Adjusting structure of refrigerator storage rack

A technology for adjusting structures and racks, applied in household refrigeration devices, lighting and heating equipment, supports, etc., can solve the problems of easy falling, no positioning structure, unbalanced force, etc., to prolong the service life and adjust the number of stages. The effect of many, small adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

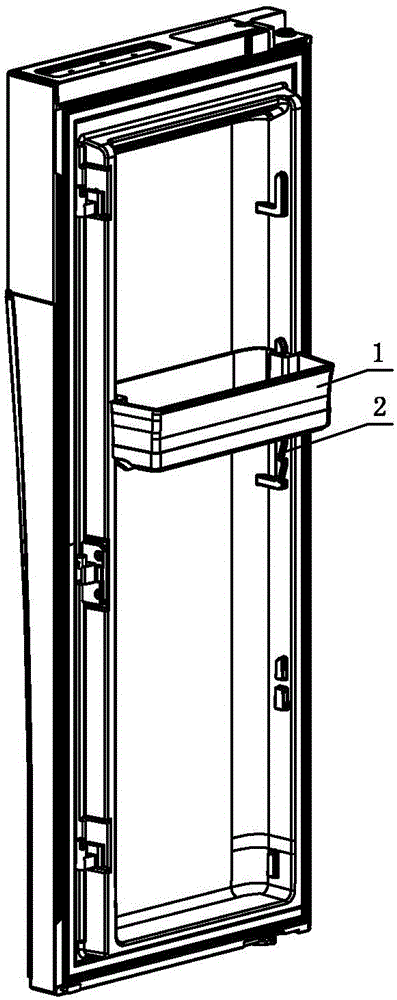

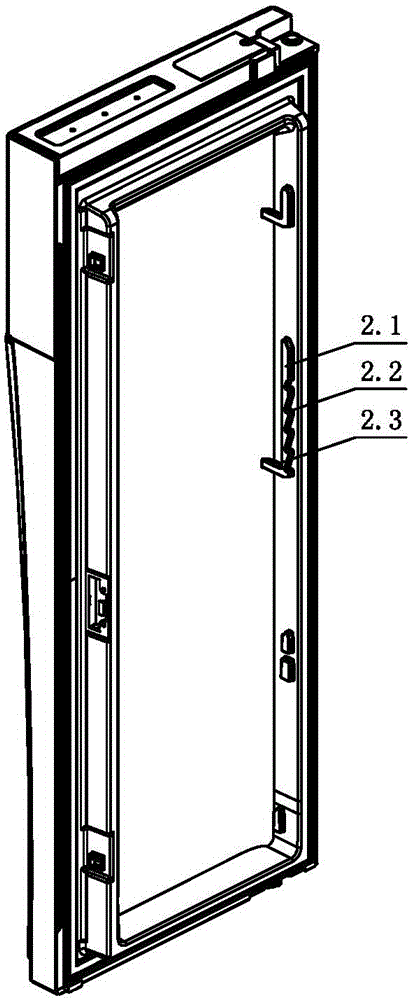

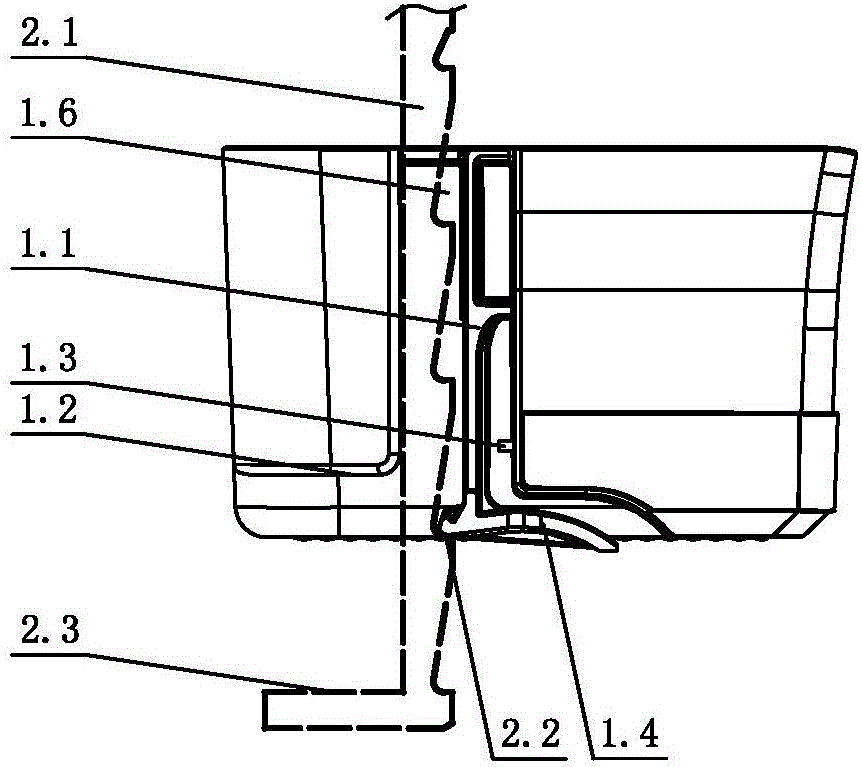

[0024] see Figure 1-Figure 6 , the adjustment structure of the refrigerator storage rack includes a door body and a storage rack 1, and the storage rack 1 is slidably arranged on the door body; the two sides of the inner wall of the door are respectively symmetrically provided with an adjustment mechanism 2, and the adjustment mechanism 2 is vertically arranged along the door body. The outer side of the adjustment mechanism 2 is provided with a sawtooth structure 2.1 with several tooth parts 2.2; the side wall of the storage rack 1 is movable with an adjustment hook 1.4, and the adjustment hook 1.4 acts on or separates from the tooth part 2.2; in the positioning state, the adjustment The hook 1.4 acts on any tooth part 2.2; when adjusting, adjust the hook 1.4 manually or with a tool, so that the adjustment hook 1.4 is separated from the tooth part 2.2, and the shelf 1 can slide up and down relative to the door body to adjust the height. After adjusting to an appropriate positi...

no. 2 example

[0036] see Figure 7 , the adjustment structure of the refrigerator storage rack is different from the first embodiment in that: one end of the swing rod 1.5 is connected to the middle part of the adjustment hook 1.4, the other end is hinged on the storage rack 1, and the swing rod 1.5 is connected to the storage rack 1. A spring 3 is arranged between them, so that the adjustment hook 1.4 can be elastically reset.

[0037] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 3 example

[0039] see Figure 8 , the adjustment structure of this refrigerator storage rack is different from the first embodiment in that: the setting of the swing rod 1.5 is cancelled, the middle part of the adjustment hook 1.4 is hinged on the storage rack 1, and a torsion spring (not marked in the figure) is arranged between each other. ), the adjustment hook 1.4 realizes the elastic reset rotation by the torsion spring.

[0040] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com