A side-slip mechanism in a wind tunnel that can realize positive and negative conversion of the side-slip angle and has a small blocking ratio

A technology of sideslip angle and blocking ratio, which is applied in the field of a mechanism to realize the side slip angle of the transformation model, which can solve the problems of reducing the blocking ratio, large size of the turntable, and large blocking, so as to reduce the blocking degree and make the installation simple and reliable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

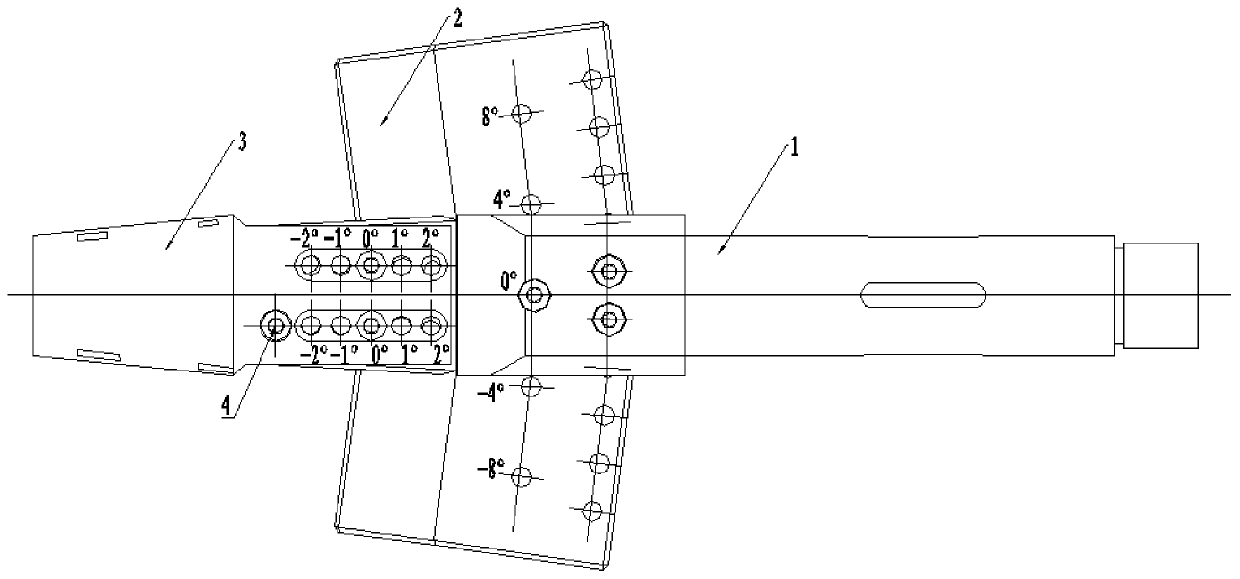

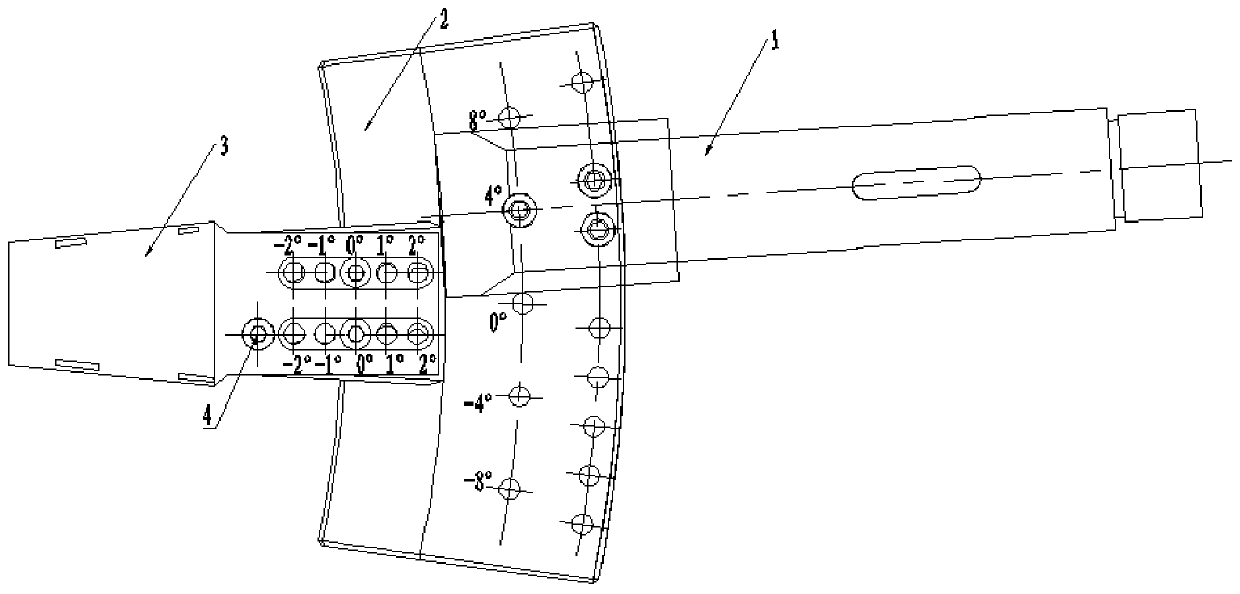

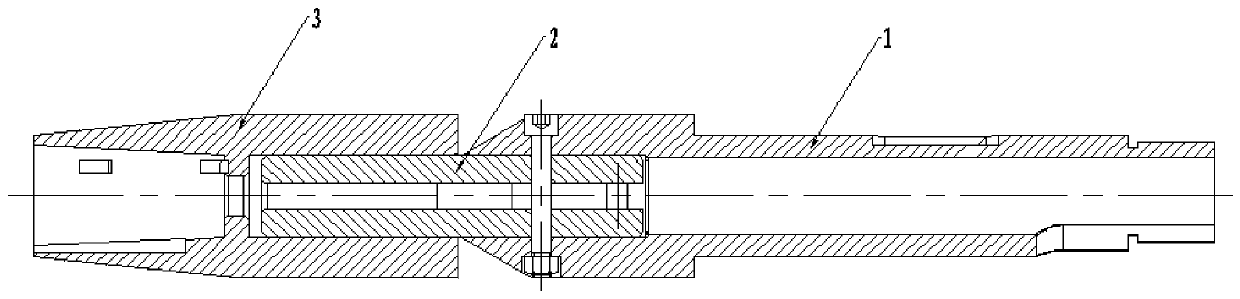

[0017] Such as Figure 1-3 As shown, the sideslip angle designed in this example ranges from -10° to 10°, and the minimum angle interval is 1°. The mechanism includes support 1, turntable 2 and joint 3, and support 1 and turntable 2 pass through three pin holes Connected, the turntable 2 is a fan structure with a mounting bump at the center, and the center part of the fan is inserted into the groove of the support 1.

[0018] Three pin holes are set on the groove of the support 1 for fixed connection with the pin holes on the fan surface, wherein one pin hole A1 on the groove of the support 1 is located on the axis of the support 1, and the other two pin holes are on the axis of the support 1. The pin holes B2 and C2 are located on the same arc segment H2; a pin hole A1 is set on the center line of the sector 0 ’, the interval angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com