LED backlight drive circuit and liquid crystal display

A technology of backlight driving circuit and LED lamp, applied in static indicators, instruments, light sources, etc., can solve the hidden dangers of system safety, increase the manufacturing cost of driving chips, sparks and other problems, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

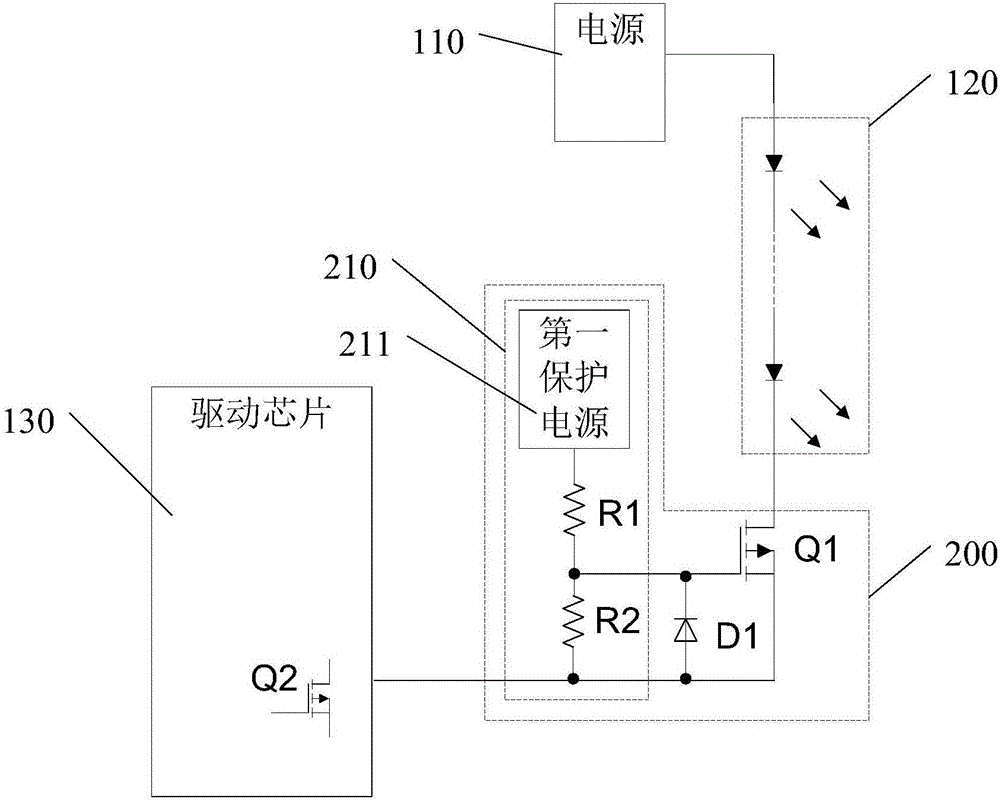

[0033] Please refer to figure 2 , is an LED backlight driving circuit provided in the first embodiment of the present invention, and the backlight driving circuit includes a power supply 110 , an LED string, a protection circuit and a driving chip 130 .

[0034] Specifically, the power supply 110 is used to provide power to the LED strings. The power supply 110 is, for example, a DC power output from other power supply circuits, or a DC power output from a power manager. The power supply provided in this embodiment 110 provides output voltages such as 36V (volts), 48V, 60V, 72V, etc., so as to drive LED strings.

