Quality monitoring in a packaging line

A packaging line and monitoring system technology, applied in logistics, program control, measuring devices, etc., can solve the problem of packaging lines that cannot use a large amount of accumulated data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

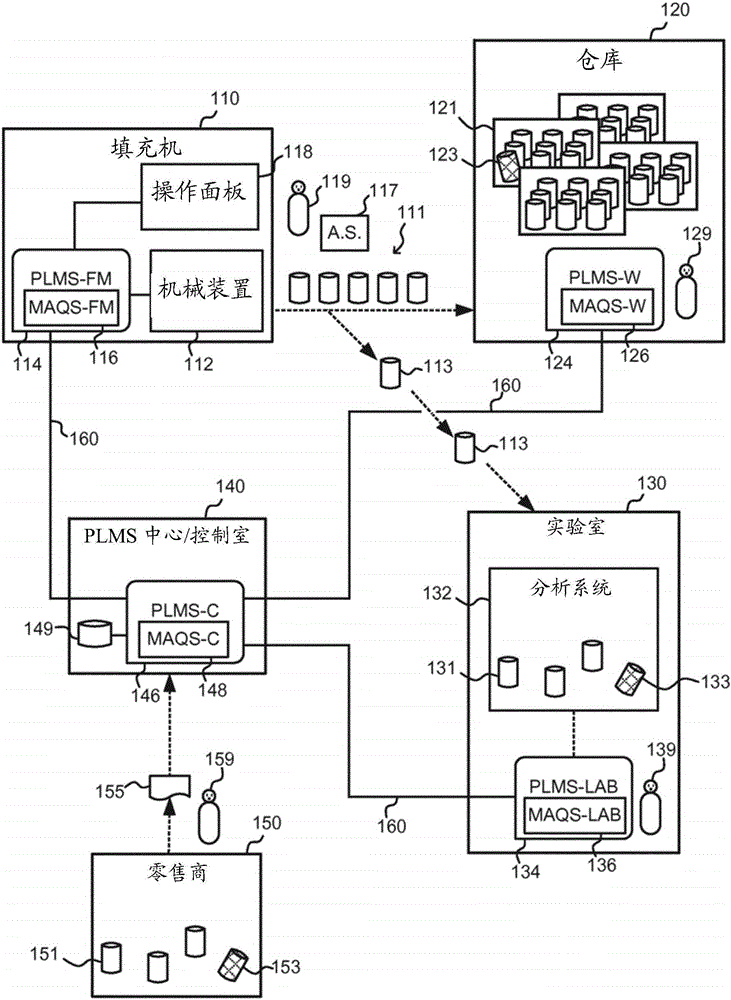

[0024] figure 1 Shown is a filling machine FM 110 configured to output packages 111 filled with food products. FM 110 includes a large number of components and subsystems. However, not all of these are necessary to describe the disclosure in detail, as one skilled in the art will readily understand how to practice the embodiments described herein without such details. FM 110 includes mechanical device 112 , FM control system 114 and operator panel 118 . As the skilled artisan will appreciate, the machinery 112 typically includes package handling and filling devices suitable for filling packages with food products. The operation panel 118 typically includes a graphical display and various input devices such as soft buttons and the like. An operator 119 interacts with the FM 110 via an operation panel 118 . The operator 119 may be a human operator who then interacts via the operator panel 118, but in some implementations it is envisioned that the operator 119 is generally an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com