Intelligent gas circuit management system and control method thereof

A technology of management system and control method, applied in the field of intelligent air path management system and its control, can solve problems such as poor air filtration and purification effect, inability to meet severe weather, etc., to reduce water vapor and impurity content, avoid freezing phenomenon, improve adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

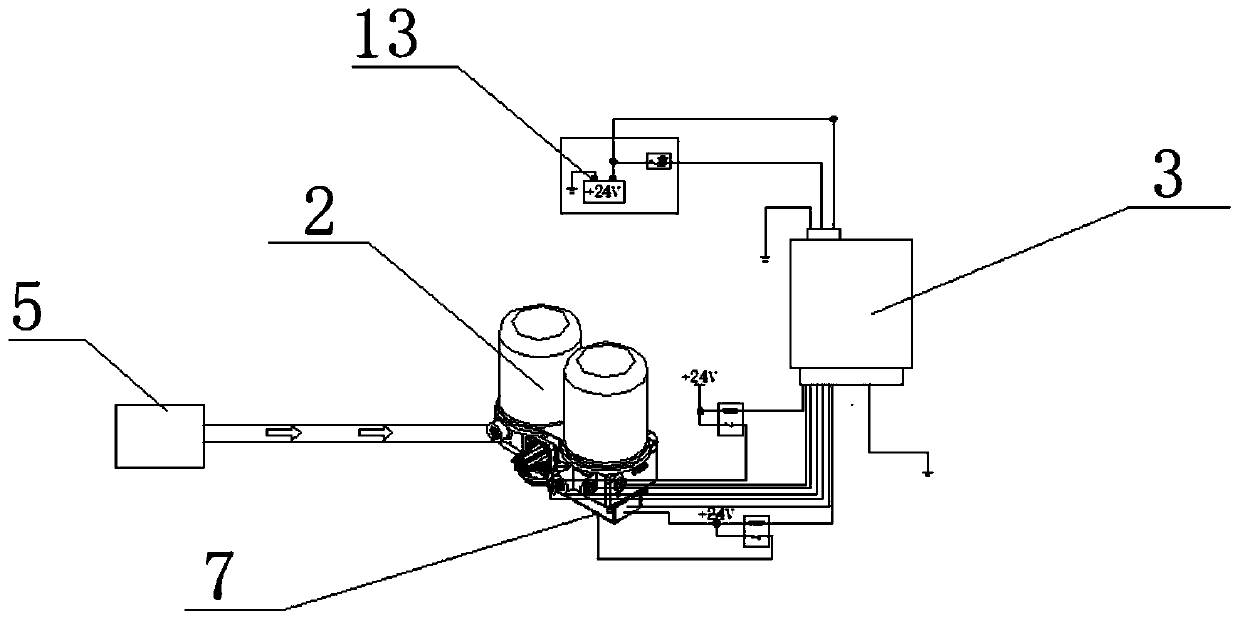

[0048] Such as figure 1 As shown, this embodiment discloses an intelligent gas circuit management system, which includes an air compressor 5, an ECU control module 3, a dryer device 2, a heater 1 installed on the dryer device 2, and at least A first intelligent drain valve 7 installed at the bottom of the dryer device 2, the air inlet port 201 of the dryer device 2 communicates with the air compressor 5 through an air circuit, and the ECU control module 3 communicates with the air compressor through a circuit respectively. The press 5, the heater 1 and the first intelligent drain valve 7 are connected in control.

[0049] In this embodiment, the drier device 2 dries and filters the gas provided by the air compressor, and at the same time, the heater can ensure that this step is carried out at a temperature not lower than a certain temperature, effectively avoiding the occurrence of freezing, and improving the filtration, drying effect.

