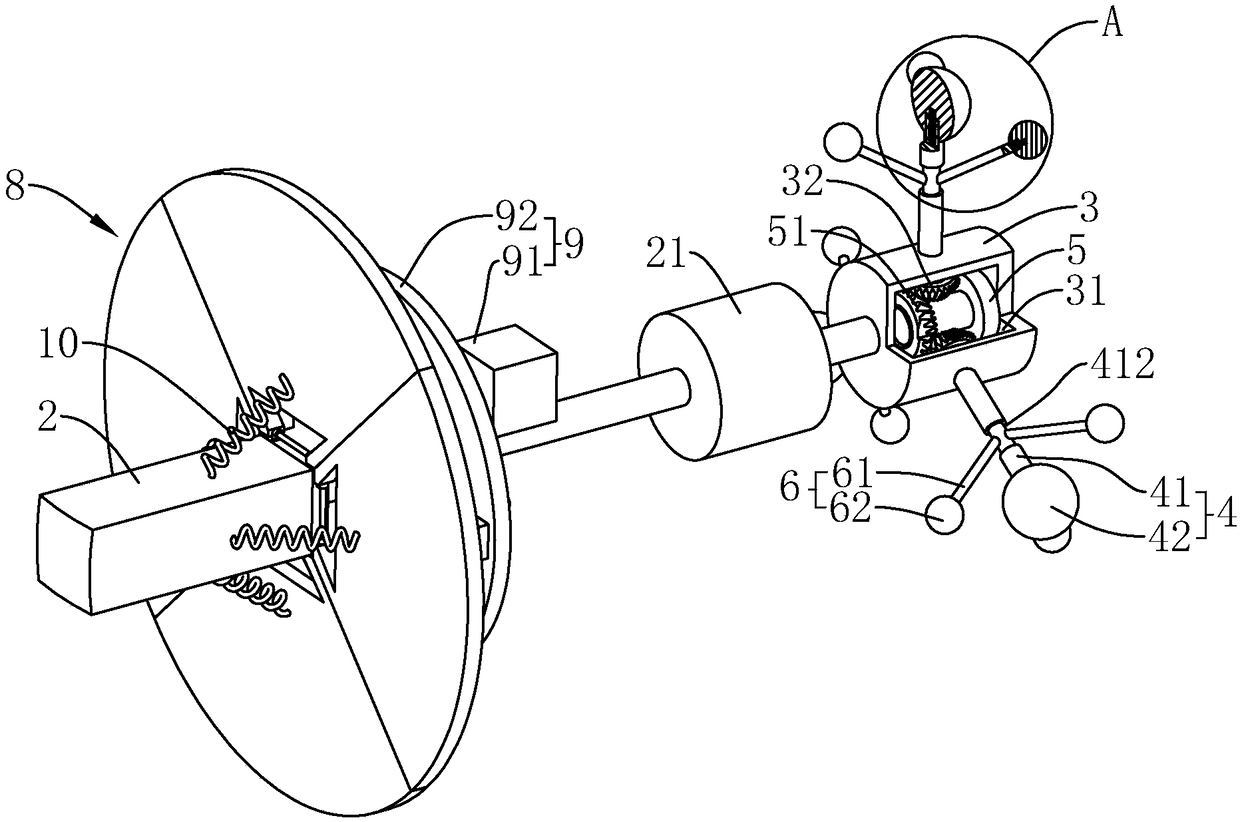

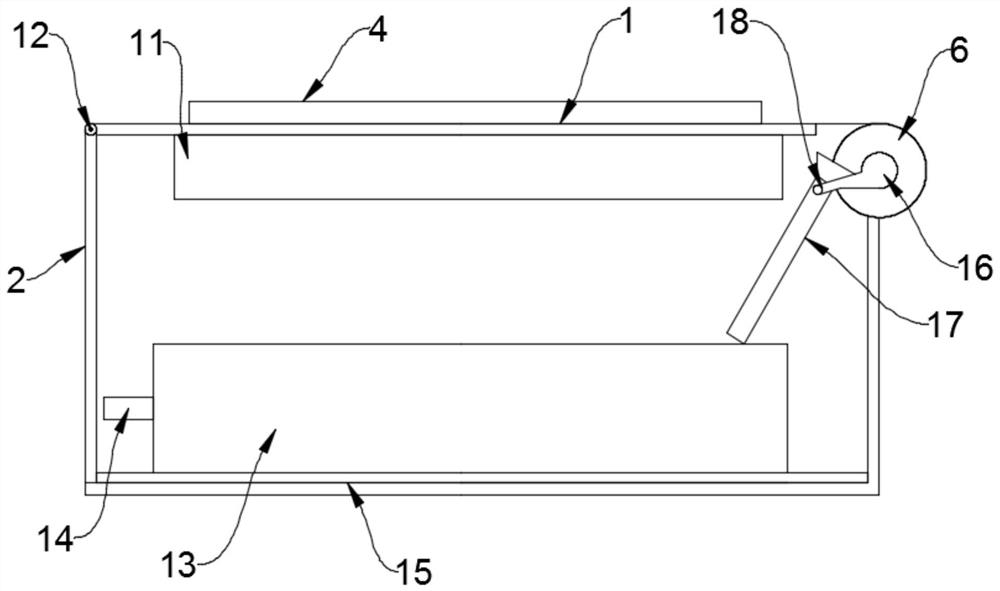

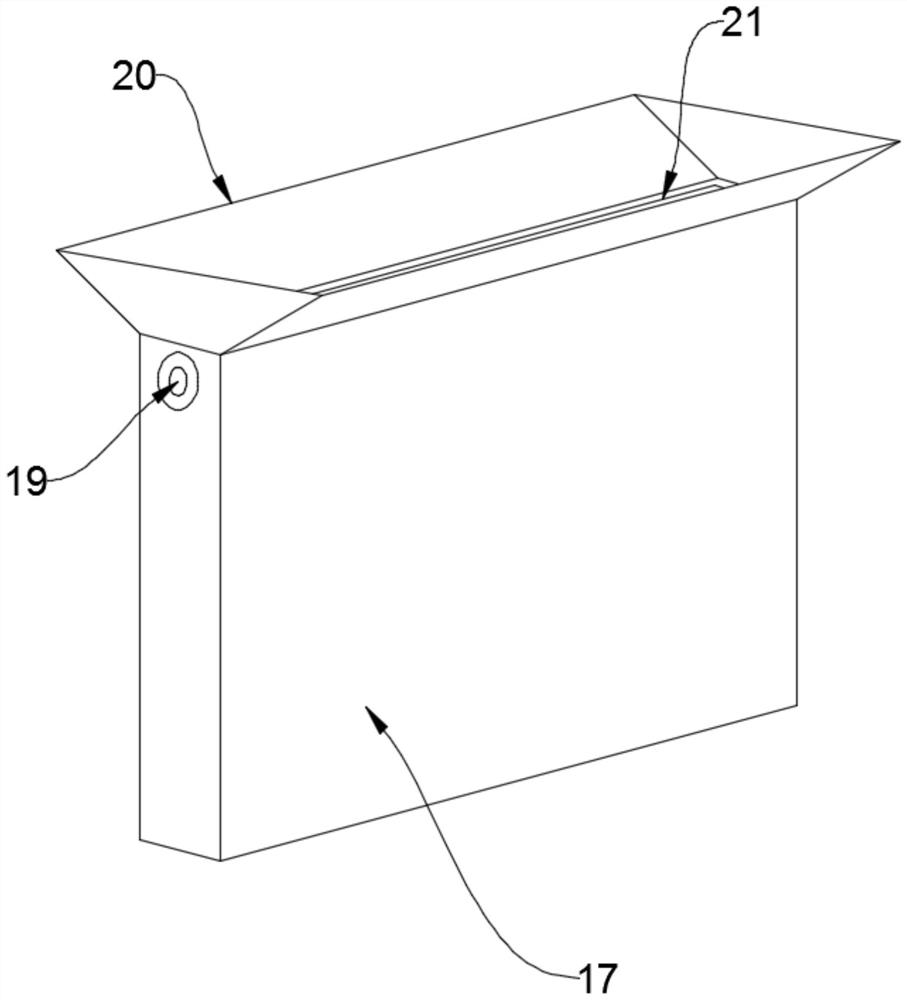

Rotational activated carbon adsorption tank and cooking fume purifier

ActiveCN107970696AIncrease the adsorption areaReduce the presence of moistureGas treatmentDispersed particle filtrationActivated carbonEngineering

The invention discloses a rotational activated carbon adsorption tank which comprises a tank body, a rotational activated carbon adsorber, a heater and a chain driving system, wherein the rotational activated carbon adsorber is mounted inside the tank body and is used for implementing adsorption purification treatment on micro particles in cooking fume; the heater is mounted inside the tank body and is used for reducing steam of the rotational activated carbon adsorber; the chain driving system is arranged outside the tank body; and the chain driving system is connected with the rotational activated carbon adsorber to drive the rotational activated carbon adsorber to rotate along with the chain driving system. Micro particles in cooking fume are removed through the rotational activated carbon adsorber. In the removal process, the purposes that in a relatively small equipment space, an activated carbon adsorption area is increased by times, activated carbon particles are driven to moveup and down along with rotation of the rotational activated carbon adsorber, caking of the activated carbon particles is alleviated, and the adsorption effect is improved, are achieved.

Owner:BEIJING SHENGLINFENG ADVERTISING DESIGN & MAKING CO LTD

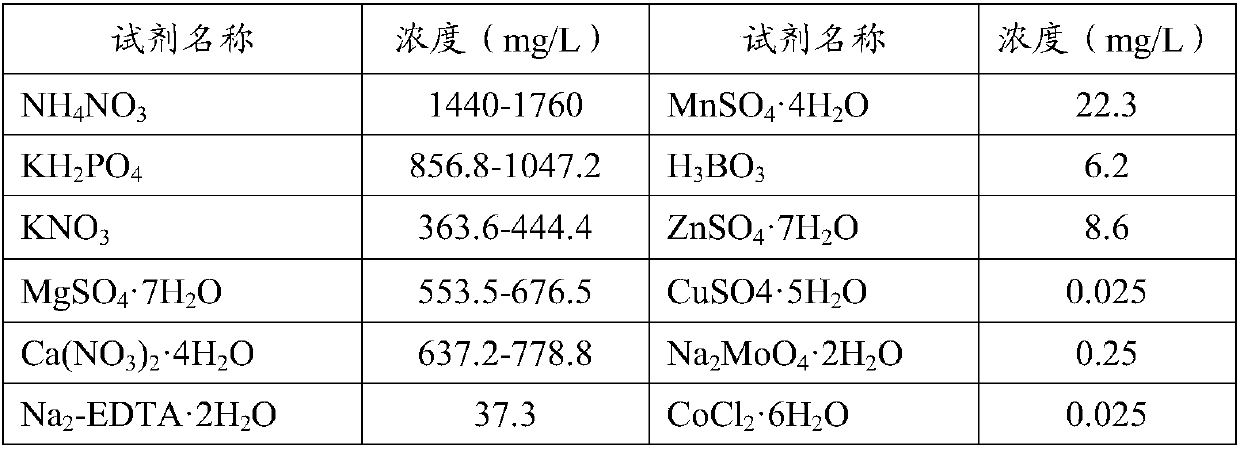

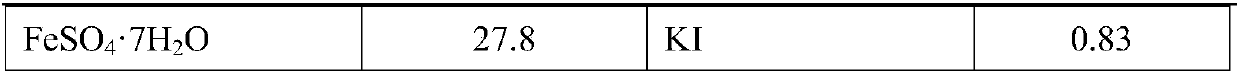

Aerial fog cultivation nutrient solution for breeder's seed of virus-free potato and application method of serial fog cultivation nutrient solution

PendingCN107721517AReduce salt concentrationReduce mortalityMagnesium fertilisersAlkali orthophosphate fertiliserNutrientPhases of clinical research

The invention discloses an aerial fog cultivation nutrient solution for a breeder's seed of a virus-free potato and an application method of the serial fog cultivation nutrient solution. The aerial fog cultivation nutrient solution mainly contains five nutrient solutions: an HR nutrient solution, an HG nutrient solution, an HF nutrient solution, an HE nutrient solution and an HH nutrient solution;the whole aerial fog cultivation process of test-tube seedlings of the virus-free potato is divided into five stages: a rooting stage, a seedling stage, a tuber formation stage, a tuber expansion stage and a harvesting stage; and different nutrient solution formulae are respectively set in different stage, and the nutrient solutions are sprayed according to different atomizing periods. The aerialfog cultivation nutrient solution has the advantages that the survival rate of the test-tube seedlings of the virus-free potato is remarkably increased, the growth of fog-cultivated plants of the potato is effectively promoted, the fog-cultivated fruiting number is increased, the single grain weight is increased, and the storage rotting rate of the fog-cultivated potato blocks is decreased.

