Header for paper mulberry tree ensilaging and direct harvesting bundling machine

A technology for balers and headers, applied in headers, harvesters, applications, etc., can solve problems such as difficult harvesting and transportation, and hard mulberry stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

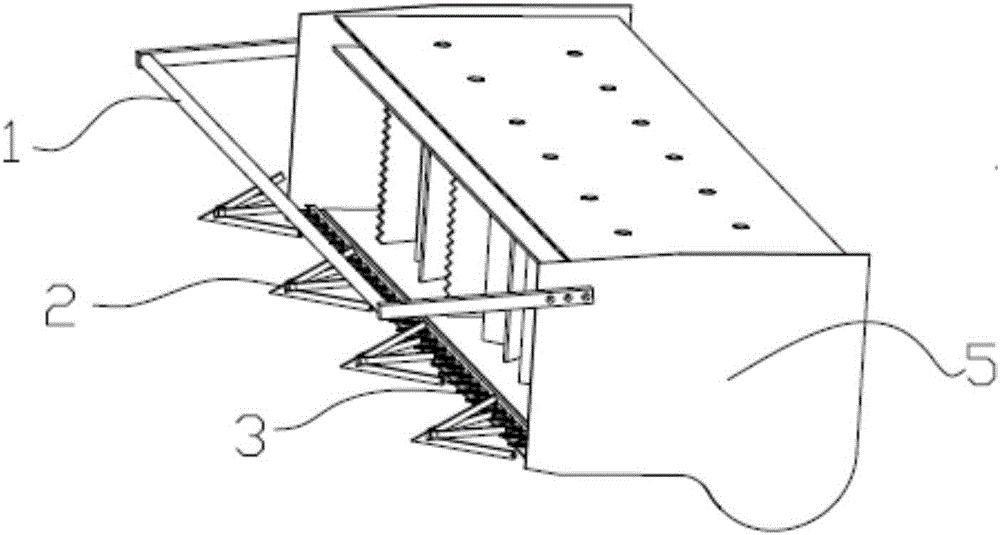

[0026] Combine below Figure 1-Figure 7 Specific embodiments of the present invention are described in detail:

