Gear-type fine tuning mechanism

A fine-tuning mechanism, gear-type technology, applied in belt/chain/gear, mechanical equipment, theodolite and other directions, can solve the problems of small adjustment range, difficult target alignment, jumping of sighting frame, etc., to achieve large adjustment range and high sensitivity , the effect of good craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

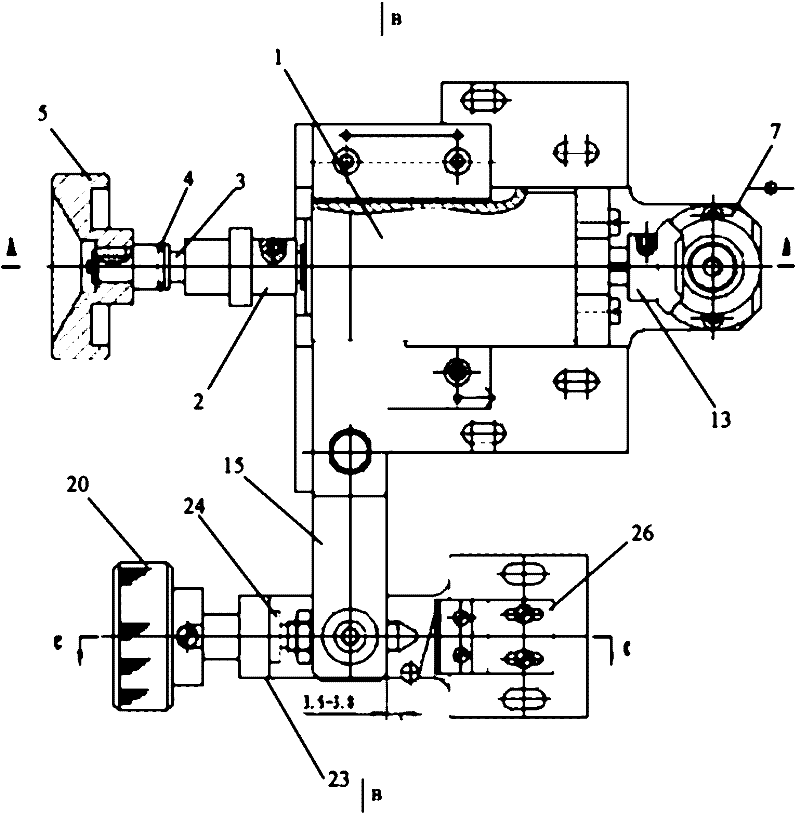

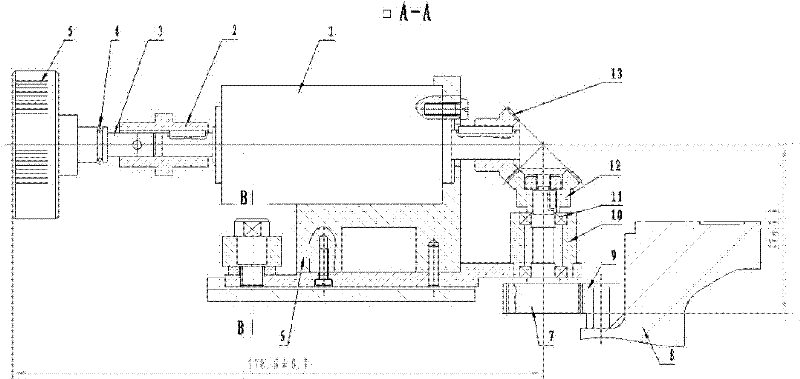

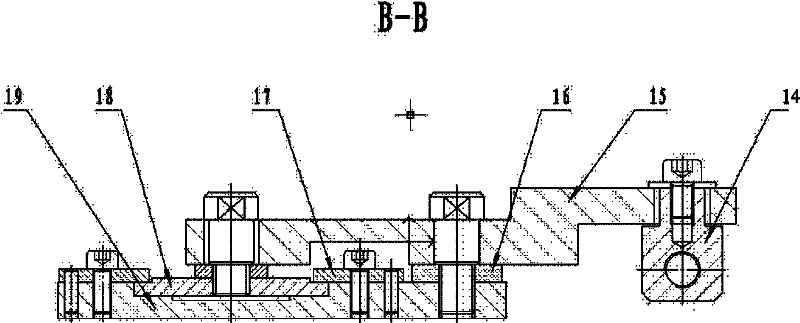

[0022] see Figure 1 to Figure 4 , the gear-type locking fine-tuning mechanism that the present invention proposes, is made of azimuth fine-tuning device and azimuth locking device, is all positioned at the theodolite head, and azimuth fine-tuning device comprises reduction box 1, connecting sleeve 2, fine-moving screw rod 3, sealing ring 4, Micro hand wheel 5, gearbox seat 6, gear shaft 7, bearing lower ring 8, gear 9, bearing sleeve 10, bearing 11, first bevel gear 12, second bevel gear 13, connecting nut 14, swing rod 15, washer 16. Guide plate 17, slide plate 18, fretting support plate 19. The azimuth locking mechanism comprises a locking hand wheel 20, a sealing ring 21, a nylon washer 22, a support plate 23, a locking screw 24, a switch seat 25, and a micro switch 26. The azimuth fine-tuning device and the azimuth locking device are connected through the swing rod 15; the micro-handwheel 5 is connected with the reduction box 1 through the micro-motion screw 3, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com