Rotor of ultrahigh-speed asynchronous motor

An asynchronous motor, ultra-high-speed technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of expensive processing, complex processing of solid rotor structure, poor electrical performance, etc., to achieve low manufacturing cost, The effect of low structural complexity and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

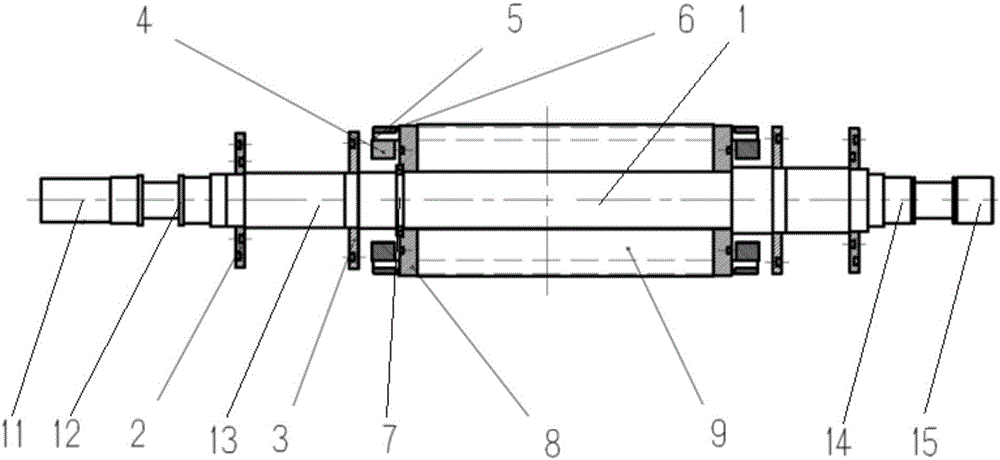

[0017] see figure 1 , a rotor of an ultra-high-speed asynchronous motor of the present invention includes a rotating shaft 1 and an iron core 9 sleeved on the rotating shaft 1 .

[0018] The rotating shaft 1 is divided into a driving end 11 , a driving end connecting section 12 , an iron core connecting section 13 , a non-driving end connecting section 14 and a non-driving end 15 , which are connected in sequence. The iron core 9 is shrink-fitted in the middle of the iron core connection section 13 . The iron core 9 and the iron core connecting section 13 adopt a large interference fit in the radial direction, so that the connection strength is sufficient to overcome the centrifugal force generated by the rotor under high-speed rotation; the end of the iron core 9 close to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com