Device used for cooling sheet-shaped laser gain media

A gain medium and sheet laser technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of inability to accurately control the working temperature of the gain medium, medium damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

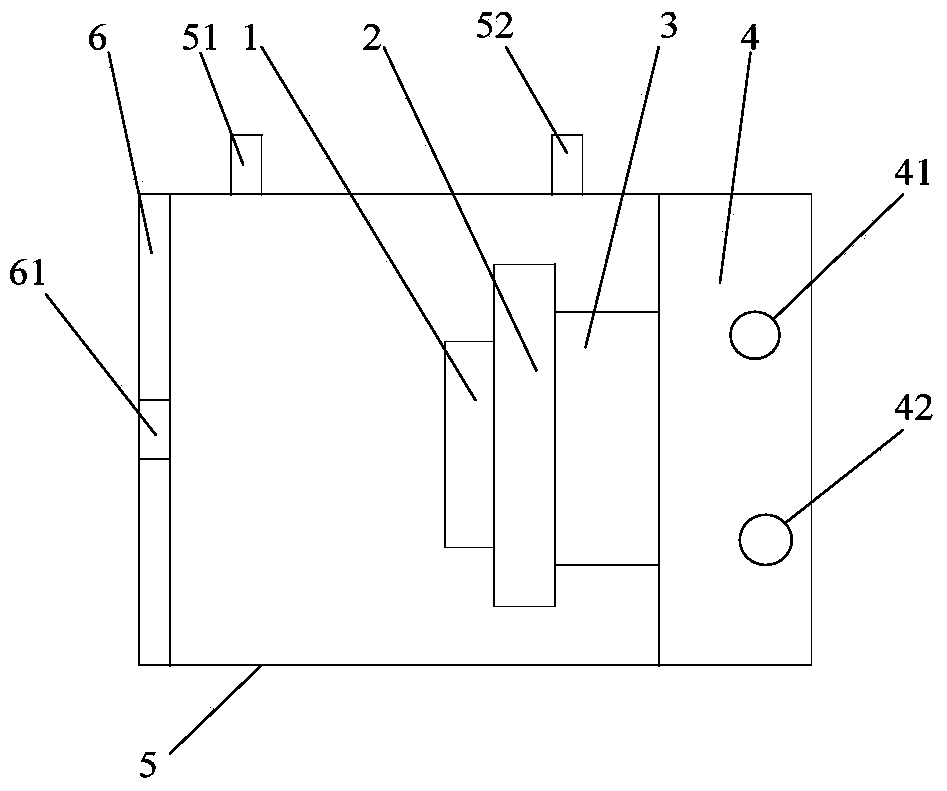

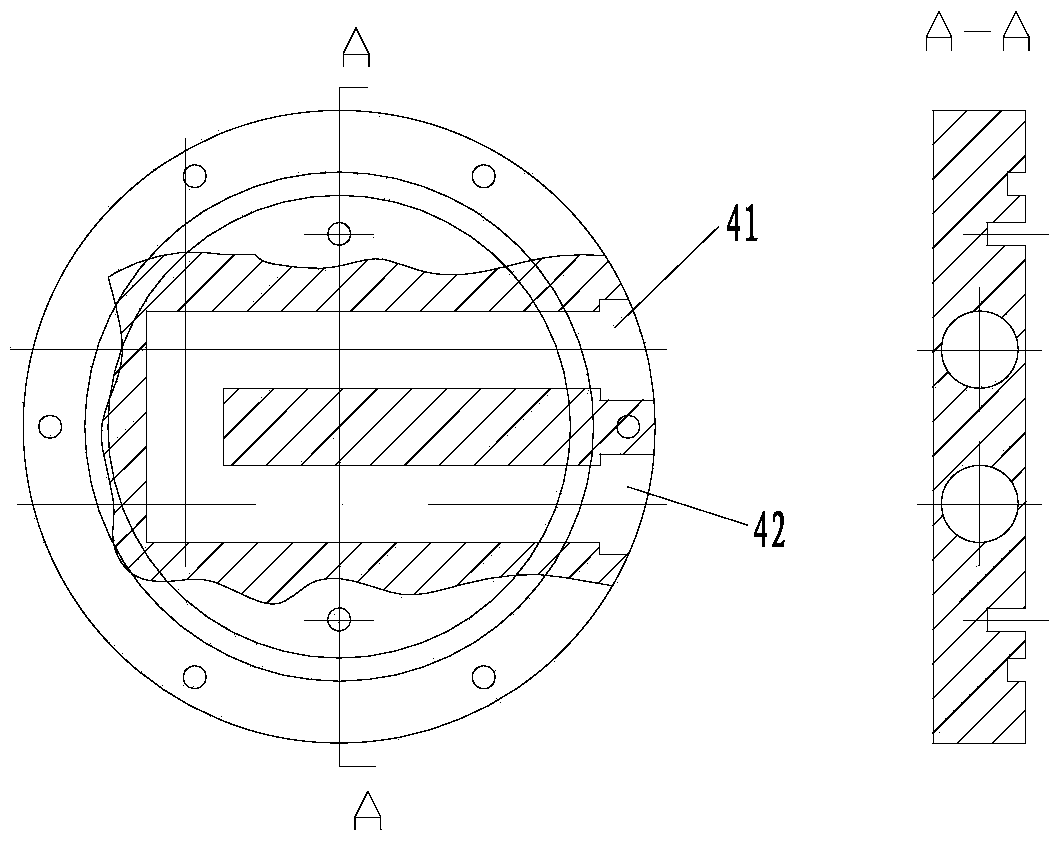

[0014] like figure 1 As shown, the sheet-shaped laser gain medium 1 and the thermistor are fixedly arranged on the heat sink 2, the front surface of the sheet-shaped laser gain medium 1 is coated with a laser antireflection film, and the rear surface is coated with a 0-degree total reflection film, and is connected with the heat sink. Shen 2 surface contact. The fixing method between the sheet-shaped laser gain medium 1 and the heat sink 2 can be mechanically fixed by a clamp, or can be welded by using metal indium as a solder. The heat sink 2 is fixedly connected with the vacuum chamber base 4 through long bolts, and the TEC (semiconductor cooler) 3 is arranged between the heat sink 2 and the vacuum chamber base 4, and is clamped by the two. The cooling surface of the TEC3 and the heat sink 2 contact, the heating surface is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com