Wafer transfer device

A technology for transferring devices and wafers, used in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc. The effect of low intensity and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

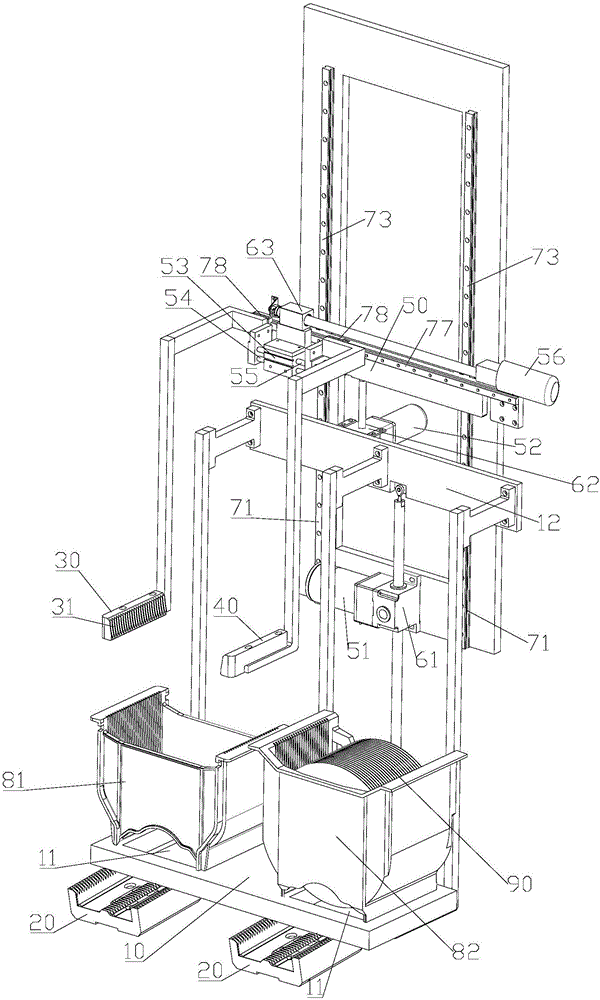

[0029] Such as figure 1 , a wafer transfer device, which includes a support table 10 , a tray 20 , a first robot arm 30 and a second robot arm 40 . The supporting platform 10 is provided with a plurality of through holes 11 . A plurality of through holes 11 are arranged at intervals. The supporting platform 10 is arranged on the bracket 12 . The bracket 12 can carry the supporting platform 10 and is set up and down. The first rotating motor 51 is connected to the first lead screw nut 61 , and the bracket 12 is connected to the first lead screw nut 61 . The first rotating motor 51 drives the bracket 12 to lift up and down through the first lead screw nut 61 . First sliders (not shown in the figure) are respectively arranged on the two first guide rails 71 . The first slider can lift and slide along the first guide rail 71 . The bracket 12 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com