Delayed alarm device and PCBA surface mounting method

A technology of delay alarm and delay switch, applied in the direction of alarms, electrical components to assemble printed circuits, instruments, etc., can solve the problems of inability to transmit in time, slow operation, and scrapped PCBA residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

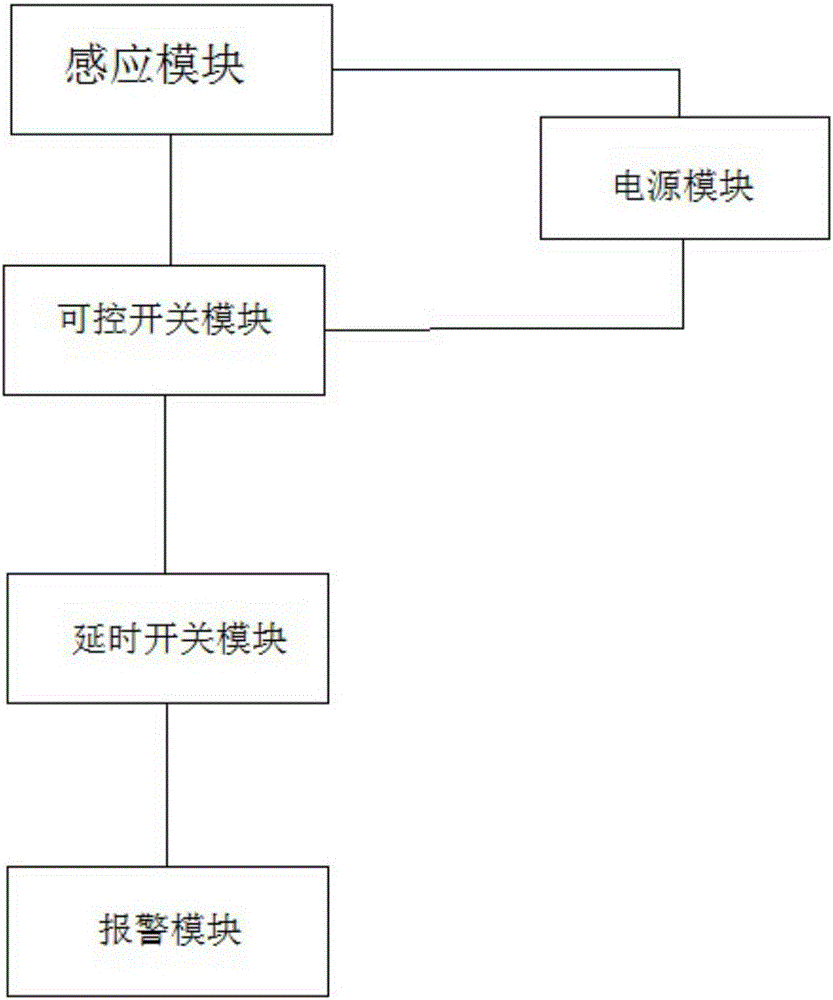

[0010] Embodiment 1 The controllable switch module adopts an electromagnetic relay, and the delay switch module adopts a delay switch with adjustable delay time. The parameters of the delay switch are: input voltage: DC24V; operating current is less than <50mA; output current : 1A, output voltage: equal to the input voltage, adjustable time range: 0-99 seconds. The induction module adopts a photoelectric sensor, and the Japanese Yamatake model is specifically selected as hp300-d1, the alarm module adopts a buzzer, and the power module adopts an AC / DC power module. The AC / DC power supply module is connected to 220v mains, outputs 24V, and is connected to the delay switch through the electromagnetic relay. When the photoelectric sensor senses that the PCBA board is stuck for a long time, the photoelectric sensor responds and outputs 24V voltage to the control terminal of the electromagnetic relay. , the switch terminal of the electromagnetic relay is turned on, thereby triggerin...

Embodiment 2

[0011] Embodiment 2, the controllable switch module adopts an electromagnetic relay, the delay switch module adopts a delay relay, and the induction module adopts a photoelectric sensor, specifically selects the Japanese Yamatake model as hp300-d1, and the alarm module adopts an indicator light, so The above power module adopts AC / DC power module. The AC / DC power supply module is connected to 220v mains, outputs 24V voltage, and is connected to the delay relay through the electromagnetic relay. When the photoelectric sensor senses that the PCBA board is stuck for a long time, the photoelectric sensor responds and outputs 24V voltage to the control terminal of the electromagnetic relay. , the switch end of the electromagnetic relay is turned on, thereby triggering the delay relay, and the delay relay starts counting down within the set time. When the timing reaches 00:00, the delay switch is turned on, and the indicator light alarms; After that, the photoelectric sensor stops o...

Embodiment 3

[0012] Embodiment 3 The PCBA surface mount method based on the time-delay alarm device, the method includes the process steps: use the cache equipment between the reflow furnace and the AOI detection equipment to connect back and forth to cache the PCBA, and the sensing module is fixed on the Between the reflow furnace and the cache device to sense whether the PCBA is stuck, when the PCBA is stuck, the sensing module responds, the sensing module outputs a control voltage to supply power to the controllable switch module, the controllable switch module is turned on, and the power module supplies the delay switch module power supply, the delay switch module is turned on according to the preset time, so that the alarm module starts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com