Electronic tube display protection device for electronic component

A technology for electronic components and protection devices, which is applied to the field of electronic tube display protection devices for electronic components, can solve the problems of wasting raw materials, economic losses, increasing electronic tubes, etc., and achieves the effect of neat appearance and reduced sales volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

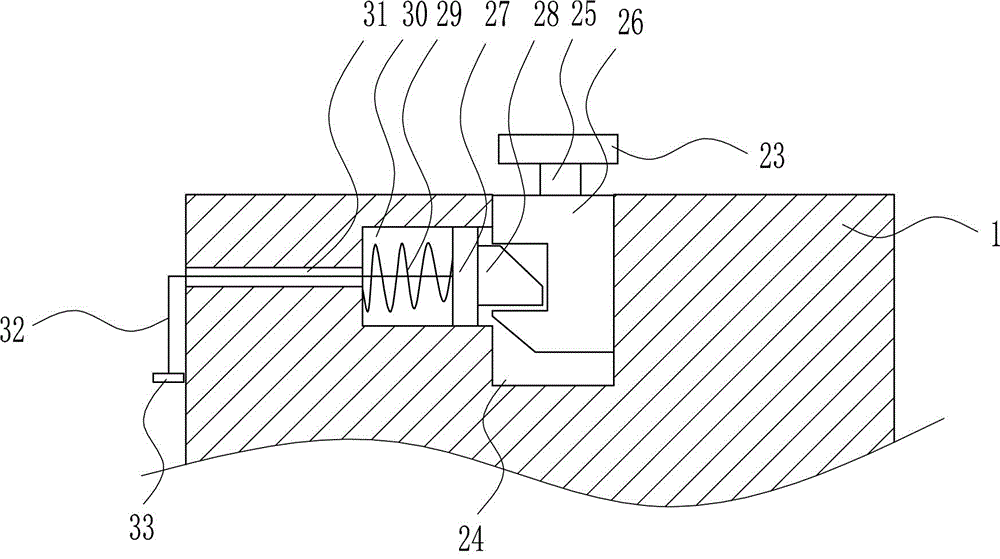

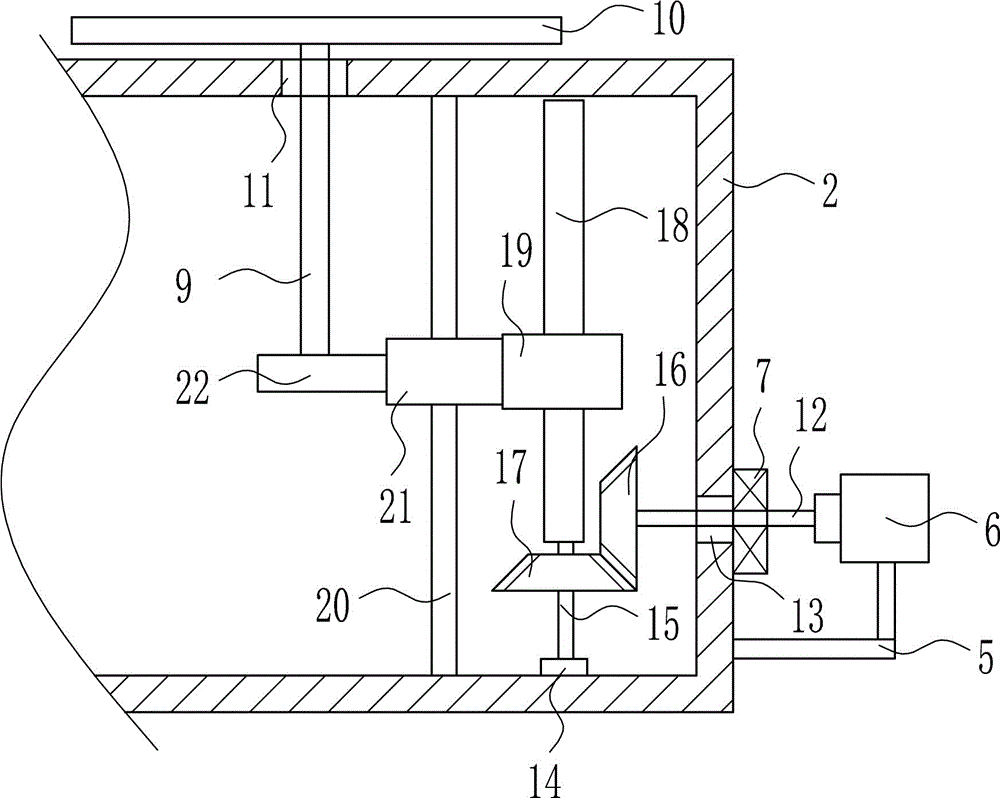

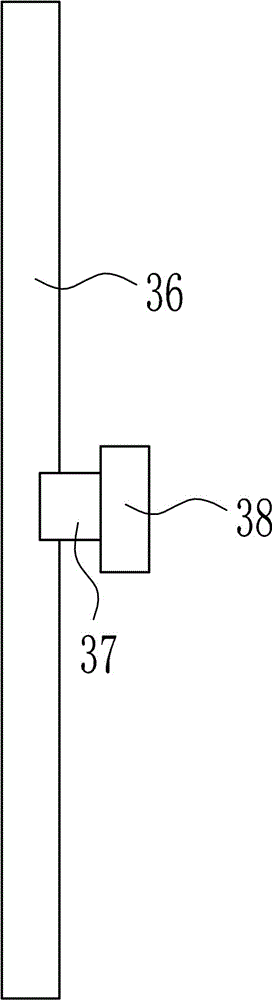

[0036] An electronic tube display protection device for electronic components, such as Figure 1-9 As shown, it includes a display table 1, a cabinet body 2, a partition 4, a bracket 5, a motor 6, a first bearing seat 7, a connecting rod 9, a placement plate 10, a first rotating shaft 12, a second bearing seat 14, a second Rotating shaft 15, first bevel gear 16, second bevel gear 17, screw rod 18, nut 19, slide bar 20, first slider 21 and fixed plate 22, the left side of display table 1 has through groove 3, through groove 3 The display table 1 in the middle is connected with a partition plate 4 by means of bolt connection, the right side of the display table 1 is connected with a cabinet body 2 by a method of bolt connection, and the lower part of the right side outside the cabinet body 2 is connected by a method of bolt connection. Bracket 5, the top of the bracket 5 is connected with the motor 6 by bolt connection, the right side outside the cabinet body 2 is connected with...

Embodiment 2

