Apparatus and method for measuring surface topography optically

A technology of surface topography and light beams, applied in the direction of optical devices, measuring devices, optical sensors, etc., can solve problems such as difficult control and inaccurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

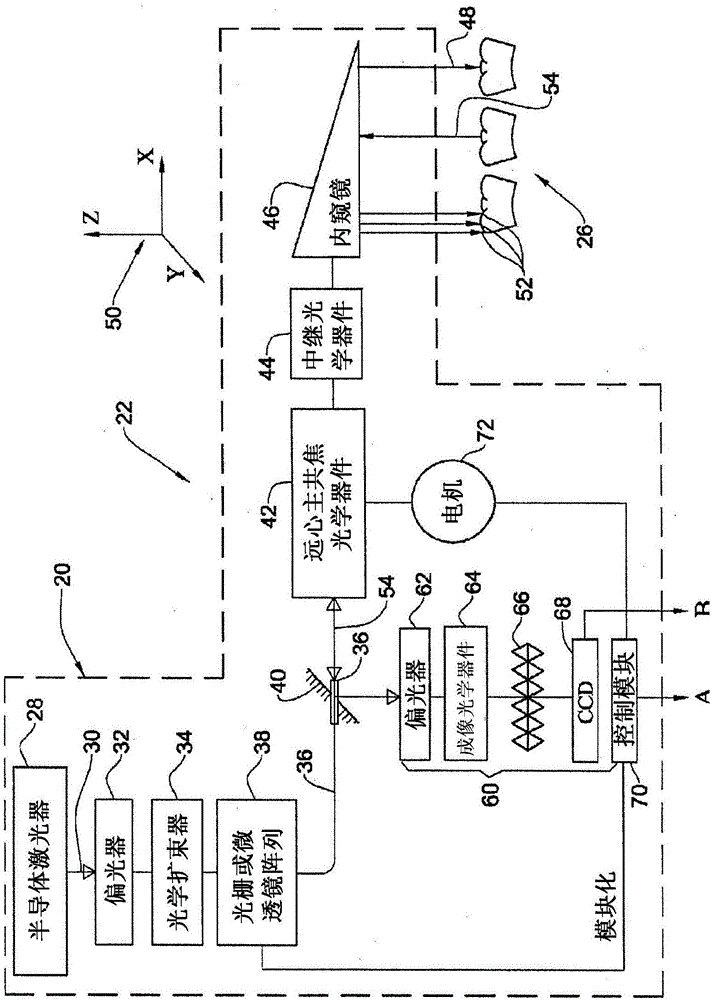

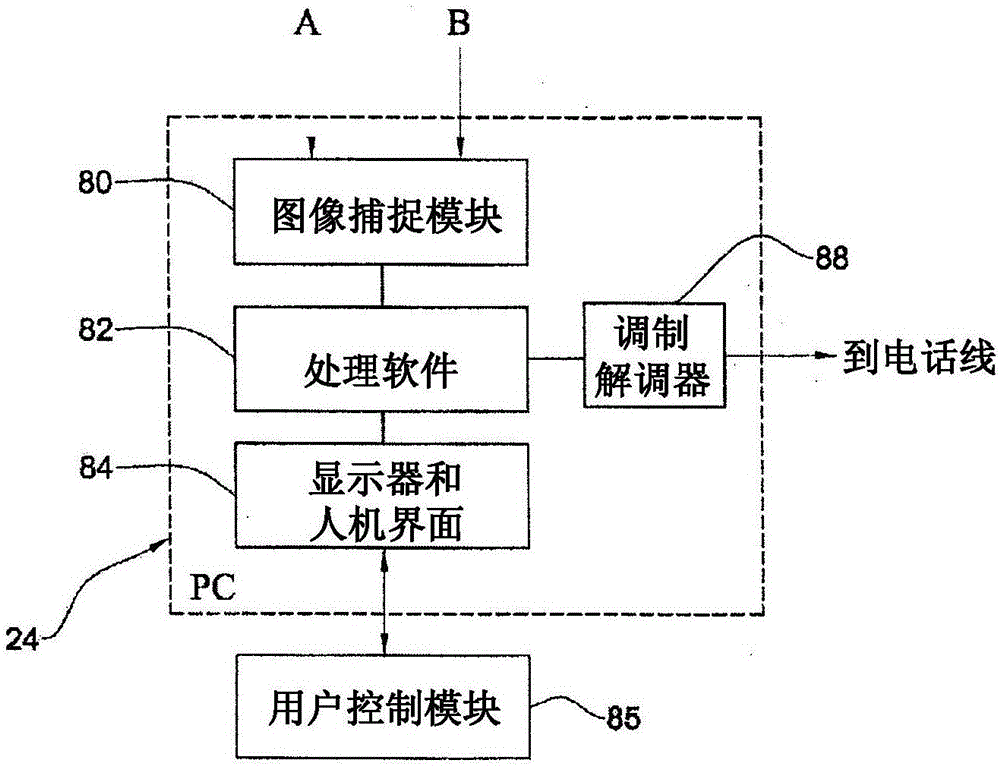

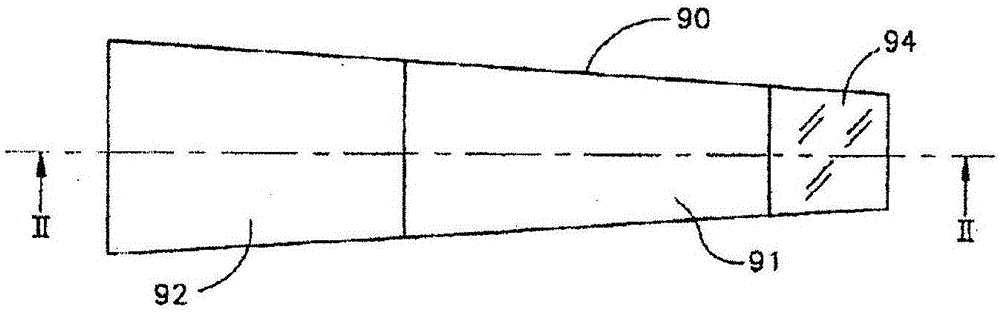

[0024] In many embodiments, an apparatus for optically determining surface topography includes a light focusing assembly configured to controllably alter the intensity of a light beam projected toward a three-dimensional structure being measured (e.g., a patient's dentition). depth of focus. Compared to traditional methods that employ a large amount of movement of the light focusing assembly, the light focusing assembly disclosed herein utilizes less, if any, moving parts and is therefore smaller, faster and more compact. Furthermore, the apparatus and methods disclosed herein for optically determining surface topography can be used to vary the depth of focus of a light beam while maintaining telecentricity. Telecentric optics produce a constant image magnification independent of the object distance within a defined telecentric range and, therefore, can advantageously be used to increase the accuracy of the optical measurement system.

[0025] The devices and methods describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com