A Flexible Body Torsional Stiffness Test Bench

A technology of torsional rigidity and flexible body, applied in the direction of applying stable torsion to test the strength of materials, etc., can solve problems such as complex structure, and achieve the effect of eliminating extra torque, high transmission efficiency and measurement accuracy, and general purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

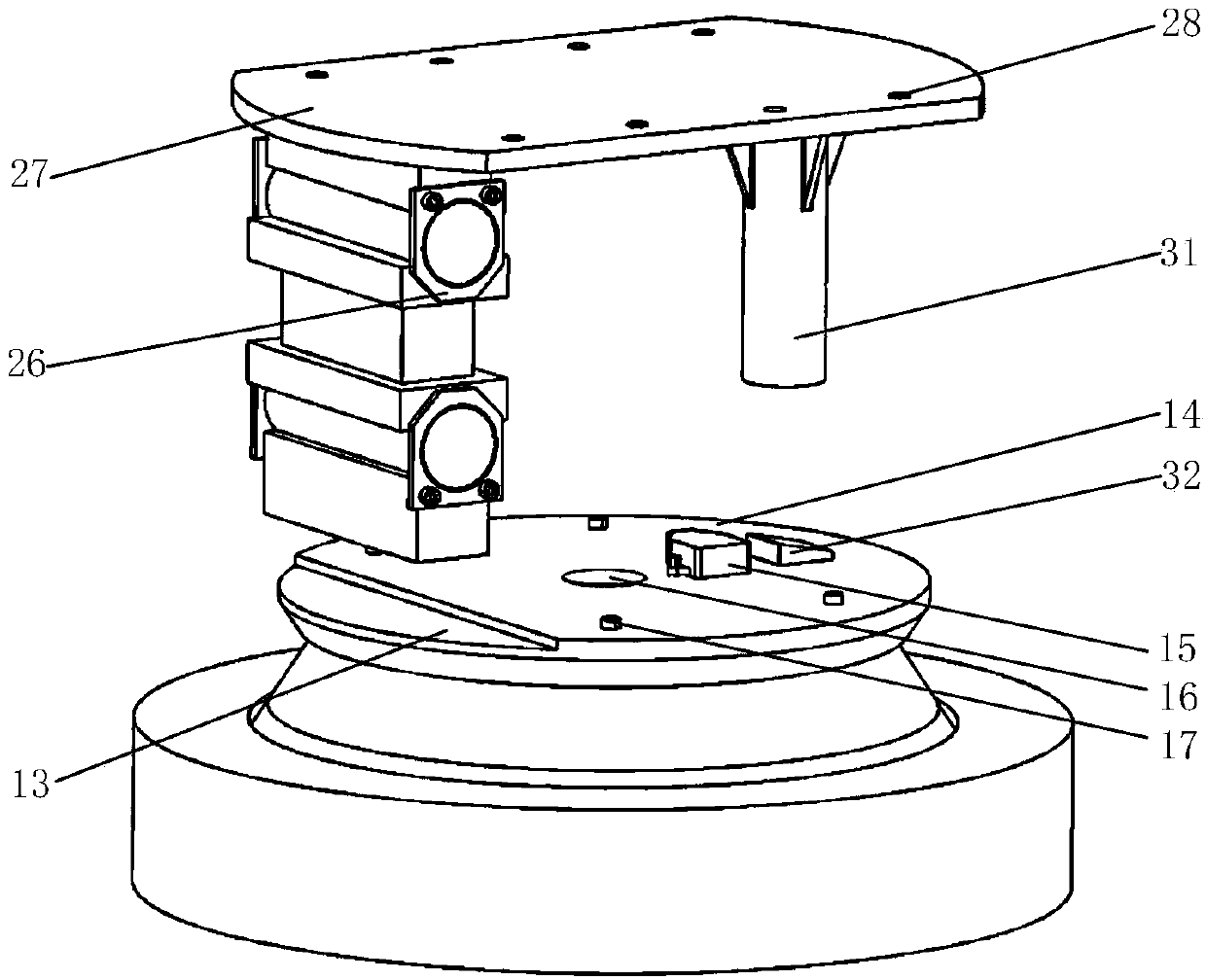