Embodiment 2

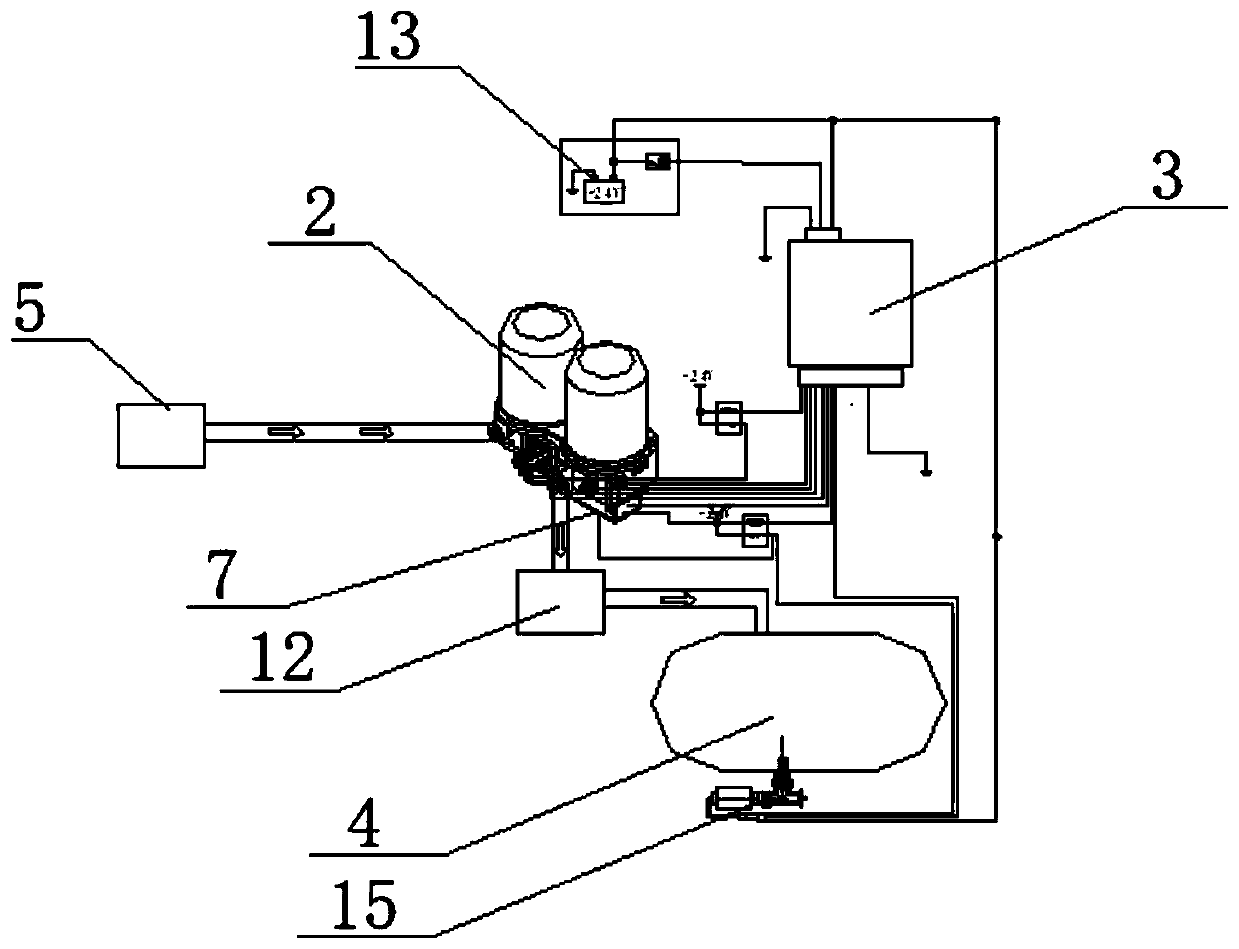

[0051] Such as figure 2 As shown, this embodiment is based on Embodiment 1. The gas circuit management system also includes an air storage tank 4 and at least one second intelligent drain valve 15, and the second intelligent drain valve 15 is installed at the bottom of the air storage tank 4 , and the gas storage tank 4 and the gas outlet port 202 of the dryer device 2 communicate with the four-guarantee valve 12 through the gas path, and the gas storage tank 4 stores the gas after drying and purification by the dryer device 2. In this embodiment The accumulated water at the bottom of the air storage tank 4 is discharged through the second intelligent drain valve 15 .