Owner:达州市农业科学研究院

Dryer for paper

InactiveCN106895694AReduce the presence of moistureImprove ventilationDrying gas arrangementsDrying solid materialsEconomic benefitsPulp and paper industry

The invention discloses a drying machine for paper, which comprises a base, an organic body is arranged on the top of the base, an alarm light is fixedly connected to one side of the body, an exhaust fan is arranged on the other side of the body, and one side of the exhaust fan runs through the body On the other side of the machine body, the top of the body is provided with a sealing cover, the bottom of the sealing cover is provided with a baking plate, and a support rod is provided directly below the baking plate, and the inner bottom wall of the body is fixedly connected with a relatively first telescopic rod. One side of each of the first telescopic rods is provided with a second telescopic rod, and the bottoms of the two second telescopic rods are fixedly connected with the inner bottom wall of the body. The dryer for paper enables the paper to hang vertically inside the machine body, so that the paper can absorb heat evenly, so that it can be dried quickly, improve work efficiency, and ensure the ventilation inside the machine body to avoid airtightness caused by the airtight seal of the machine body. The internal temperature rises to avoid fires, ensure the safety of workers, and improve the overall economic benefits.

Owner:博艳萍

Intelligent gas circuit management system and control method thereof

ActiveCN110920592APrevent freezingImprove filtering effectAir treatment devicesBrake safety systemsAir filterEngineering

The invention discloses an intelligent gas circuit management system and a control method thereof. The air path management system comprises a dryer device provided with a heater, an ECU control module, an air cylinder, an air compressor and at least two intelligent drain valves. A heating module is arranged in the intelligent drain valve; the control method comprises the following steps: when theECU control module receives working signals of the air compressor, the temperature and humidity sensor, the air pressure sensor and the environment temperature sensor; the ECU analyzes, judges and outputs an execution instruction through a built-in program; the heater, the first intelligent drain valve and the second intelligent drain valve are respectively controlled to work; meanwhile, abnormalsignals are analyzed, judged and output for alarming. According to the invention, the problems that the existing universal technology and related parts have poor air filtering and purifying effects onthe interior of the vehicle air pipeline and cannot meet the use conditions of severe weather and many regions are solved, the related potential safety hazards can be eradicated, and the intelligentlevel and the safety of the vehicle are improved to a higher level.