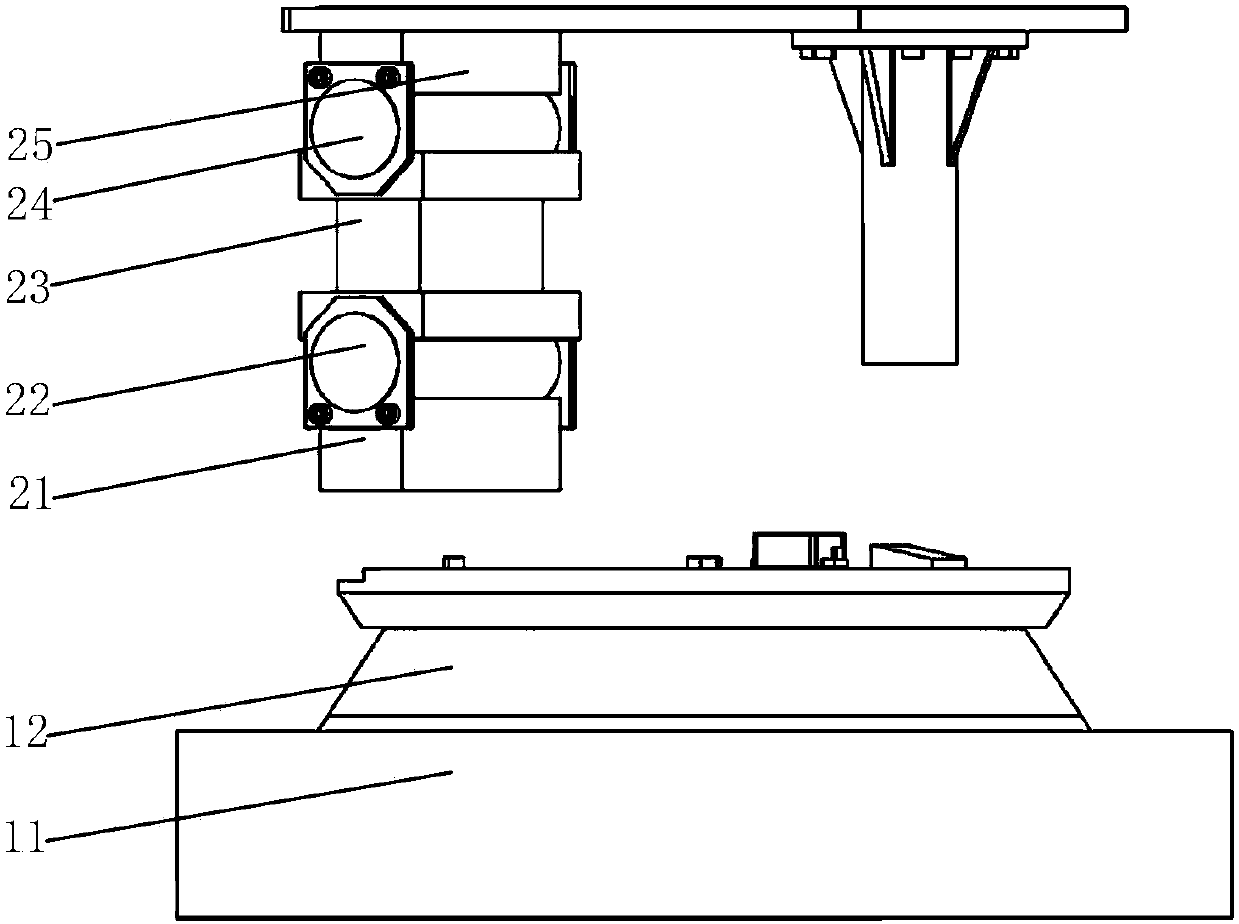

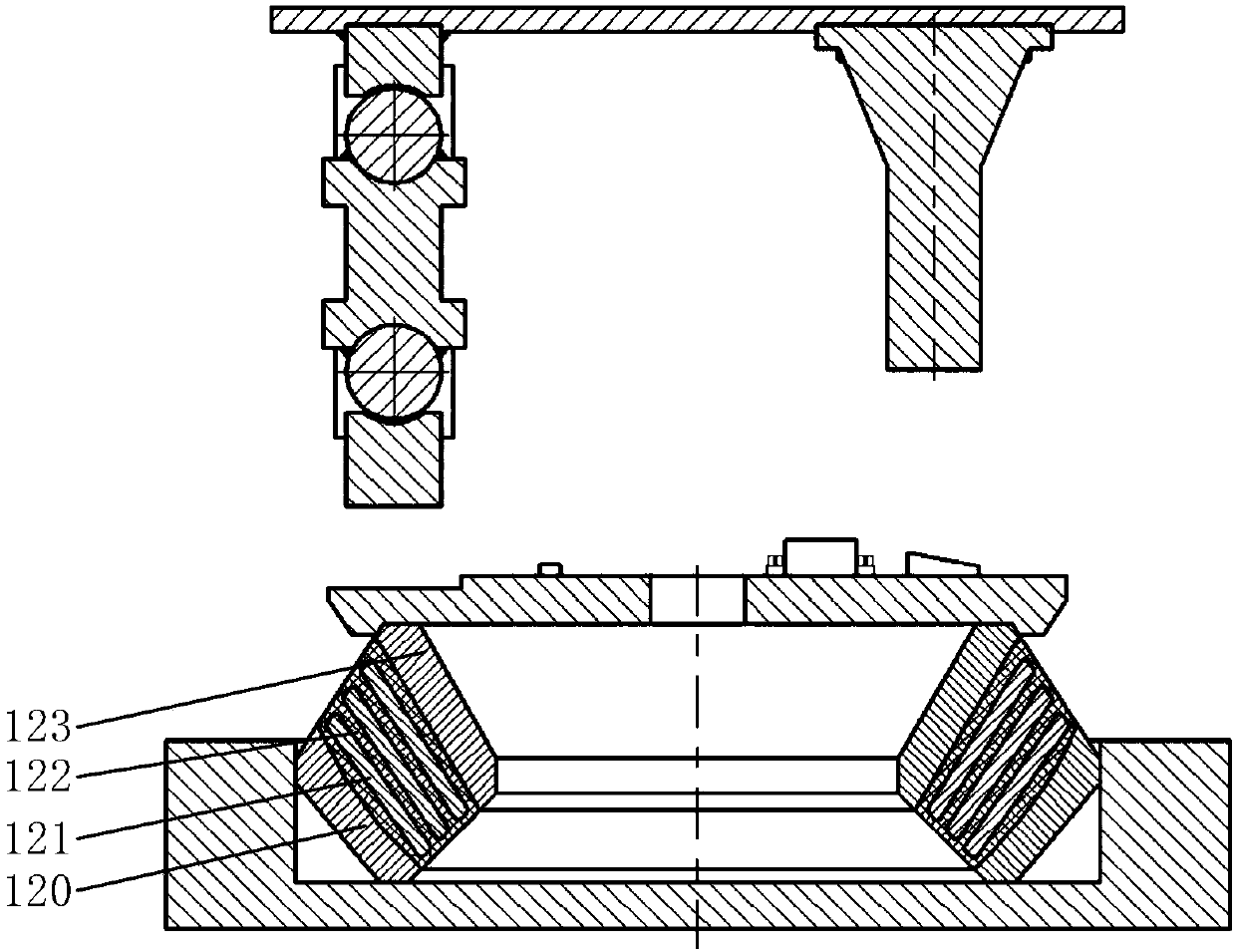

[0020] A test bench for testing the torsional stiffness of a flexible body according to the present invention includes a base part, a loading device and a limiting device, wherein the base part includes a base 11, a flexible body 12, a loading cover 14, and a loading cover located on the loading cover. The upper loading block slot 13, the angle sensor 15, and the cable outlet 16; the loading device includes a horizontally installed top plate 27, a loading block 21, a fixed block 25, a side plate 26, a force sensor 23, an upper shaft 24 and a lower shaft 25; The limiting device is composed of a group of limiting columns 31 and limiting blocks 32 . Both the top plate and the base of the test bench have flange threaded holes, which are respectively fixed on the upper and lower platforms of the pressure testing machine by screws. The lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com