Embodiment 3

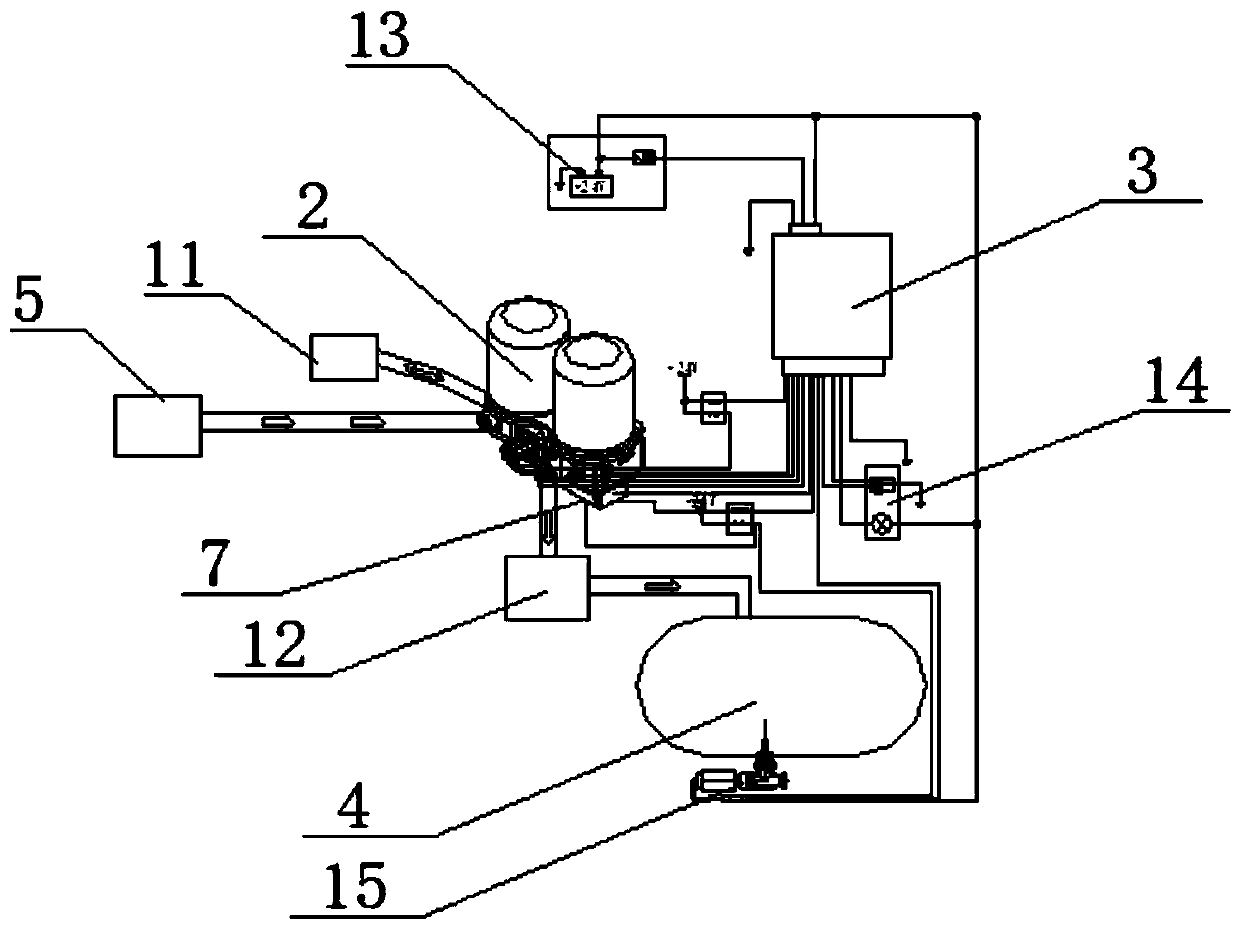

[0053] Such as image 3 In this embodiment, on the basis of Embodiment 2, a heating module 6 is installed inside the first intelligent drain valve 7 and the second drain valve 15, and the heating module can ensure the working environment of the first and second intelligent drain valves. Reduce the occurrence of icing; the smart drain valve 7 can be the smart drain valve in our company's application number 201821739585.9, or other types of drain valves with or without heating.

[0054] Wherein, the gas path management system also includes a regeneration tank 11 and a drain switch 14, the regeneration tank 11 communicates with the dryer device 2 through a gas path, and the drain switch 14 is respectively connected to the first intelligent drain valve 7, The second intelligent drain valve 15 is controlled and connected, and the drain switch 14 of this embodiment can perform manual self-drainage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com