Construction method for honeycomb-structured wave absorbing plate shrinkage ratio simulation material

A technology of honeycomb structure and scale simulation, which is applied in the field of target electromagnetic scattering characteristics test, and can solve problems such as difficult construction of scaled materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

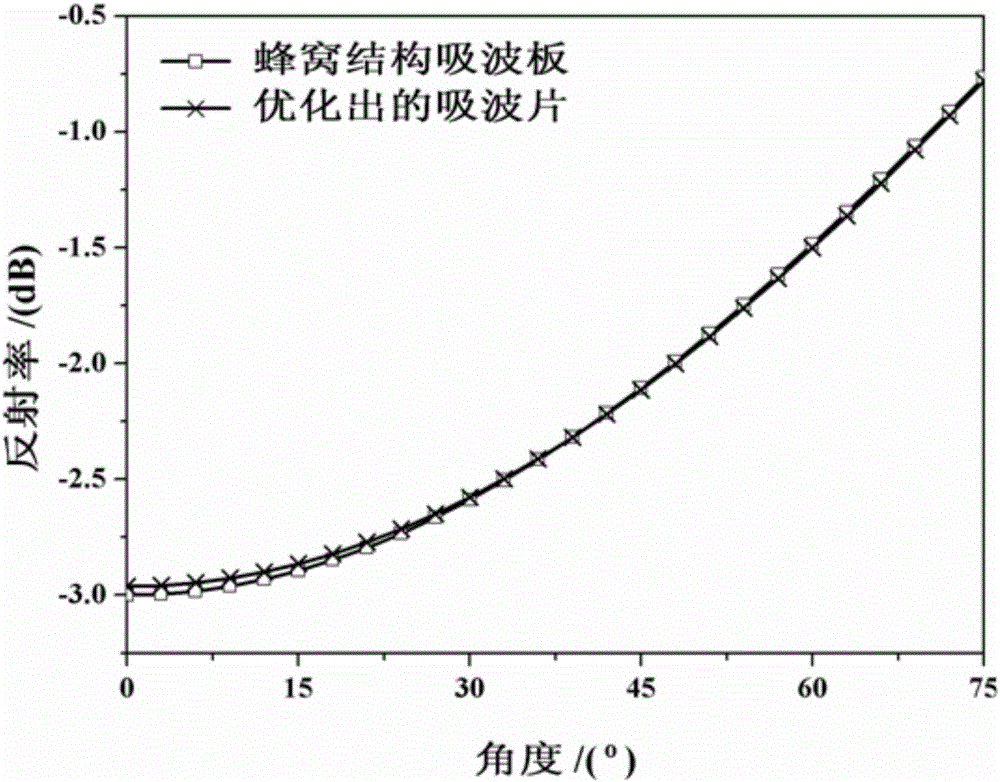

[0036] The honeycomb structure wave absorbing plate scaling simulation material construction method proposed by the present invention, its process mainly includes honeycomb structure wave absorbing plate reflectivity modeling and simulation, honeycomb structure wave absorbing plate scaling simulation material reflectivity optimization and honeycomb structure wave absorbing plate shrinkage There are three steps to simulate material construction, the specific process is as follows:

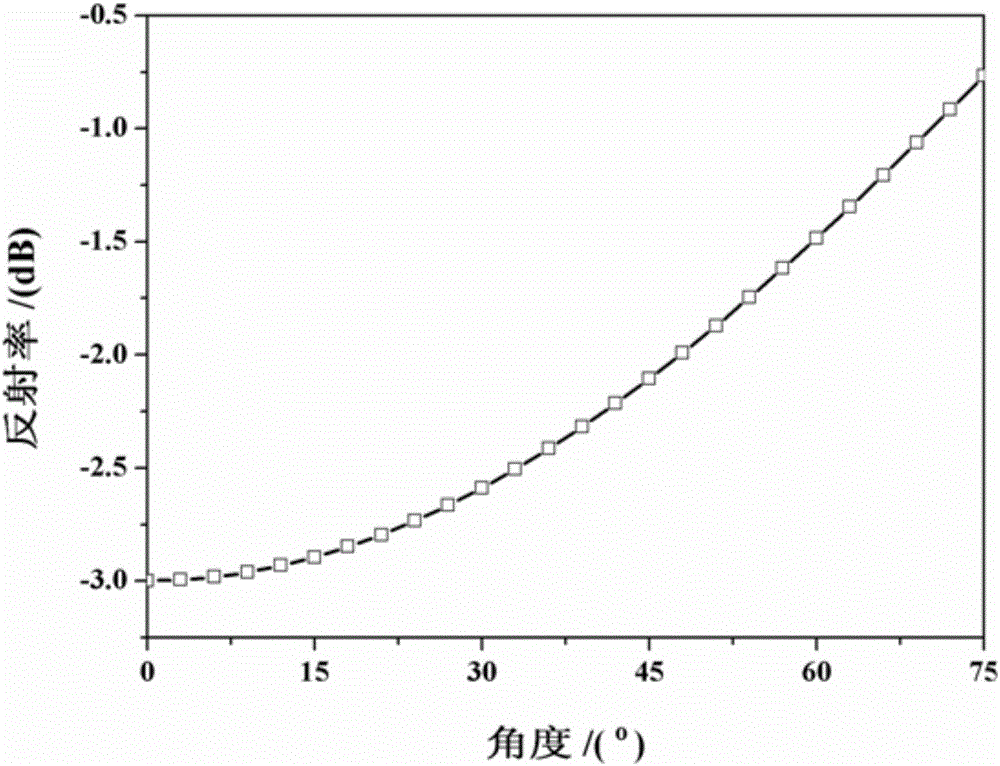

[0037] Step 1: Modeling and simulation of the reflectivity of the honeycomb structure absorbing plate

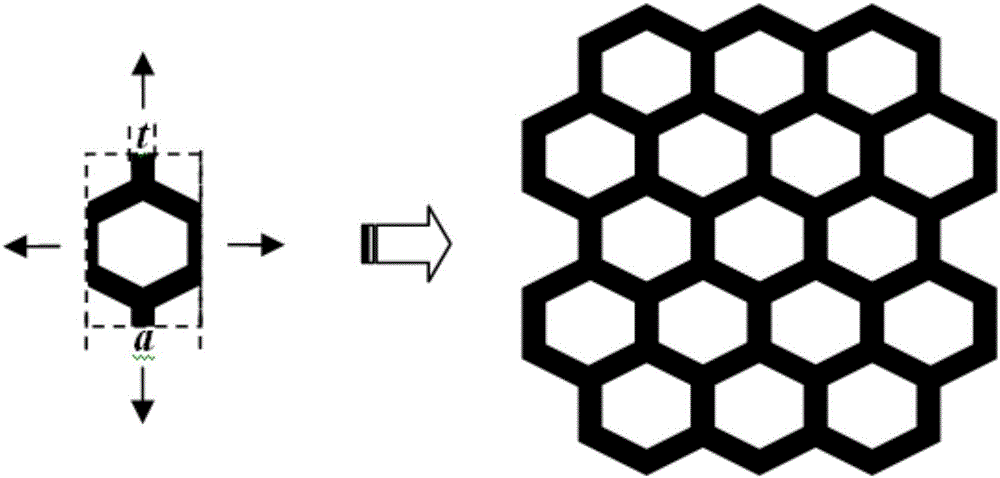

[0038] A typical honeycomb structure absorbing plate is formed by a periodic array of regular hexagonal carbonaceou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com