[0038] An electronic tube display protection device for electronic components, such as Figure 1-9 As shown, it includes a display table 1, a cabinet body 2, a partition 4, a bracket 5, a motor 6, a first bearing seat 7, a connecting rod 9, a placement plate 10, a first rotating shaft 12, a second bearing seat 14, a second Rotating shaft 15, first bevel gear 16, second bevel gear 17, screw rod 18, nut 19, slide bar 20, first slider 21 and fixed plate 22, the left side of display table 1 has through groove 3, through groove 3 The display table 1 in the middle is connected with a partition plate 4 by means of bolt connection, the right side of the display table 1 is connected with a cabinet body 2 by a method of bolt connection, and the lower part of the right side outside the cabinet body 2 is connected by a method of bolt connection. Bracket 5, the top of the bracket 5 is connected with the motor 6 by bolt connection, the right side outside the cabinet body 2 is connected with...

Embodiment 3

[0041] An electronic tube display protection device for electronic components, such as Figure 1-9 As shown, it includes a display table 1, a cabinet body 2, a partition 4, a bracket 5, a motor 6, a first bearing seat 7, a connecting rod 9, a placement plate 10, a first rotating shaft 12, a second bearing seat 14, a second Rotating shaft 15, first bevel gear 16, second bevel gear 17, screw rod 18, nut 19, slide bar 20, first slider 21 and fixed plate 22, the left side of display table 1 has through groove 3, through groove 3 The display table 1 in the middle is connected with a partition plate 4 by means of bolt connection, the right side of the display table 1 is connected with a cabinet body 2 by a method of bolt connection, and the lower part of the right side outside the cabinet body 2 is connected by a method of bolt connection. Bracket 5, the top of the bracket 5 is connected with the motor 6 by bolt connection, the right side outside the cabinet body 2 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com