Full-automatic magnet ring winding machine

A wrap-around, fully automatic technology, applied in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low efficiency and high labor cost, reduce the limitation of manual proficiency, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention is described in further detail:

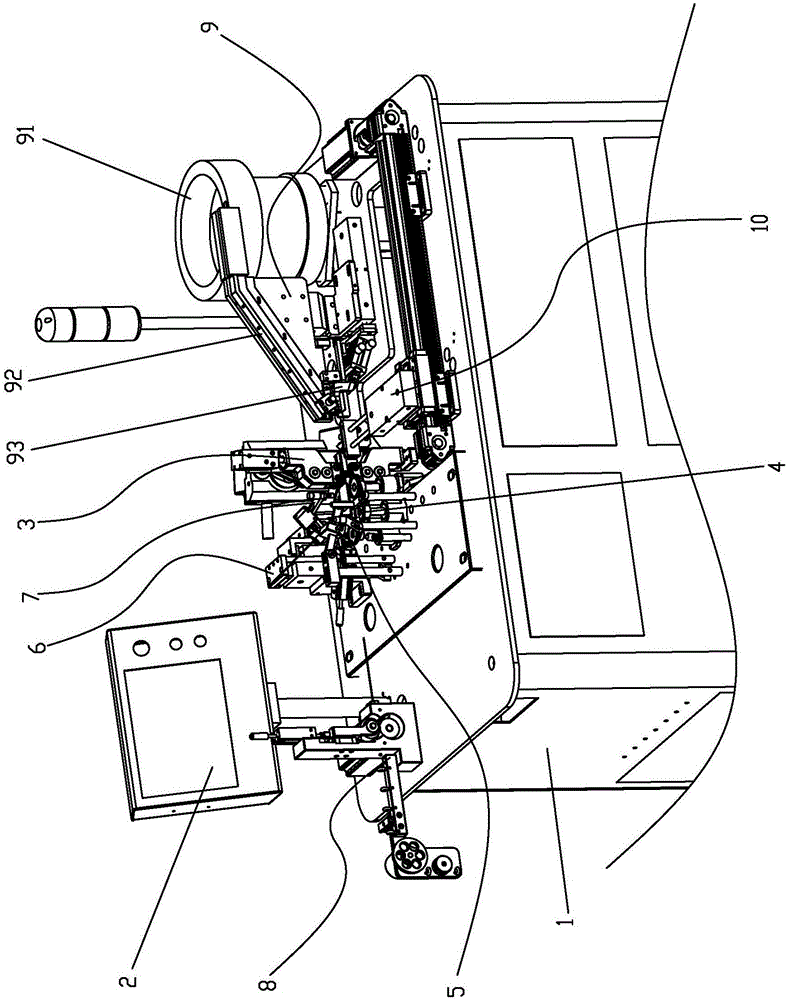

[0049] Such as Figure 1-17 As shown, a fully automatic magnetic winding machine, including:

[0050] Rack 1, used for installing various mechanisms;

[0051] A control device 2, which is arranged on the frame 1, is used to control the operation of various mechanisms / devices;