Owner:扬州市奥特瑞汽车电子科技有限公司

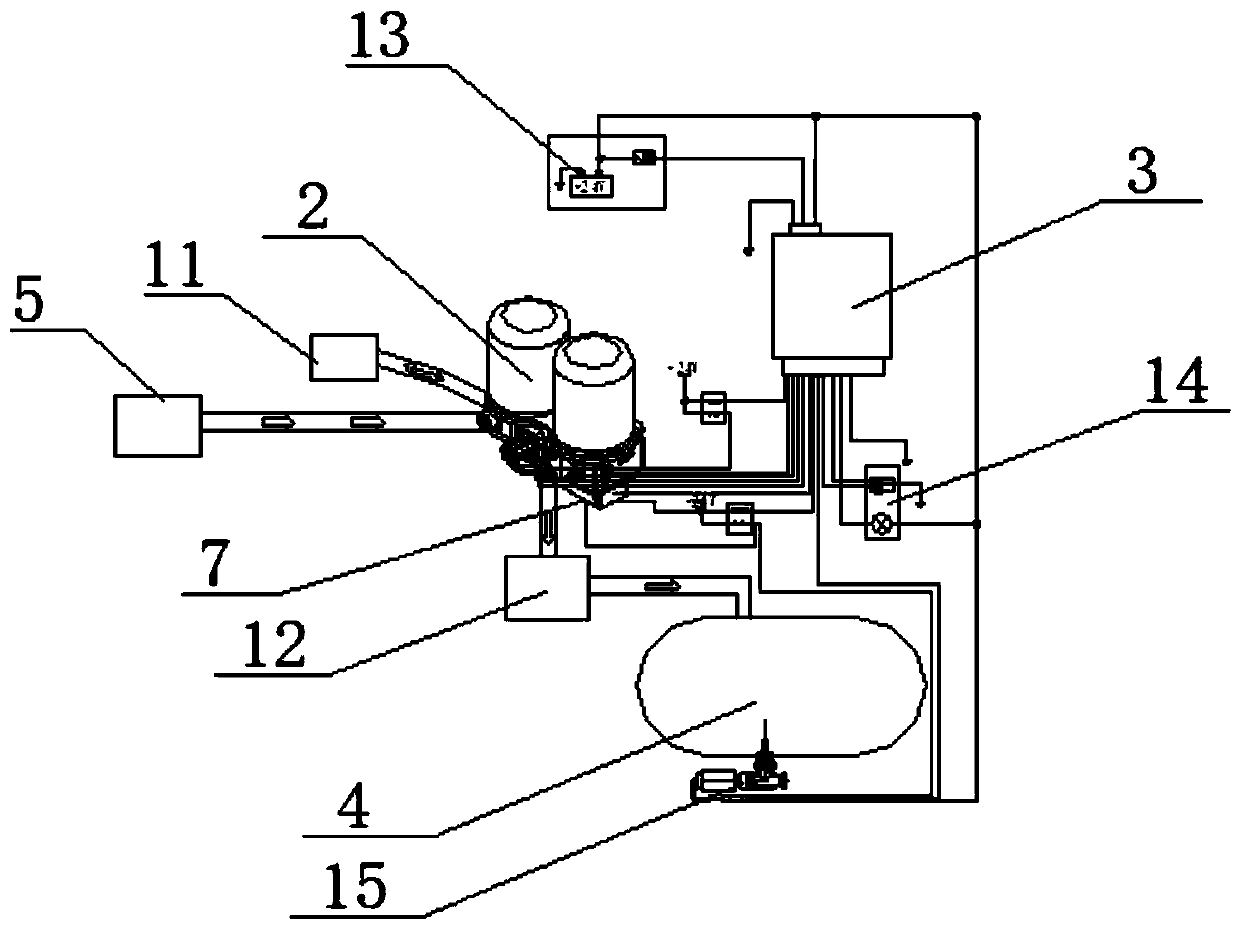

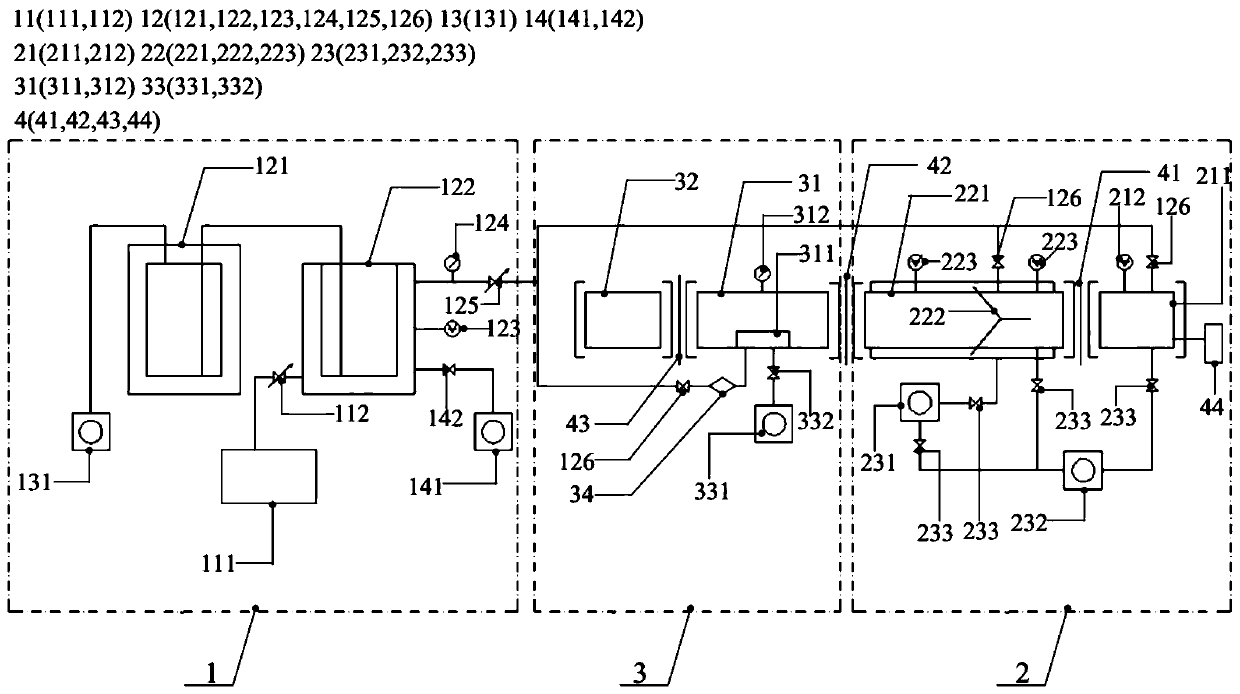

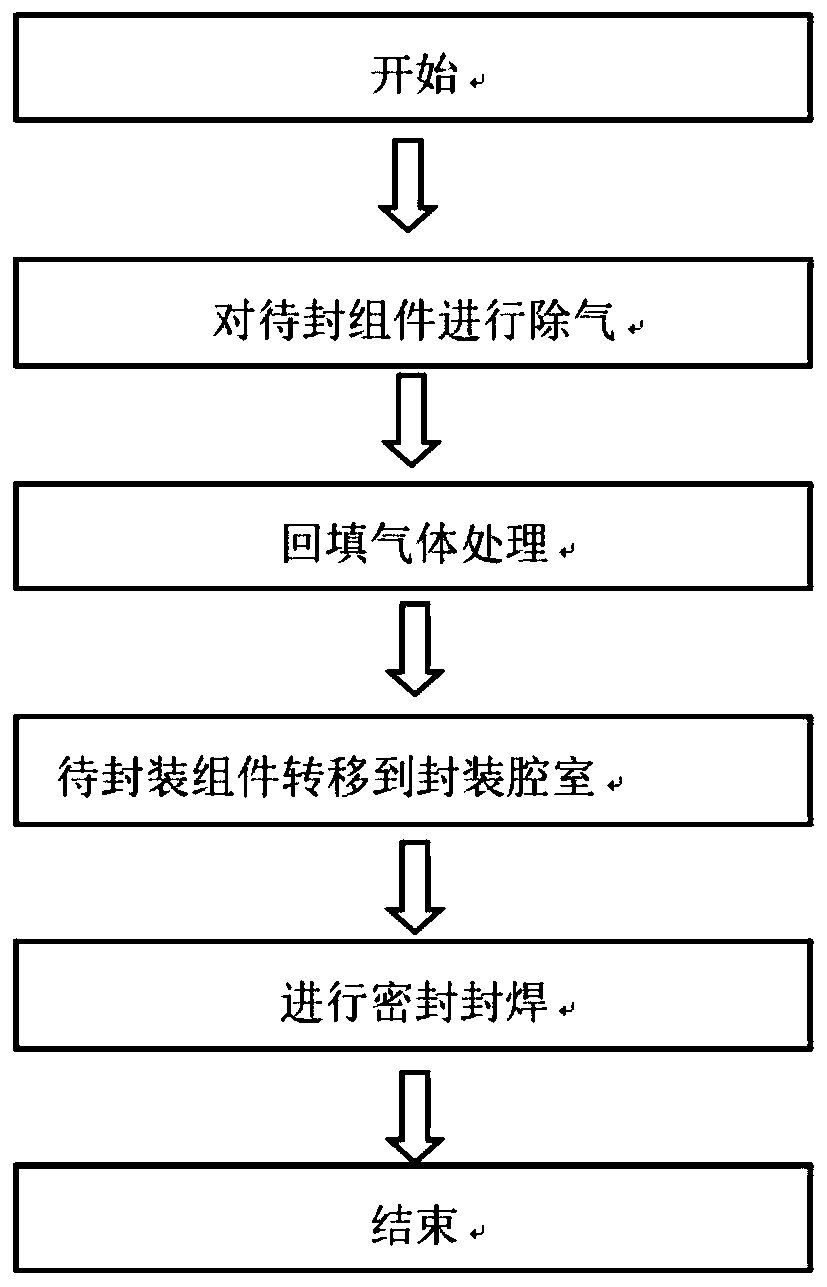

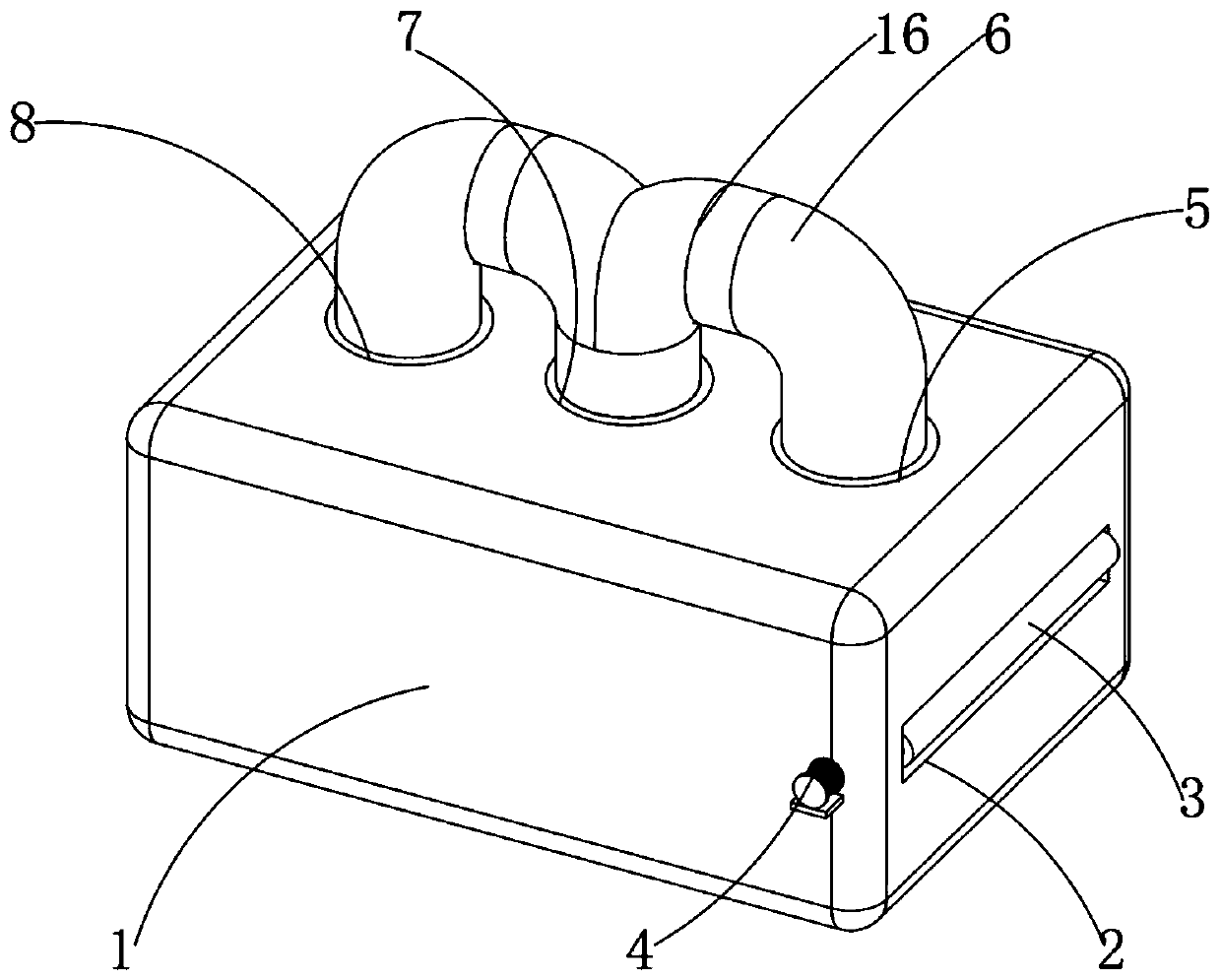

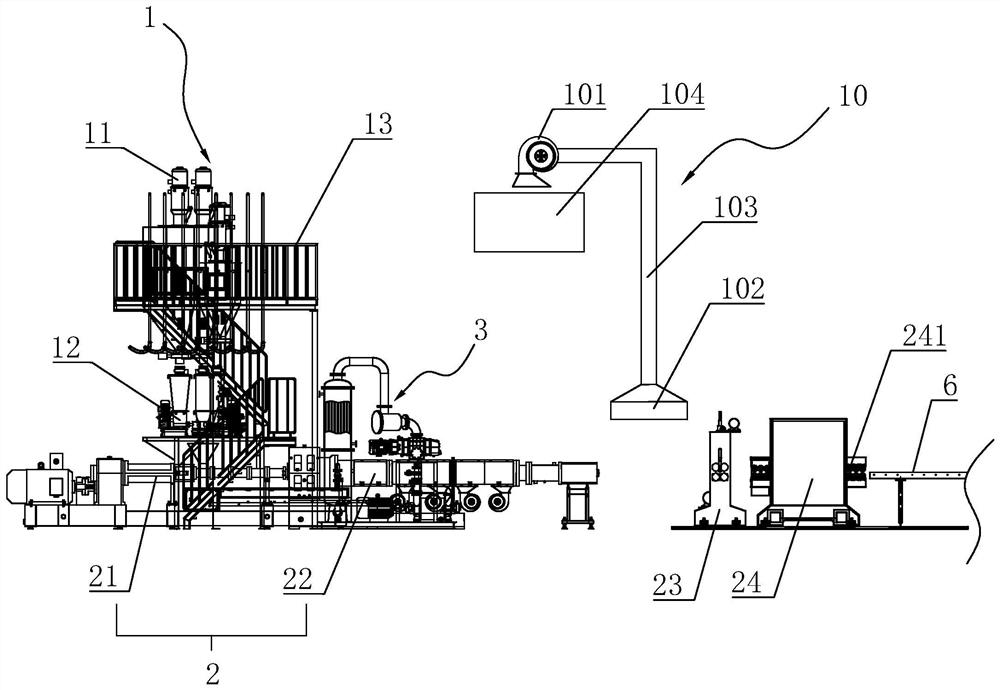

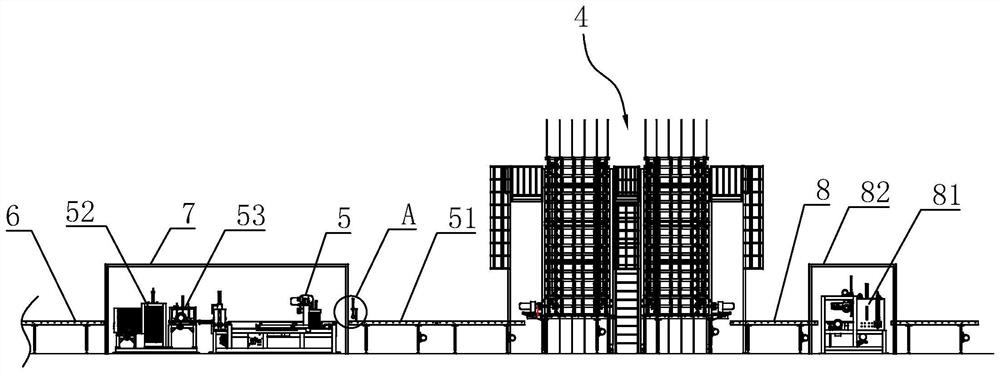

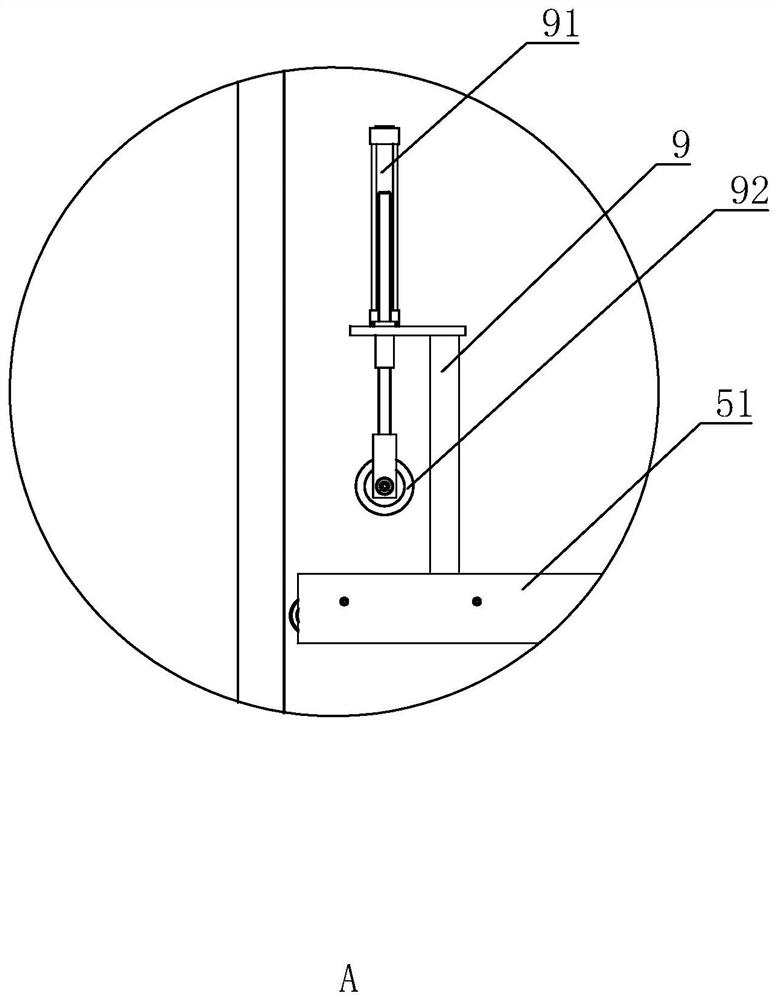

Welding sealing system and welding sealing process

ActiveCN111302299AControl air pressureHigh purityDecorative surface effectsSemiconductor/solid-state device manufacturingThermodynamicsProcess engineering

The invention discloses a welding sealing system. The device comprises a gas filling module, a baking module, a welding module and a conveying module, the vapor content of less than 100PPM in the device can be realized, the internal gas pressure of the packaging body can be controlled within + / -500Pa, the purity of the backfill process gas is ensured to be higher than 99.5%, and the sealing requirements of military special processes such as energy storage welding sealing and the like are met. The four modules of the welding sealing system can operate independently and can also work cooperatively, the automation degree is high, and the mass production requirement can be met. The invention further discloses a welding sealing process, and the welding sealing system is applied, so that energystorage welding sealing of low-water-vapor and high-purity process gas can be realized.