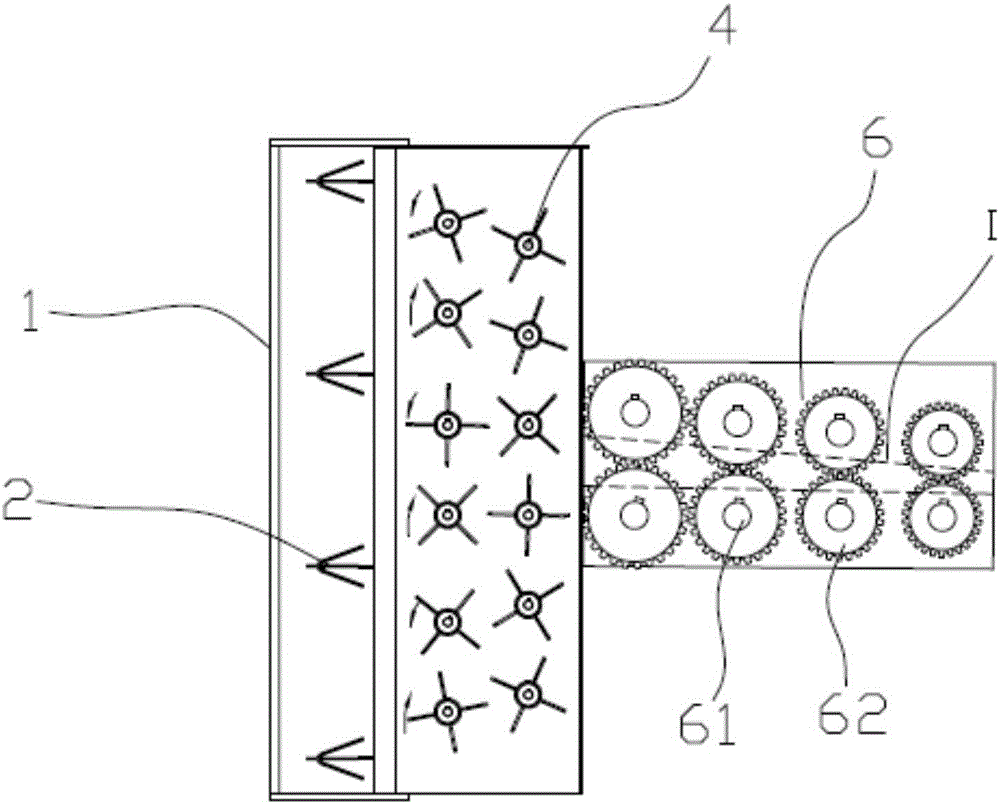

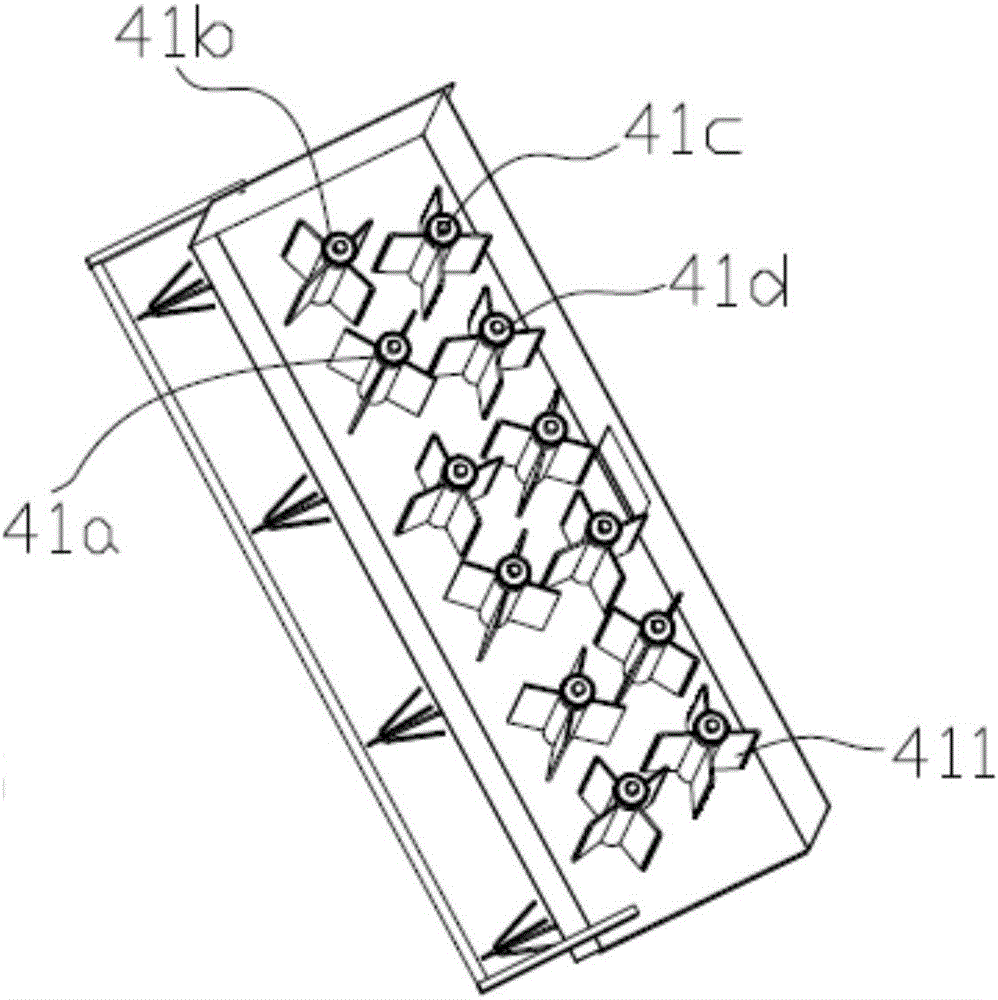

[0027] The present invention comprises knockdown device 1, crop divider 2, cutter assembly 3, feeding wheel assembly 4, box body 5 and bridge assembly 6.

[0028] Described push down device 1 is the cross bar that is arranged on the front upper end of described box body 5, and the fixed bar that stretches out is fixed on both sides of box body 5, and cross bar is fixed on the described fixed bar.

[0029] The grain divider 2 is located at the front lower end of the casing 5 . In order to adapt to the messy and hard branches of the mulberry tree, the crop divider 2 includes four sub-claws extending backward from the front tip, up and down, left and right, so that the mulberry branches can be fully sorted and picked up.

[0030] The cutter assembly 3 is located at the front lower end of the casing 5 and behind the crop divider 2, and the cutter assembly 3 adopts a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com