Air treatment system for machine room of hydropower station

A technology for air handling systems and hydropower stations, which is used in air conditioning systems, space heating and ventilation, and household heating, etc. It can solve the problem of erosion and oxidation of humid air in heat exchangers, damage to heat exchangers, and affecting the normal operation of electrical equipment in computer rooms, etc. problems, to achieve the effect of improving work stability, uniform heating, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

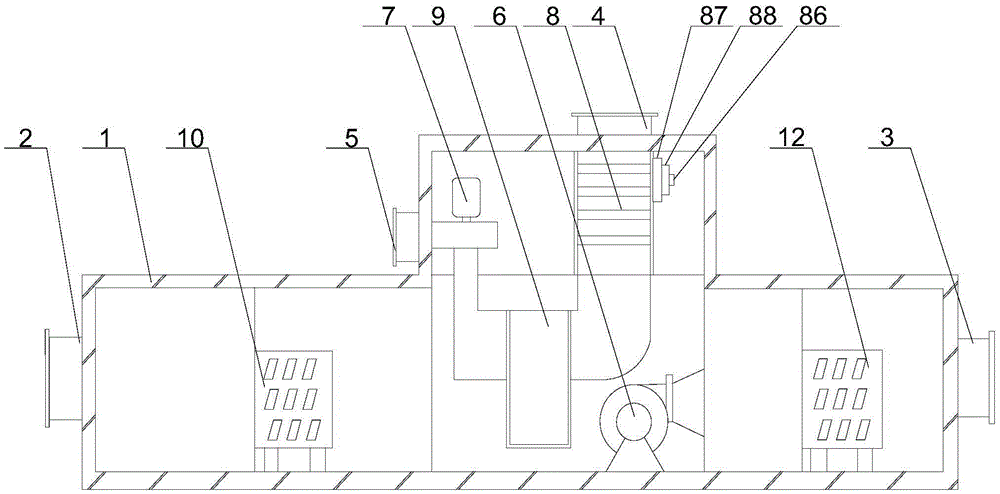

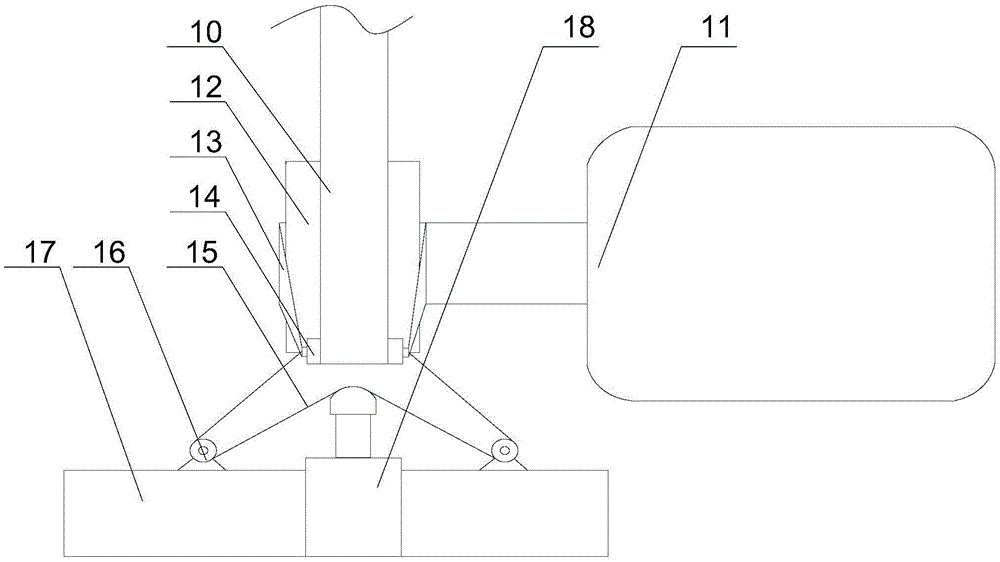

[0024] like figure 1 , figure 2 and Figure 5 As shown, the air treatment system of a hydroelectric power station machine room according to the present invention includes a casing 1, on which an air inlet 2, an air outlet 3, a regenerative air inlet 4 and a regenerative air outlet 5 are arranged, and the casing 1 1 is equipped with a fan 6, a heater 8, a dehumidification wheel 9 and a regeneration fan 7, one end of the fan 6 is connected to the air inlet 2, the other end of the fan 6 is connected to the air outlet 3, and the heater 8 is connected to the air outlet 3 respectively. The regeneration air inlet 4, the dehumidification runner 9 and the regeneration blower 7 are connected in sequence, and the other end of the regeneration blower 7 is connected with the regeneration outlet 5, and a pulley 12 is installed on the output end of the motor 11, and also includes a pulley 12 The roller 14 arranged tangentially, the pulley 12, the roller 14 and the dehumidification runner ...