Owner:BEIJING CHENJING ELECTRONICS

Food cold and heat energy-saving drying equipment

InactiveCN110094961AScientific and reasonable structureSafe to useDrying gas arrangementsDrying machines with progressive movementsDry gasProduct gas

The invention discloses food cold and heat energy-saving drying equipment. The food cold and heat energy-saving drying equipment comprises a shell; through holes are formed in the middle parts of thetwo ends of the shell; a conveying belt is arranged on the middle part of the inner wall of each through hole; rotary shafts are arranged on the middle parts of the two ends of the inner wall of the conveying belt; the middle part of one end of each rotary shaft is connected with a motor; a first air inlet is formed in the edge part of the top end of the shell; the top end of the shell is providedan exhaust hole positioned at the position of one side of the first air inlet; and the top end of the shell is provided with a second air inlet positioned at the position of one side of the exhaust hole. The food cold and heat energy-saving drying equipment is scientific and reasonable in structure, is safe and convenient to use, can filter the dried gas through the second air inlet, a notch, a connecting plate, adsorbing sponge and a supporting net, reduces water vapor in the gas, can reduce harmful substances in the gas so as to enable the dried gas to preheat food, can facilitate mountingand change of the connecting plate by the notch, and reduces the mounting and change difficulty of the connecting plate.

Owner:湖州鑫宇电器科技有限公司

Antifogging crosslinked thermal shrinkage film and preparation method thereof

The invention discloses an antifogging crosslinked thermal shrinkage film and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing raw materials in an outer layer, a core layer and an inner layer, separately, then adding the raw materials into extruding equipment to be melted, separately, and passing the melted raw materials through a co-extrusion layer to obtain a compound melt; blowing the compound melt primarily, and cooling and sizing a primarily blown film bubble to form a pipe film; crosslinking linear molecular chains of the pipe film by electronic radiation; after pre-heating, carrying out secondary blowing and longitudinal drawing to obtain a compound film; and carrying out post-treatment sizing on the compound film, and trimming androlling the compound film to obtain the antifogging crosslinked thermal shrinkage film. An antifogging agent is relatively quick to play a role. When the antifogging crosslinked thermal shrinkage film is used as a packaging bag, the condition that the packaging bag is not transparent as water drops or fog state liquids are formed on the surface of the antifogging crosslinked thermal shrinkage film in a low-temperature environment is avoided. On the contrary, water vapor can be reduced effectively and the film is condensed to a liquid state water film, so that the inner side of the crosslinkedthermal shrinkage film is more transparent and higher in glossiness.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD +1

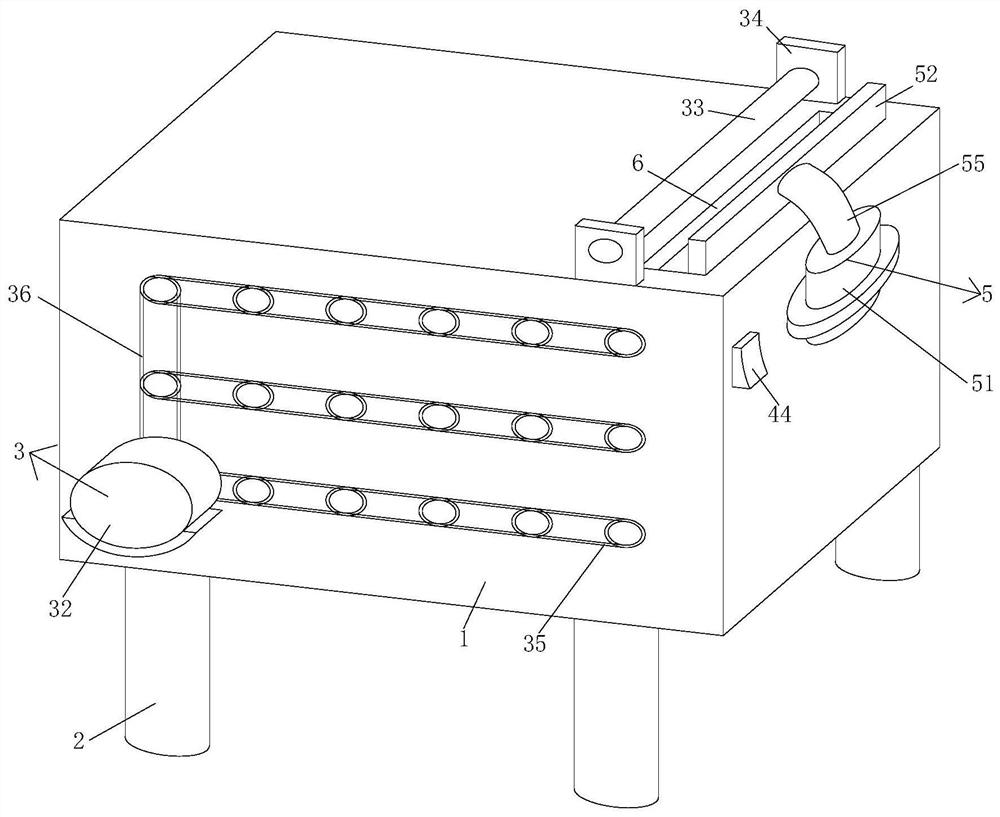

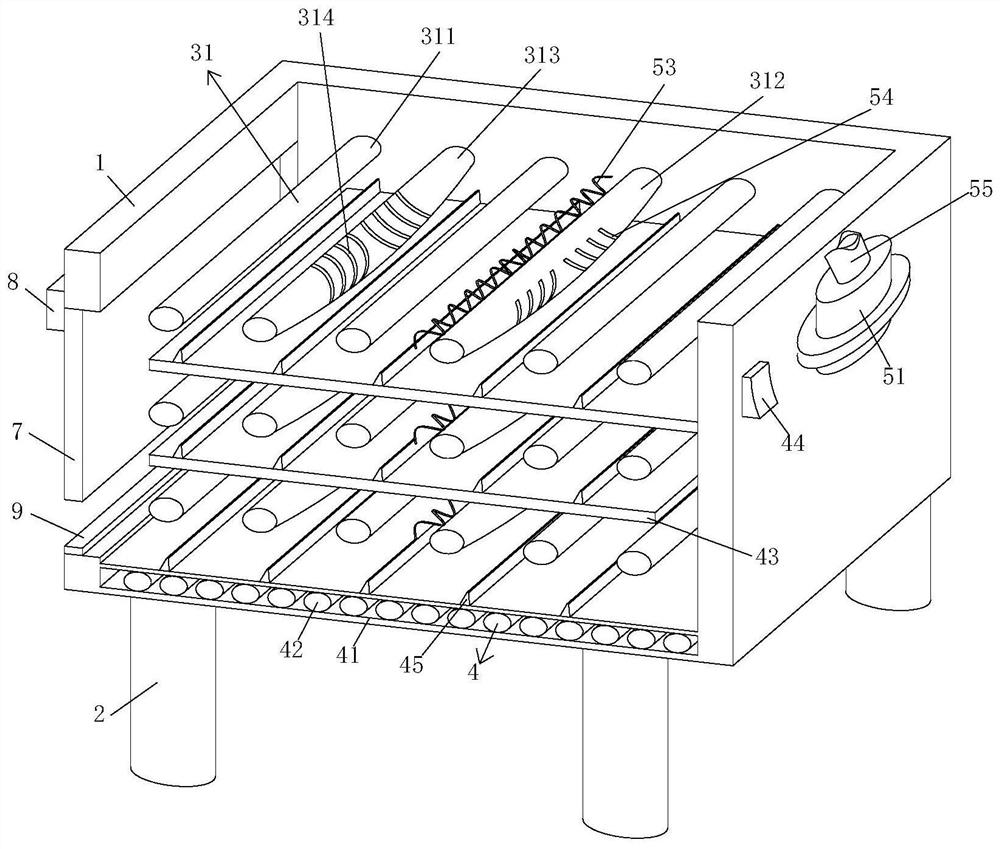

Textile drying device based on negative suction circulation drying in narrow space

InactiveCN111998644AExtension of timeTake advantage ofDrying gas arrangementsDrying machines with progressive movementsProcess engineeringHeat energy

The invention provides a textile drying device based on negative suction circulation drying in a narrow space, and relates to the field of textile processing. The textile drying device comprises a drying box used for drying textile fabrics, supporting legs used for supporting the drying box, a multi-combination transmission mechanism used for transmitting cloths, a multi-level heat energy transfermechanism used for transferring heat and a negative suction wind circulating mechanism used for promoting wind drying of the textile fabrics. According to the textile drying device based on the negative suction circulation drying in a narrow space, according to the problems of large space and low heat energy utilization efficiency existing in the existing drying process of the cloths, a special cloth transmission structure is designed, a heat energy transmission structure and an air circulation structure can fully promote the wind energy and heat energy to dry the cloths, and the problems that the drying space of a general textile drying device is large, the heat energy used in the drying process of the cloths is limited, a large amount of heat is lost, the waste of energy is caused, andthe utilization efficiency of heat energy is affected to a certain extent are solved.

