A quantum dot solid film with continuously changing energy level barrier height and its preparation method

A barrier height and quantum dot technology, applied in the field of quantum dots, can solve problems such as poor device performance, inability to regulate the injection barrier of electrons and holes, change the energy level barrier height of quantum dot solid film, and achieve improved Recombination probability, effect of improving device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

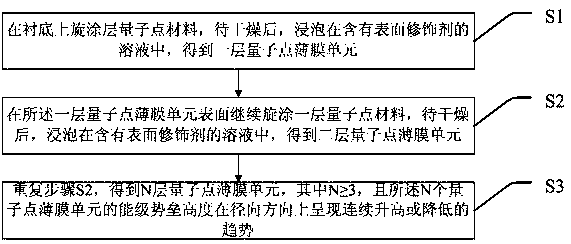

Method used

Image

Examples

Embodiment 1

[0043] Quantum dot solid films with continuously increasing barrier heights were prepared with red quantum dots CdSe, bromide (TBABr), 1,3-benzenedithiol (1,3-BDT), and thiophenol (BT):

[0044] 1. The preparation of oil-soluble CdSe quantum dots is as follows:

[0045] 1) Cadmium oleate {Cd(OA) 2}Precursor preparation:

[0046] Add 2 mmol of cadmium oxide (CdO), 3 ml of oleic acid (OA), and 10 ml of octadecene (ODE) into a three-necked flask. First, vacuumize at room temperature for 30 mins, then heat to 180°C and exhaust argon for 60 mins, and then maintain it for 180 °C. ℃ vacuumize for 30 mins, cool to room temperature for later use;

[0047] 2) Preparation of Selenium (Se) Precursor:

[0048] Add 4mmol of Se to 4ml of trioctylphosphine (TOP), heat to 170°C for 30min, then cool down to 140°C.

[0049] 3) Preparation of red CdSe quantum dots:

[0050] The cadmium oleate {Cd(OA) in 1) 2} The precursor was heated to 280°C, and then 2ml of selenium (Se) precursor was ext...

Embodiment 2

[0065] Red quantum dots CdSe, ethylenediamine (EDA), ethanedithiol (EDT), ammonium thiocyanate (NH 4 SHN) to prepare quantum dot solid films with continuously reduced barrier heights:

[0066] 1. The preparation of oil-soluble CdSe quantum dots is as follows:

[0067] 1) Cadmium oleate {Cd(OA) 2}Precursor preparation:

[0068] Add 2 mmol of cadmium oxide (CdO), 3 ml of oleic acid (OA), and 10 ml of octadecene (ODE) into a three-necked flask. First, vacuumize at room temperature for 30 mins, then heat to 180°C and exhaust argon for 60 mins, and then maintain it for 180 °C. ℃ vacuumize for 30 mins, cool to room temperature for later use;

[0069] 2) Preparation of Selenium (Se) Precursor:

[0070] Add 4mmol of Se to 4ml of trioctylphosphine (TOP), heat to 170°C for 30min, then cool down to 140°C.

[0071] 3) Preparation of red CdSe quantum dots:

[0072] The cadmium oleate {Cd(OA) in 1) 2} The precursor was heated to 280°C, and then 2ml of selenium (Se) precursor was extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com