Embodiment 2

[0028] like image 3 As shown, this embodiment is based on Embodiment 1, the connecting rod 13 is an elastic plastic rod, and the two ends of the elastic plastic rod are sleeved on the rotating shafts of the pulley 12 and the roller 14 respectively. In order to prevent the roller 14 from moving with the belt 10 when rotating, the connecting rod 13 connects the pulley 12 to the roller 14. When the roller 14 is pulled at the output end of the cylinder 18, the connecting rod 13 made of elastic plastic material will produce a small deformation to The movement of the rollers 14 is accommodated while ensuring favorable support of the rollers 14 .

Embodiment 3

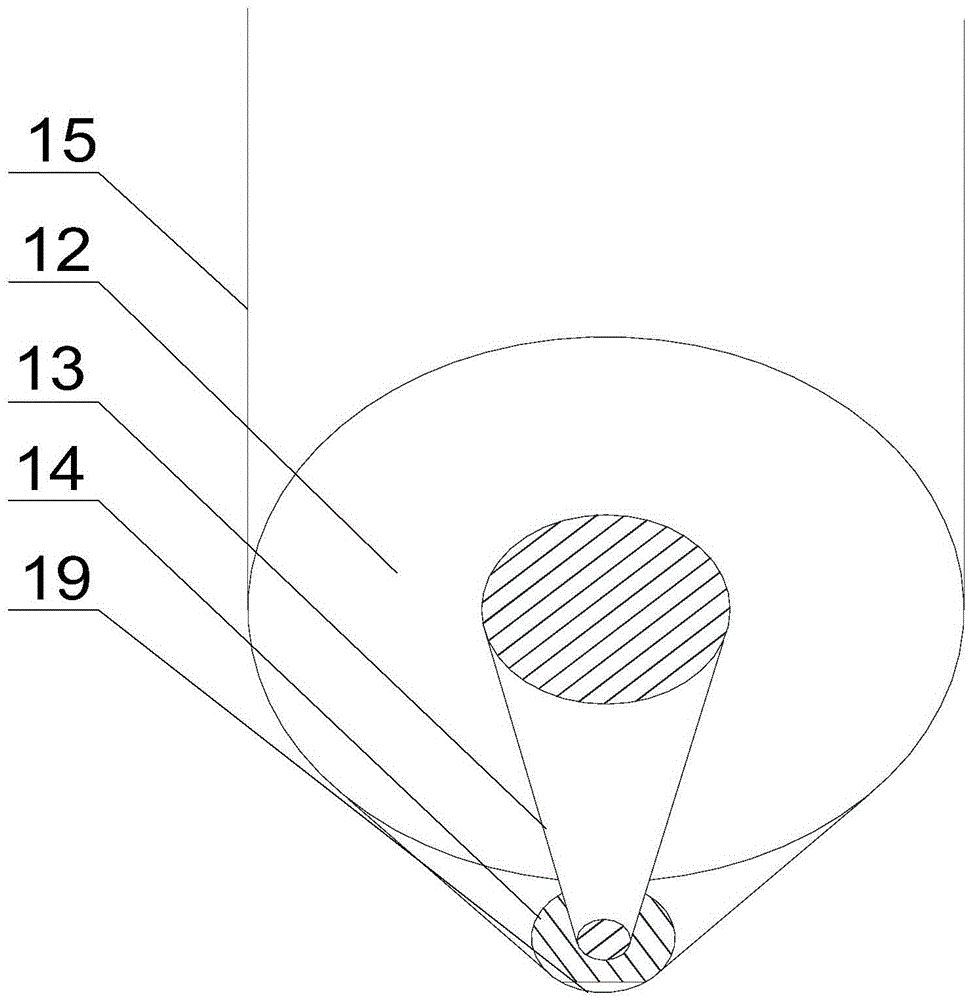

[0030] like Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, one end of the connecting rod 13 is provided with a through hole, the rotating shaft of the pulley 12 is in clearance fit with the through hole, and the other end of the connecting rod 13 is hinged with the rotating shaft of the roller 14. As preferably, a through hole is provided at one end of the connecting rod 13, and the rotating shaft of the pulley 12 fits in clearance with the through hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com