Lightweight battery box based on lattice structure

A lattice structure, lightweight technology, applied in batteries, structural parts, secondary batteries, etc., can solve the problem of increasing the weight of electric vehicles, and achieve the effects of minimizing material consumption, saving costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

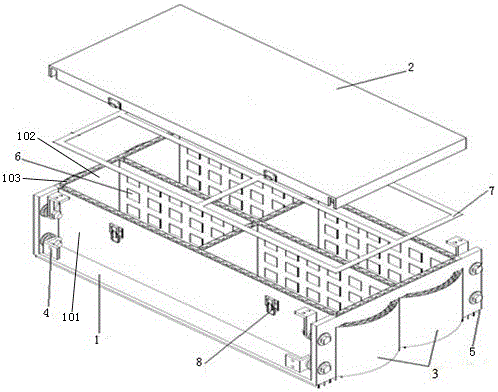

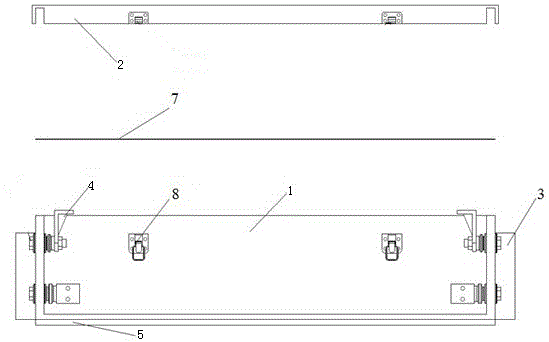

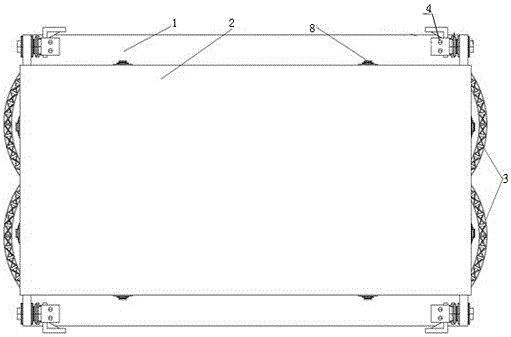

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings of this example, so that the technical solution of the present invention can be easily understood and mastered.

[0021] Such as figure 1 , figure 2 , image 3 As shown, a lightweight battery box based on a lattice structure, including a box body 1 and a box cover 2, two parallel arched anti-collision buffer beams 3 are arranged on the front and rear ends of the box body 1, and the arched anti-collision buffer beams 3 is fixed on the box body 1 by means of bolt connection; there are multiple semi-suspended connecting plates 4 on the left and right sides of the box body 1, that is, there is a semi-suspended connecting plate 4 at the four corners of each side of the box body 1 Connecting plate; the extended end of the semi-suspended connecting plate is provided with a connecting hole, and its inner end is connected with the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com