Owner:胡长凤

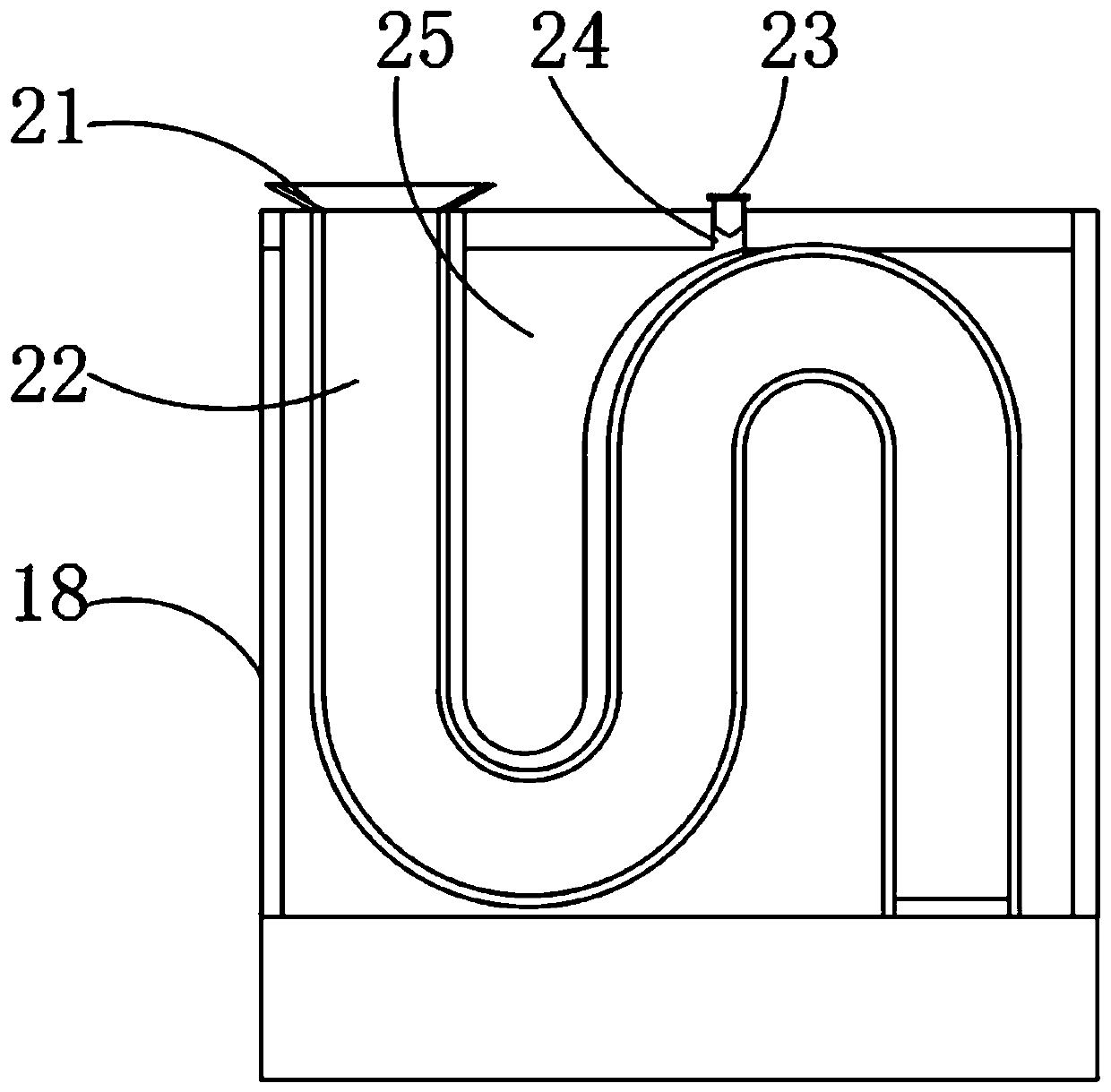

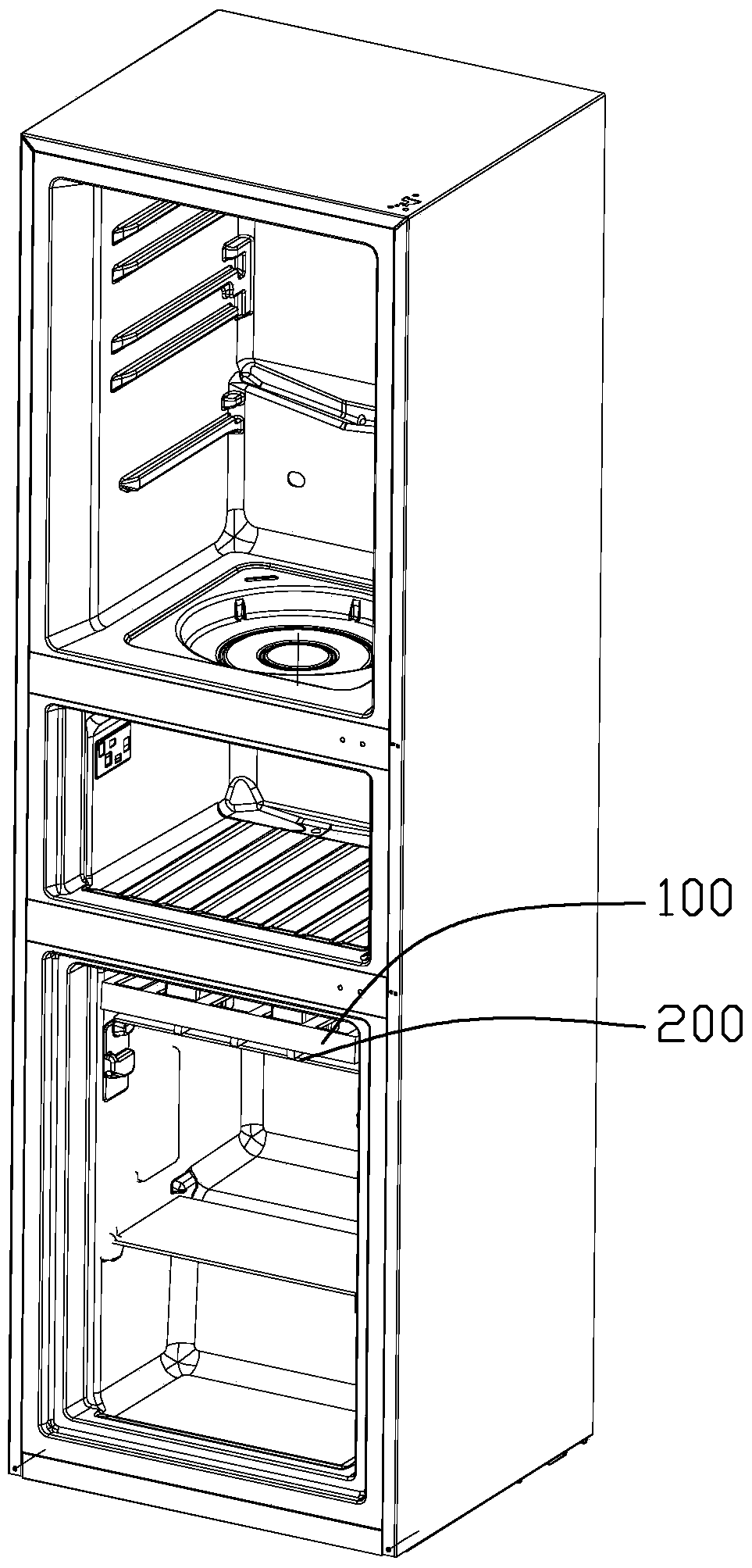

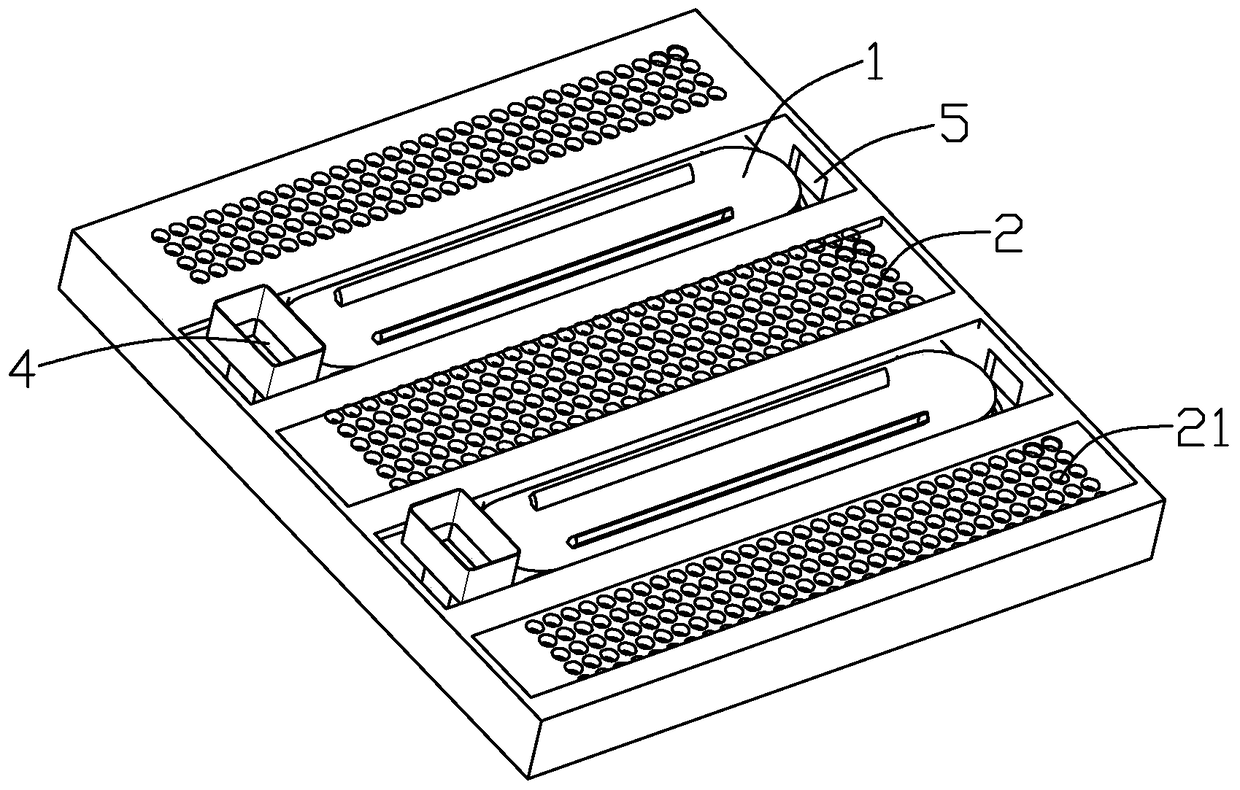

Refrigerator including ice tray and ice tray and manufacturing method for ice tray

InactiveCN106257171AEasy to manufactureUniform supplyLighting and heating apparatusIce productionFood storageEngineering

