Sensor arrangement for the contactless sensing of angles of rotation on a rotating part

A sensor assembly, a technology for detecting rotation, which is used in converting sensor output, using electromagnetic/magnetic devices to transmit the direction of sensing components, instruments, etc., can solve the problem that the evaluation of the coupling coefficient requires expensive electronic equipment, etc. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

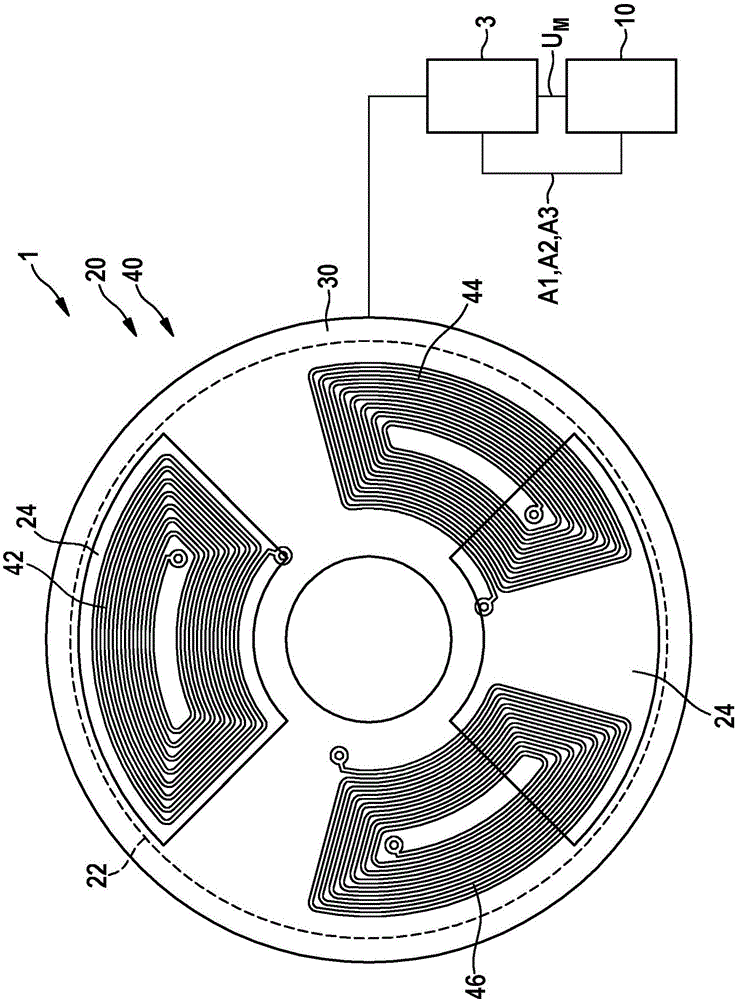

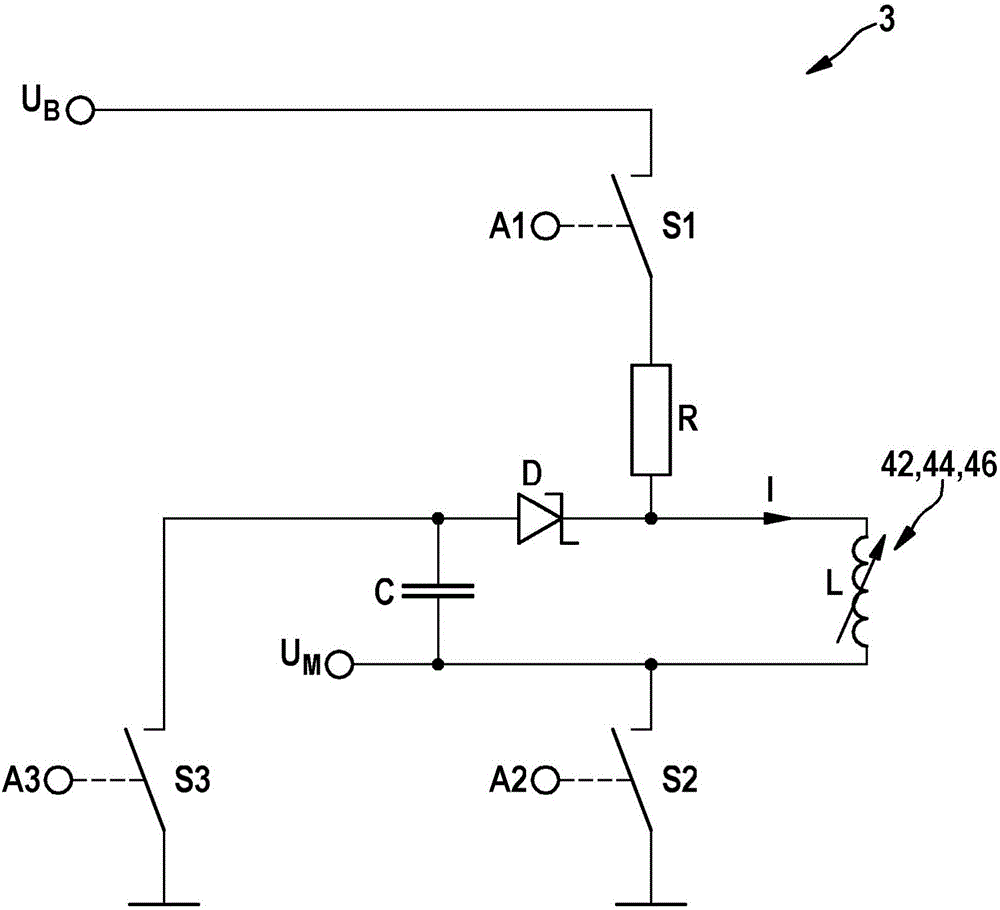

[0016] as by figure 1 and figure 2 As can be seen, the illustrated embodiment of the sensor assembly 1 according to the invention for the contactless detection of the angle of rotation of a rotary component comprises a target 20 coupled to the rotary component, which has an annular disk-shaped base body 22 , the base body has at least one metal surface 24 ; and a coil assembly 40 with at least one planar detection coil 42 , 44 , 46 arranged on a circular circuit board 30 . Obviously, the circuit board 30 does not have to be circular, and the circuit board 30 can also have other suitable shapes. The target object 20 combines with the coil assembly 40 to generate at least one kind of information for determining the current rotation angle of the rotating component. According to the invention, at least one measuring circuit 3 converts the inductance L of the corresponding planar search coil 42 , 44 , 46 into a measuring signal U M The inductance changes due to the eddy current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com