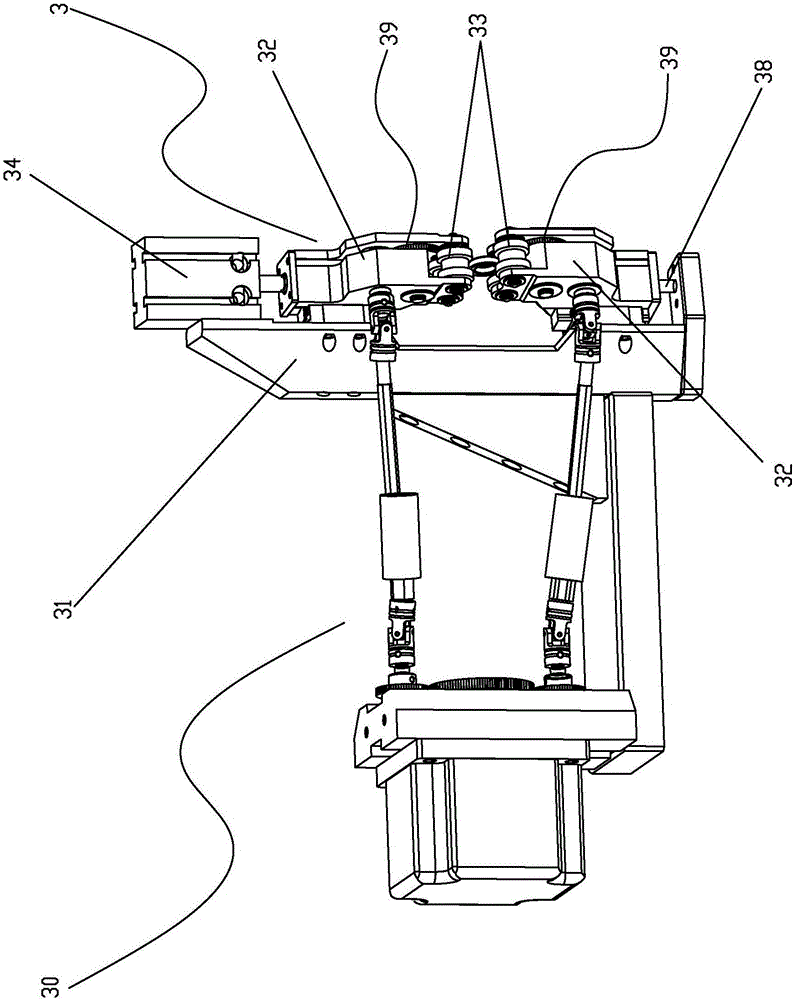

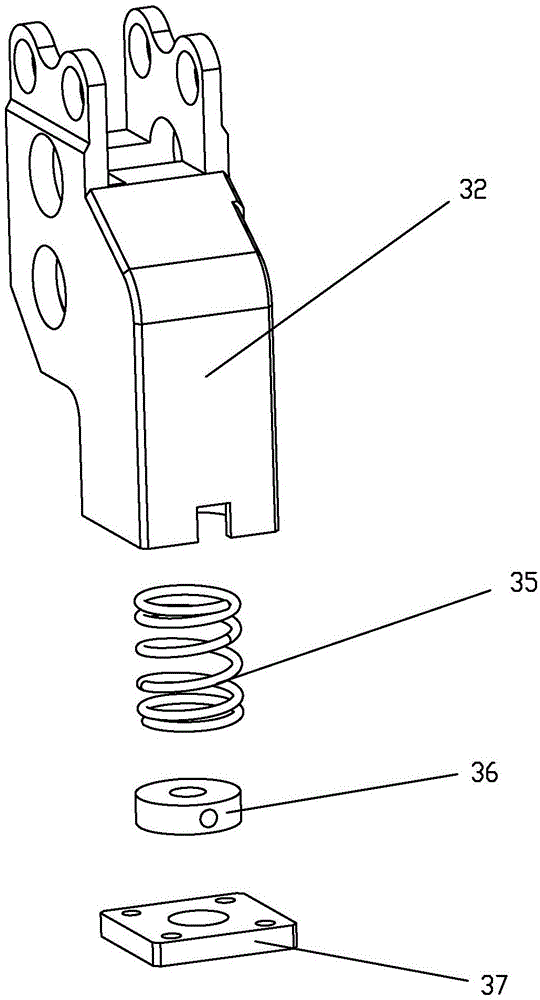

[0052] A clamping and arranging mechanism 3, which is arranged on the frame 1, and is used to clamp the magnetic ring and make it rotate and wind;

[0053] The winding mechanism includes a wire storage ring 4 with an open ring opening 41 and a driving device 5 that supports and drives the rotation of the wire storage ring 4. The wire storage ring 4 is provided with a side slider 42 and a wire storage hanging port 43, The frame 1 is provided with a wire hanging device 6 for wire storage in the wire storage ring 4 and wire hanging during winding;

[0054] Detection and positioning mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com