Production method of high-quality roasted eel fillets

A technology of Kabayaki eel and production method, which is applied in the direction of meat/fish preservation, food ingredients as antimicrobial preservation, food preservation, etc., which can solve the problem of increasing production and sales costs, not having a soft and delicate taste, and reducing the quality of grilled eel products to reduce sales, retain protein content and amino acid composition, and improve sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

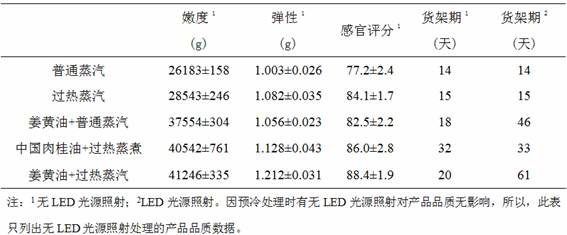

Embodiment 1

[0042]Check and accept live river eels with a growth cycle of one year and no disease, and then raise them in water for 24 hours. Chill the eel until dizzy, remove the head and kill it, cut it into upper and lower pieces along the abdomen, wash it with clean water to remove blood and internal organs; put the slaughtered eel slices in warm water at 78 ℃ for 30 seconds, and then put them in a vacuum In the dipping kettle, inject the dipping liquid (the dipping liquid consists of 0.35 parts of table salt, 5 parts of vinegar, 6 parts of cooking wine, 3 parts of ginger garlic water, 1 part of pepper powder, 1 part of cumin powder, 1.5 parts of light soy sauce, 1.5 parts of white sugar mixed parts), close the valve, adjust the vacuum degree to -0.06 MPa, and soak for 15 minutes; then the dipped eel slices are cured for 4 minutes with superheated steam containing 0.5mL / L turmeric oil at 280 ℃, and then the eel slices Place the skin side down and the meat side up. The leather side is ...

Embodiment 2

[0044] Check and accept live river eels with a growth cycle of one year and no disease, and then raise them in water for 24 hours. Chill the eel until dizzy, remove the head and kill it, cut it into upper and lower pieces along the abdomen, wash it with clean water to remove blood and internal organs; put the slaughtered eel slices in warm water at 78 ℃ for 30 seconds, and then put them in a vacuum In the dipping kettle, inject the dipping liquid (the dipping liquid consists of 0.35 parts of table salt, 5 parts of vinegar, 6 parts of cooking wine, 3 parts of ginger garlic water, 1 part of pepper powder, 1 part of cumin powder, 1.5 parts of light soy sauce, 1.5 parts of white sugar made by mixing parts), close the valve, adjust the vacuum degree to -0.06 MPa, and soak for 15 minutes; then, the soaked eel slices are cured for 6 minutes with superheated steam containing 1.0mL / L turmeric oil at 260 °C, and then the eel slices Place the skin side down and the meat side up. The leat...

Embodiment 3

[0046] Check and accept the moray eels with a growth cycle of one year and no disease, and then raise them in water for 24 hours. Chill the eel until dizzy, remove the head and kill it, cut it into upper and lower pieces along the abdomen, wash it with clean water to remove blood and internal organs; put the slaughtered eel slices in warm water at 78 ℃ for 30 seconds, and then put them in a vacuum In the dipping kettle, inject the dipping liquid (the dipping liquid consists of 0.35 parts of table salt, 5 parts of vinegar, 6 parts of cooking wine, 3 parts of ginger garlic water, 1 part of pepper powder, 1 part of cumin powder, 1.5 parts of light soy sauce, 1.5 parts of white sugar made by mixing parts), close the valve, adjust the vacuum degree to -0.06 MPa, and soak for 15 minutes; then, the soaked eel slices are cured for 5 minutes with superheated steam containing 1.0mL / L turmeric oil at 270 ℃, and then the eel slices Place the skin side down and the meat side up. The leathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com