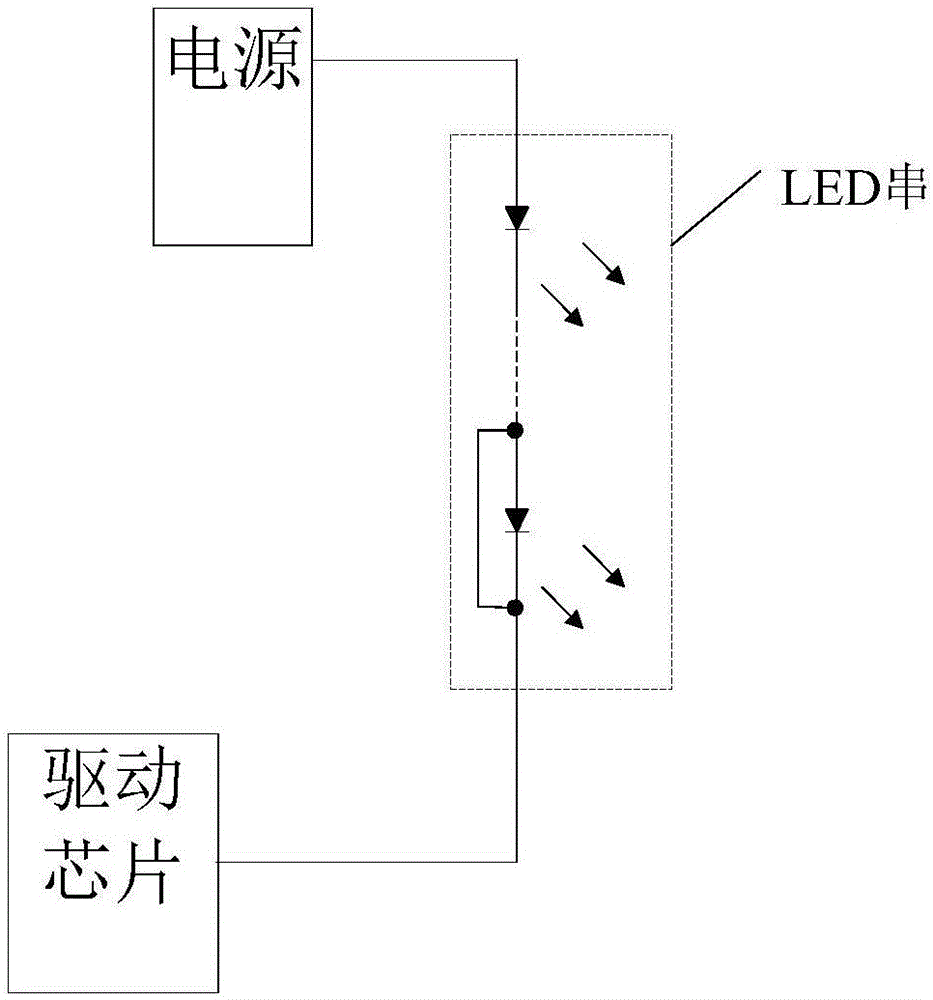

[0035] The LED string includes a plurality of LED lamps, the positive end of the LED string is electrically connected to the power supply 110, the number of LED lamps in the LED string can be determined according to needs, for example, 2 LED lamps, 4 LED lamps, 6 LED lights, 8 LED lights, 9 LED lights, 10 LED lights, etc., the LED lights in the LED string can be co...

no. 2 example

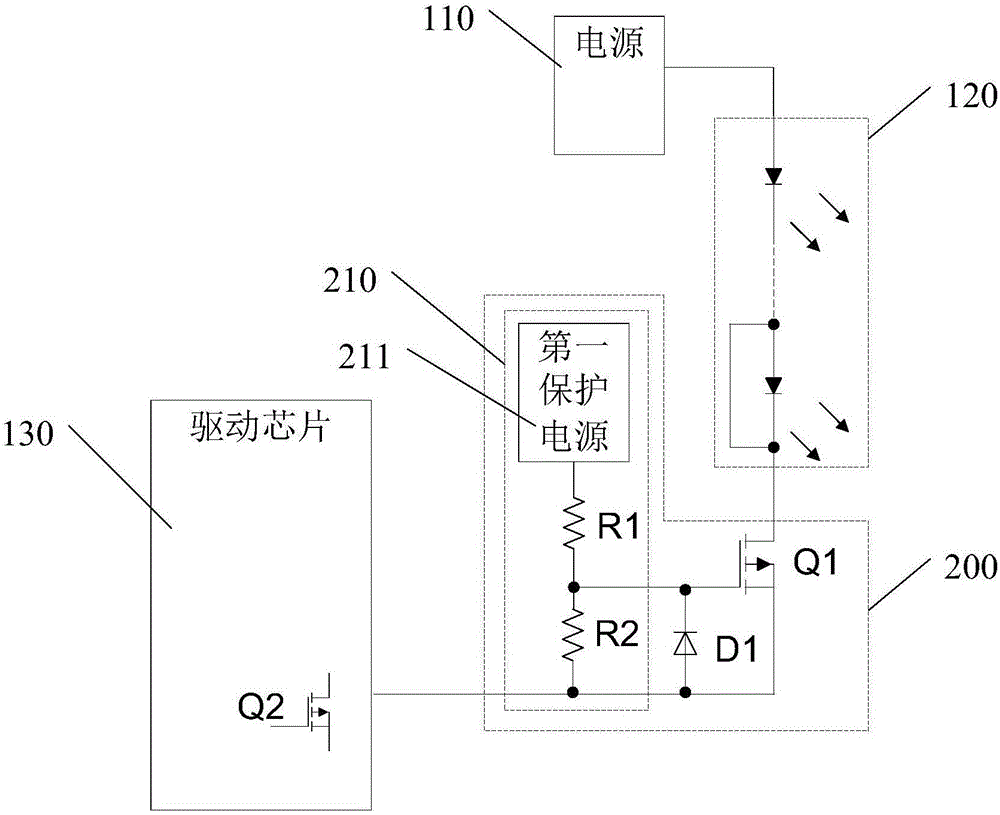

[0046] Figure 4 The LED backlight drive circuit provided by the second embodiment of the present invention, Figure 4 circuit with figure 2 The circuits are similar, so the same component symbols represent the same components. The main difference between this embodiment and the first embodiment is the LED string and the protection circuit.

[0047] See Figure 4 , the LED string further includes a second LED string 320, the second LED string 320 includes a plurality of LED lamps connected in series, and the first LED string 120 and the second LED string 320 are connected in parallel. The positive end of the second LED string 320 is electrically connected to the power supply 110; the protection circuit also includes a second protection circuit 400, one end of the second protection circuit 400 is electrically connected to the negative end of the second LED string 320, and the second protection circuit The other end of 400 is electrically connected to the second pin of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com