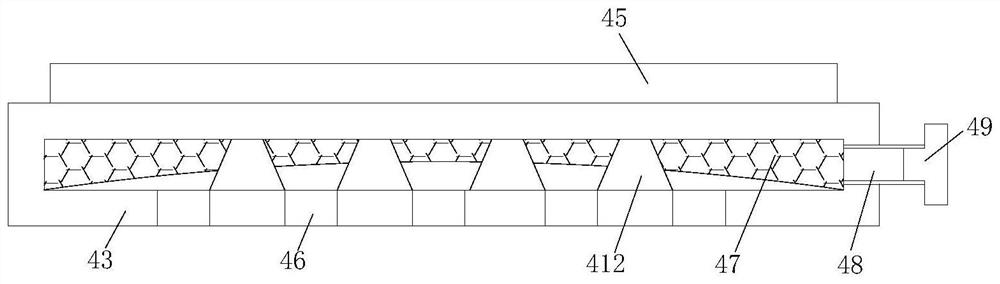

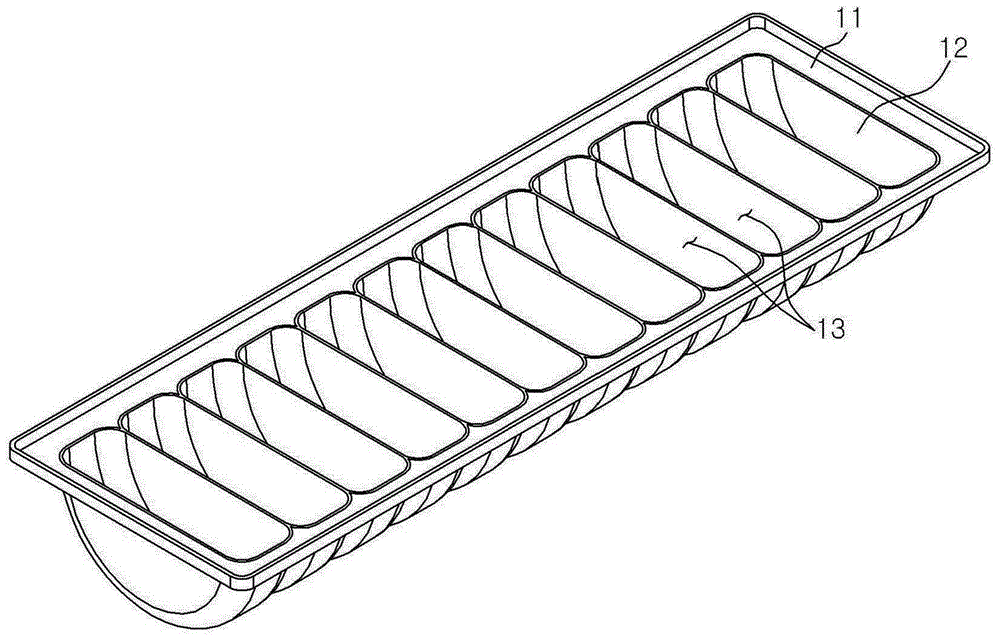

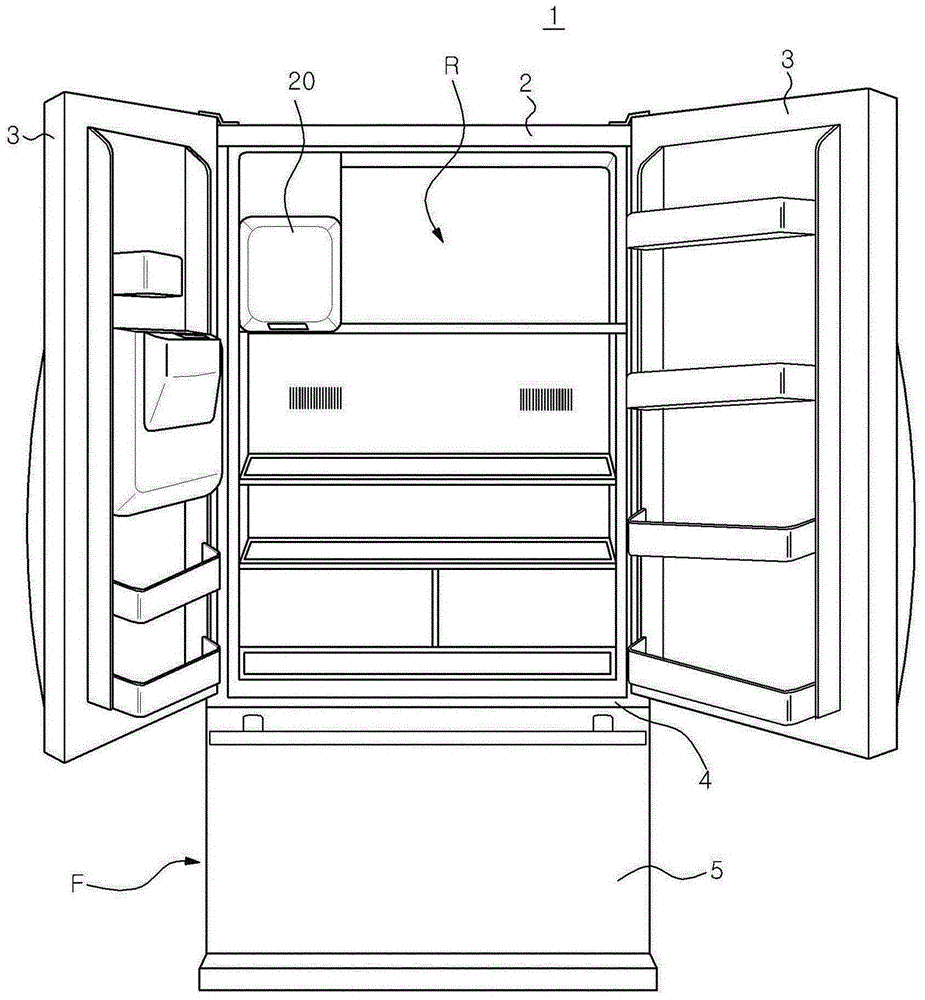

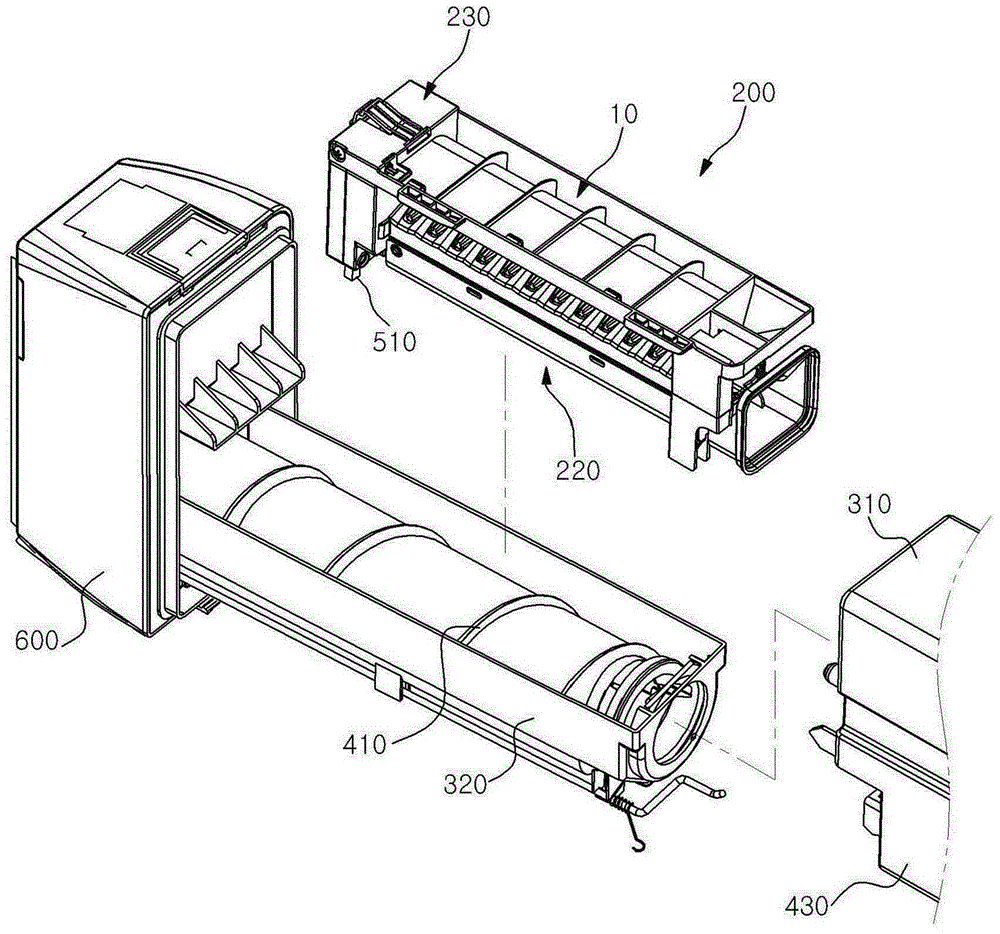

According to an embodiment, A refrigerator including an ice tray, comprising: a main body including a food storage space; a door installed in the main body and configured to open and close the food storage space; and an ice-making device installed in the food storage space, wherein the ice-making device comprises a case including a cooling space defined therein, a cooling unit configured to cool the cooling space, and an ice-making assembly disposed in the cooling space and configured to produce pieces of ice, the ice-making assembly including an ice tray having a plurality of independently-defined ice-making spaces and manufactured by pressing a metal at one time and a water supply unit configured to supply water to the ice-making spaces, the water supply unit comprises a feeder pipe configured to feed water to the ice-making assembly, and a water supply pipe coupled to the feeder pipe and disposed above the ice tray to extend along a longitudinal direction of the ice tray, and a plurality of water supply holes is formed in the water supply pipe in the positions corresponding to the ice-making spaces so that water is supplied to the respective ice-making spaces through the respective water supply holes.

Owner:DONGBU DAEWOO ELECTRONCIS CORP

Gas kitchen range and gas generator supplying gas to the same

InactiveCN101162093AIncrease the preheating cavityIncrease pressureDomestic stoves or rangesLighting and heating apparatusRural areaTar

The invention discloses a gas range and a generating furnace supplying gas for the gas range, relating to the industrial and household range field; the gas range consists of a range body(1), a range barrel body(5), a cold-hot gas shielding cover(8), a gas applicator(10), a gas purification barrel(11), an air inlet pipe(14), a gas purification disc(15), rang feet(18), a tar discharge pipe(20), a tar guiding pipe(22), an outer air inlet barrel(26) and an ignition device(30); the generating furnace consists of a furnace barrel body(44), a furnace core(61), an air duct(50), a hot water bucket(42), a furnace cover(35), a back taper place(37), a liquid drainage groove(38), an air applicator(51) and a sealing palace-type gas purification device; the invention has the advantages of convenient use and maintenance, high conversion efficiency of fuel, good effect of gas purification and strong fire power, etc.; the invention can fully use the agriculture crop wastes or flammable industrial and household wastes, thereby the invention is suitable to be used not only by dwellers in rural areas and small towns, but also by enterprises and institutions; moreover, the invention can also be used to dispose wastes for heat supply.

Owner:湖南中正机电设备有限公司

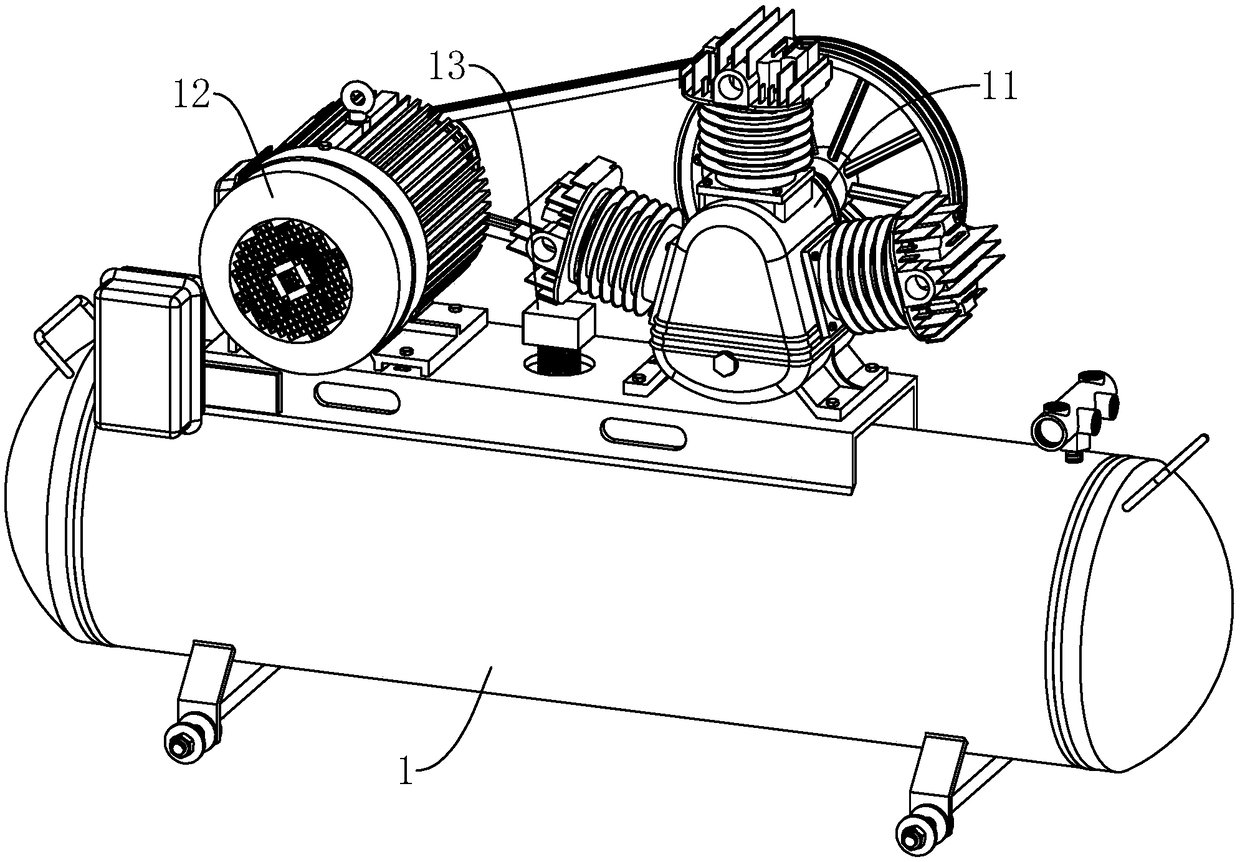

Air compressor

PendingCN109237298AExtended service lifeReduce corrosionGas treatmentVessel geometry/arrangement/sizeAir compressionGas compressor

The invention discloses an air compressor, and relates to the field of air compression. The air compressor comprises a tank body and a compression cylinder arranged on the tank body; a first cylinderis arranged at the inner end of the tank body; a first motor is arranged on an output shaft of the first cylinder; an output shaft of the first motor is located on the side, back away from the first cylinder; a mounting block is fixedly connected with the output shaft of the first motor; a plurality of first dehumidification brushes are arranged on the outer side wall of the mounting block; and each first dehumidification brush comprises a first brush bar connected to the mounting block and a first water absorbing head which wrap around the end of the first brush bar and is attached to the inner side wall of the tank body. Through the arrangement of the first cylinder and the first motor, the first dehumidification brushes rotate along an axial direction of the tank body and rotate along he circumferential direction of the tank body to comprehensively absorb the vapor condensed on the inner side wall of the tank body, thereby decreasing the vapor in the tank body, decreasing the corrosion caused to the inner side wall of the tank body by the water and prolonging the service life of the tank body.

Owner:浙江藤井空压机有限公司

Conveying type bowl and dish disinfecting device

InactiveCN107715138AReduce the presence of moistureUniform reflectionLavatory sanitoryHeatFiberInsulation layer

The invention discloses a transmission type dish disinfection device, which comprises a conveyor belt, a high-temperature disinfection chamber and a cooling chamber; the high-temperature disinfection chamber is provided with a material inlet and a material outlet; Connected; the conveyor belt runs through the high-temperature disinfection chamber and the cooling chamber. There are water seepage holes on the conveyor belt. There are dish racks on the conveyor belt at the feed port of the high-temperature disinfection chamber, and a water collection tank on the conveyor belt. There are dish racks, There are slides for supporting the dish rack on both sides of the symmetry, and buffer plates are provided at both ends of the slide; the inner wall of the high-temperature disinfection chamber is provided with an insulation layer, an ultraviolet reflection layer, and a dish rack from the inner layer to the outer layer in turn. The outer surface is covered with a fiber water-conducting layer, the high-temperature disinfection chamber is equipped with a sterilizing mechanism, and the cooling chamber is equipped with a cooling pipe. The invention can reduce the temperature of the dishes after being sterilized by high temperature, and prevent scalding during the process of arranging and taking the dishes.

Owner:陈思奇

Method for surface treatment of transparent part and part treated in this way

InactiveCN106457707AReduce the presence of moistureIncrease wavelengthFouling preventionVehicle headlampsOptical propertyTopography

A method for surface treatment of a transparent polymer part is disclosed, consisting of, in a first step, etching a determined topography of patterns in relief onto the external surface of a metal mould using a femtosecond laser and, in a second step, applying the mould under pressure onto the surface of the part to be treated, in such a way as to reproduce the patterns of the mould, in negative, on the part; said topography of patterns being adapted to the type of polymer, both to optimize the wettability of the surface preventing the formation of condensation on said surface and also so as not to affect the optical properties of the part.

Owner:PEZHO SITROEN AUTOMOBILS SA +1

A refrigerator deicing device

ActiveCN105371568BReduce the presence of moistureLighting and heating apparatusDefrostingFrostWater vapor

Owner:SHENYANG HAIER REFRIGERATOR

Continuous extrusion production line for PET foamed sheet

The invention discloses a continuous extrusion production line for a PET foamed sheet. The production line comprises an automatic feeding mechanism, a solid additive side feeding system, a multi-pathphysical foaming agent filling system, a drying-free system, a multi-stage melt pressurization system, a melt homogenizing system and distributed outputting and converged forming molds. Materials aresubjected to double-step mixing extrusion by a double-screw extruder and a single-screw extruder and are connected with a melt cooling system. A foamed sheet produced by the combined system enters a cooling forming system, and the cooling forming system comprises a multi-roller cooling flattening system, a cooling carrier roller system, an auxiliary traction system, a side edge shaping and transverse cutting system, a multi-stage cooling overturning frame and a double-face shaping system with grinding and planing functions. The production line has the technical effects that PET raw materials can directly enter an extrusion system without drying treatment, the viscosity of the materials is not reduced, the vacuum degree is adjustable, the melt cooling rate is easy to control, different types of physical foaming agents can be adopted, the addition amount is accurately controlled, and the foamed sheets with different densities are produced.

Owner:NANJING CHUANGBO MACHINERY

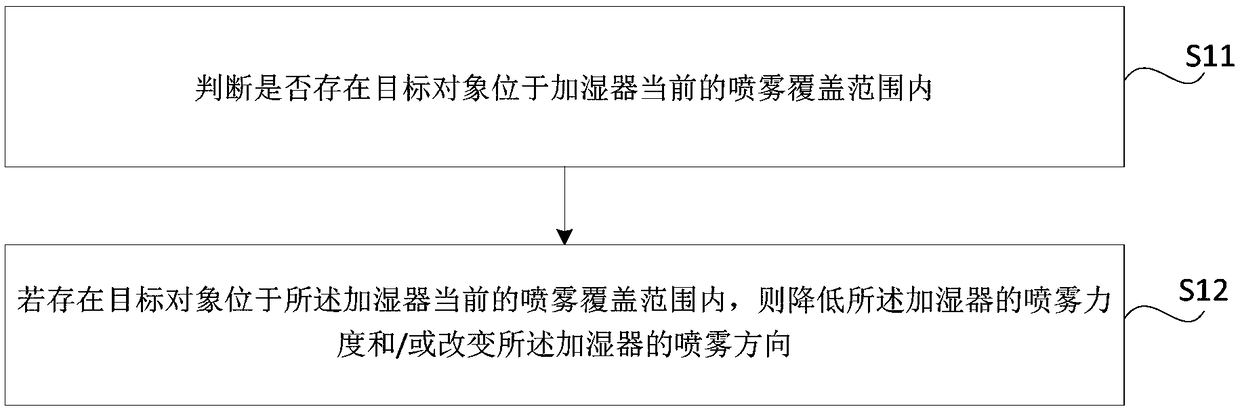

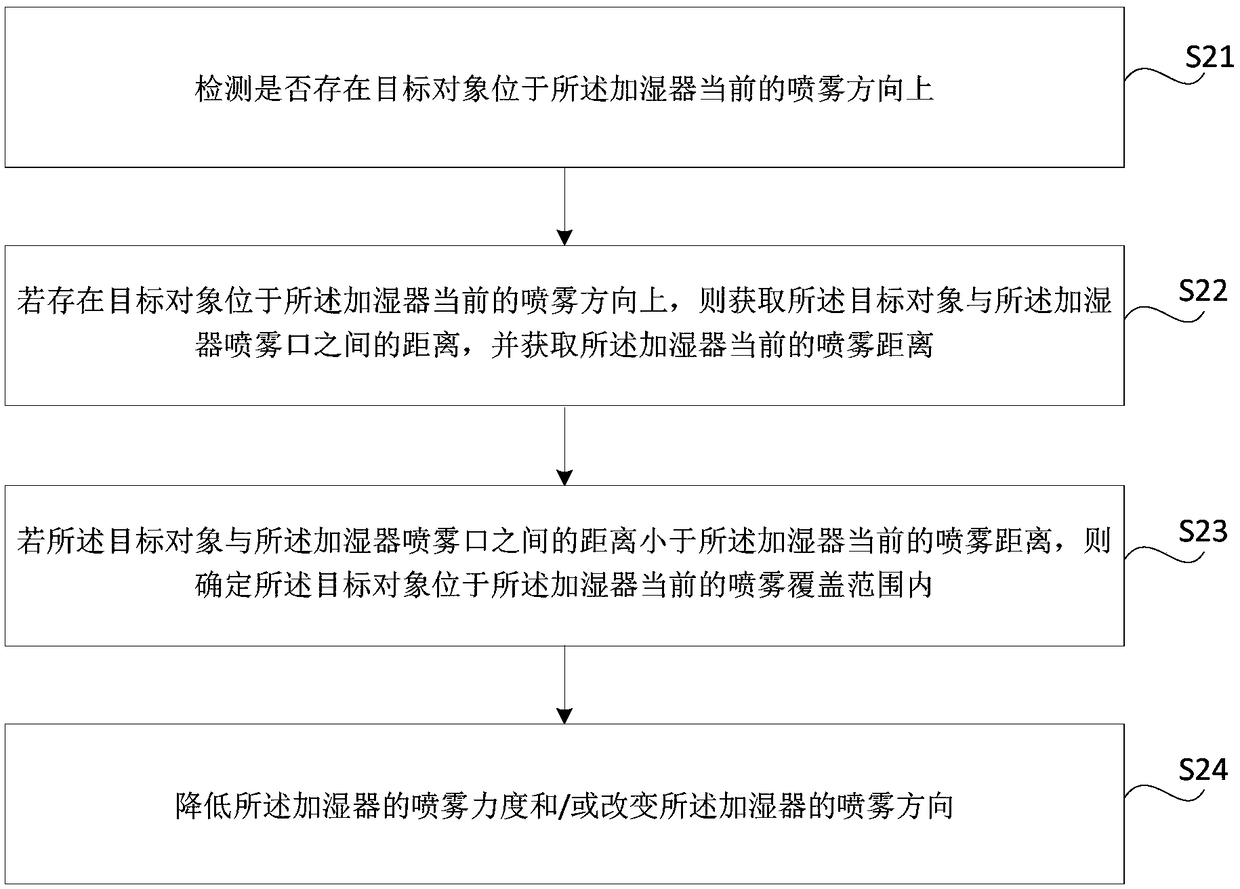

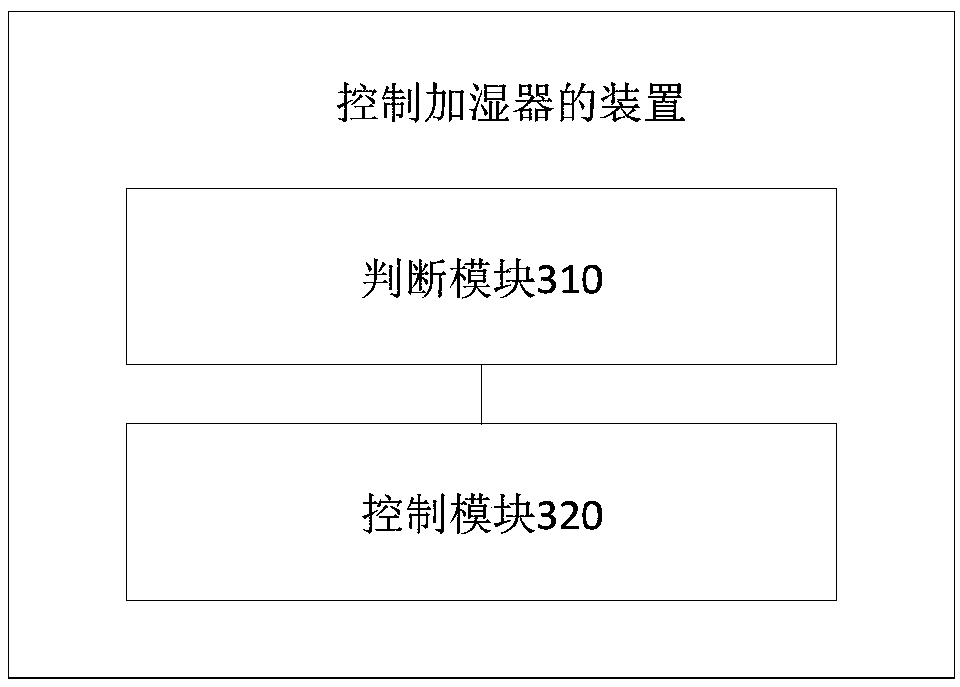

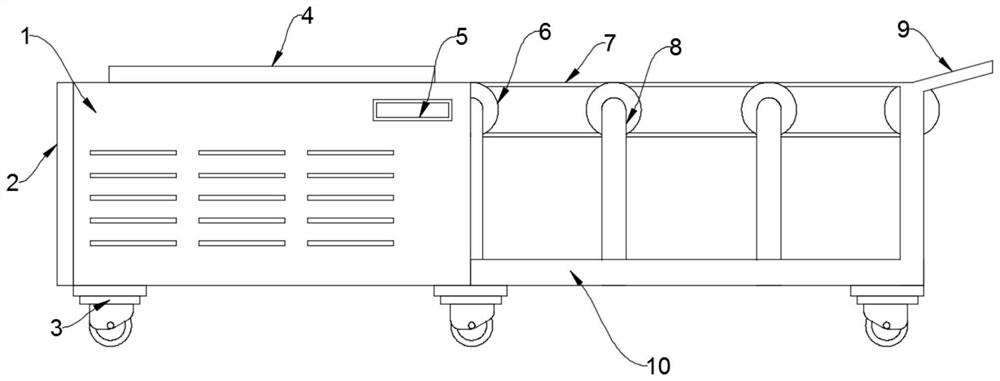

Method and device for controlling humidifier as well as storage medium

PendingCN108870675AReduce spray intensityChange spray directionMechanical apparatusEfficient regulation technologiesComputer scienceHumidifiers

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

A drying device specially used for glazed glass digital inkjet printer

Owner:江苏佳成特种玻璃制造有限公司

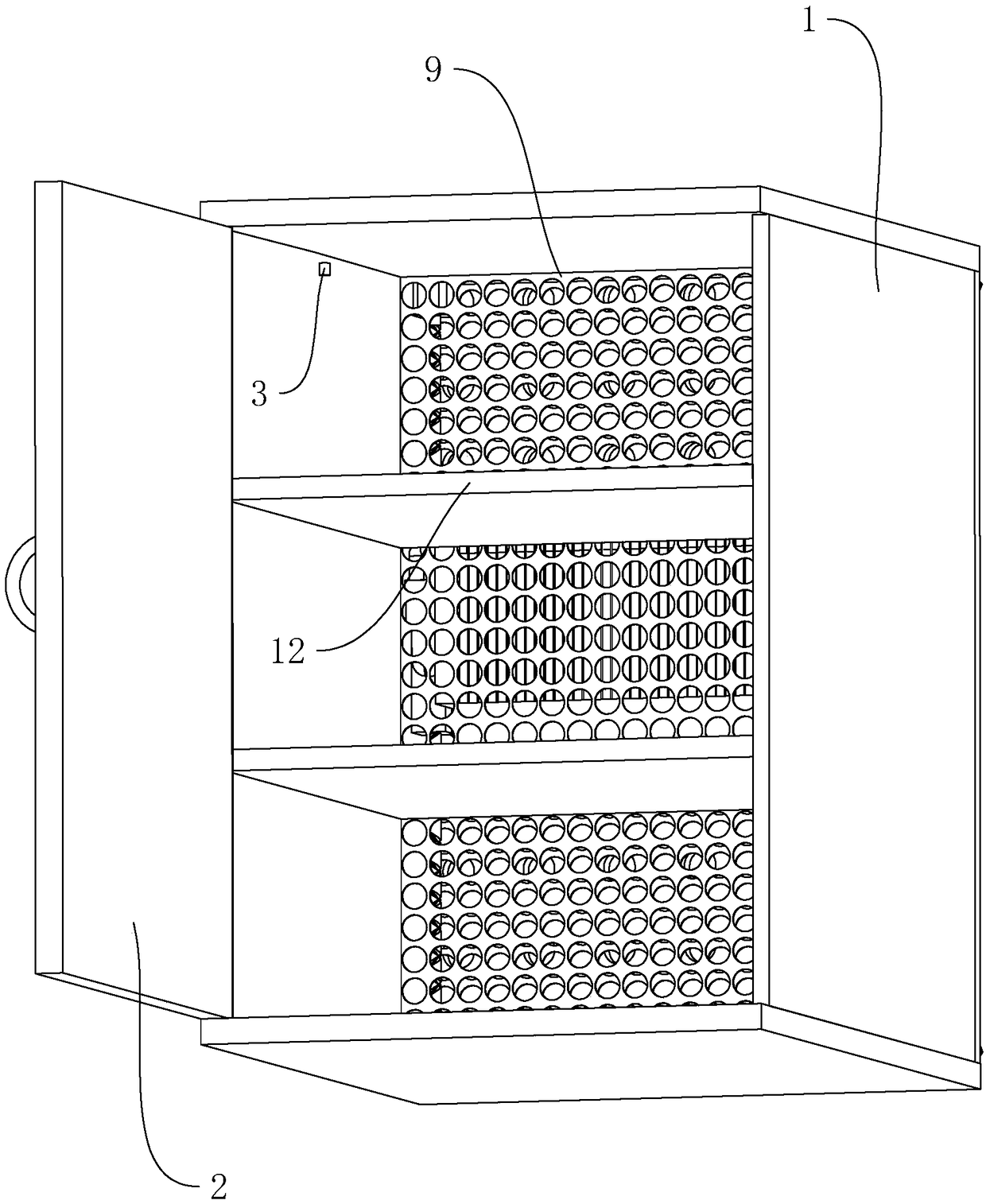

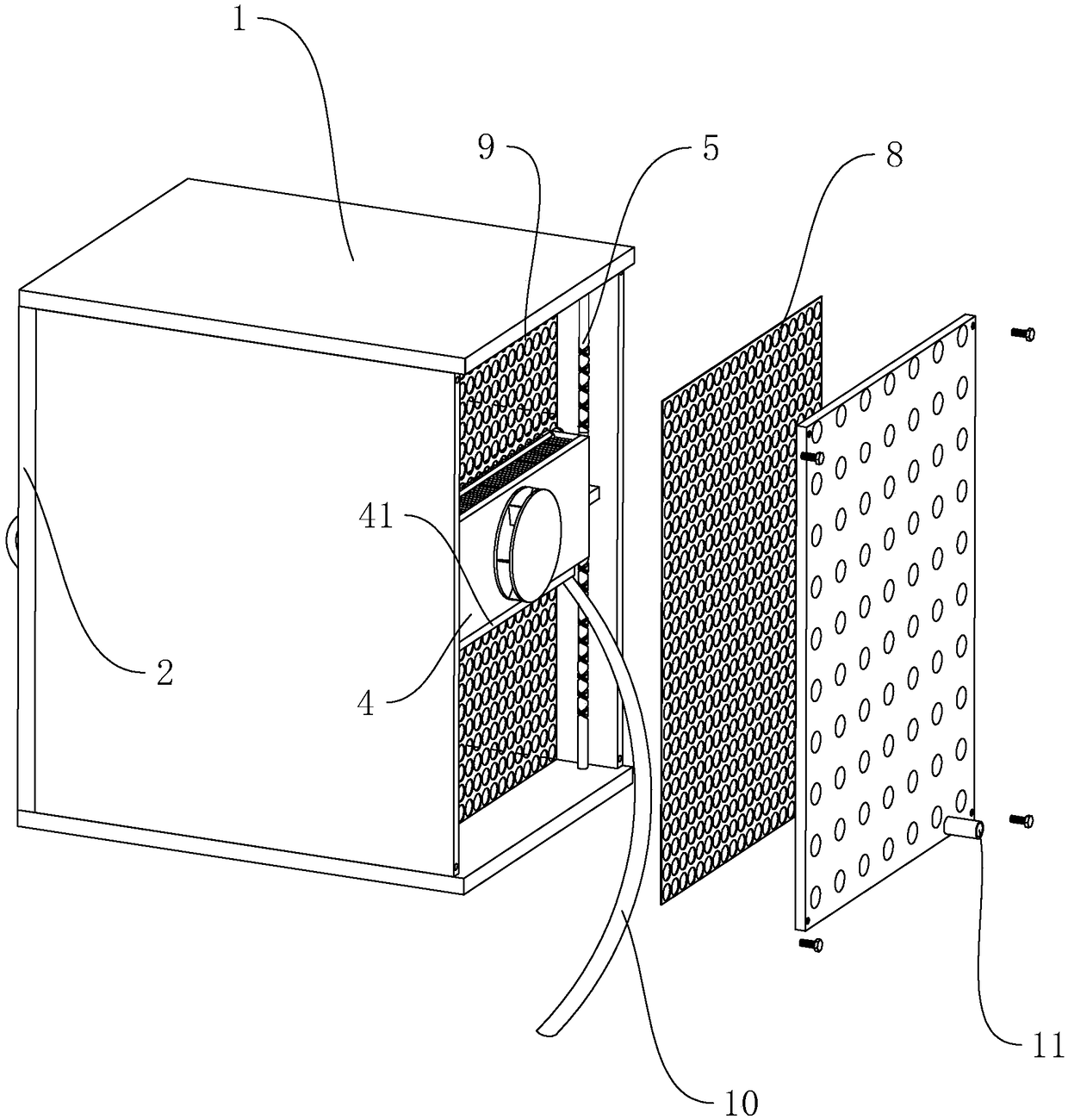

File cabinet

The invention relates to the technical field of office supplies, and aims to provide a file cabinet which comprises a cabinet body, the cabinet body is provided with a cabinet door, and the cabinet body is internally provided with a humidity sensor and a dehumidifier for extracting moisture in the cabinet. A screw is connected on one side of the dehumidifier vertically in the cabinet body in the rotating mode. The dehumidifier is in sliding connection on the screw. The cabinet body is provided with a guiding member for guiding the dehumidifier to move along the length direction of the screw. The screw is provided with a driving mechanism for driving the screw to rotate, the dehumidifier is connected with a first switching member for controlling the dehumidifier to work, and the driving mechanism is connected with a second switching member for controlling the driving mechanism to work. The first switching member and the second switching member are each connected with a control mechanismfor controlling the action. The file cabinet is applicable to storage and preservation of documents and materials.

Owner:广州市普菲科办公家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com