Near-field direct-writing device based on composite receiving plate

A receiving board and near-field technology, applied in processing platforms/substrates, manufacturing tools, additive manufacturing, etc., can solve problems such as uneven fiber arrangement, achieve the effect of solving uneven distribution and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] Specific embodiment one

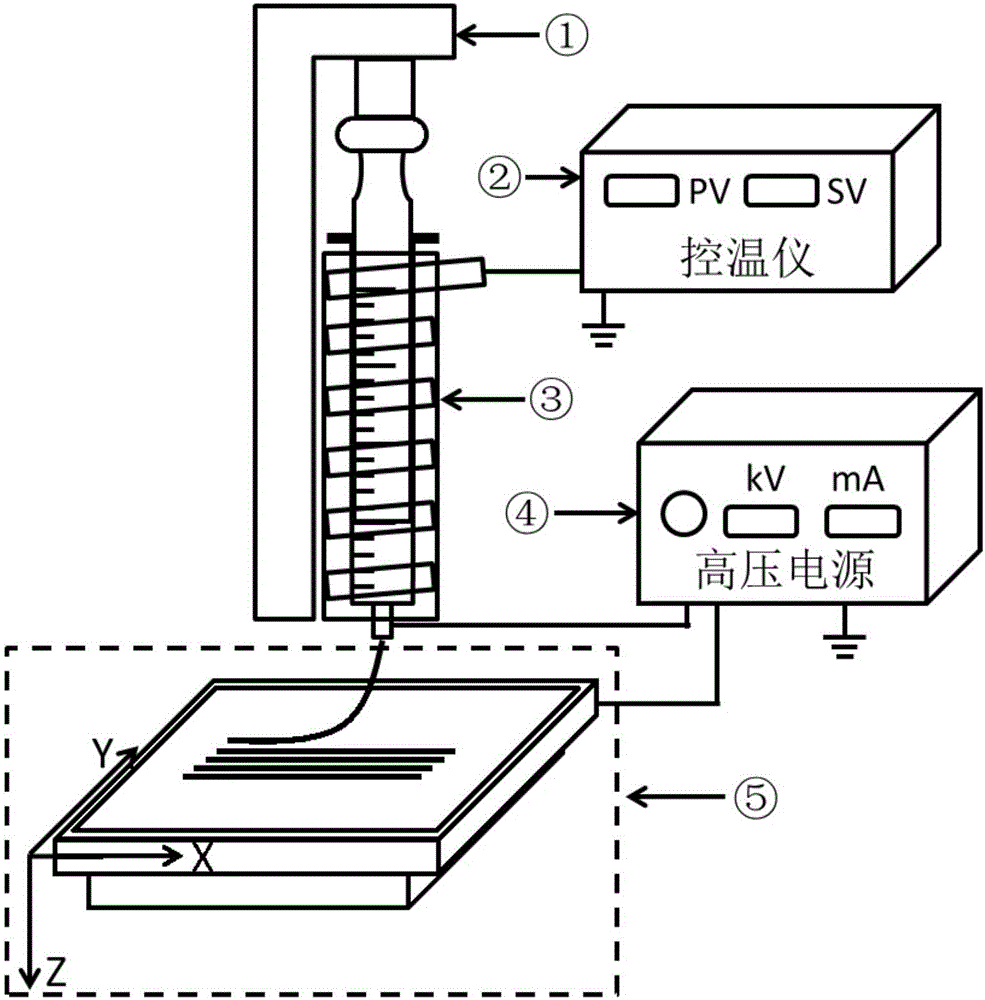

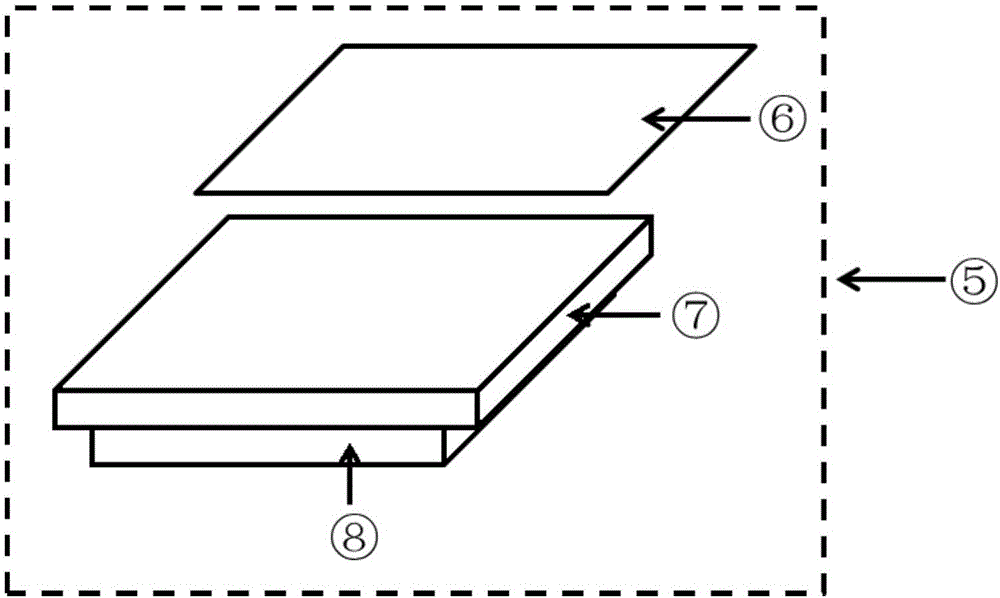

[0036] 1) Fix the insulating layer on the conductive receiving plate to form a new composite receiving plate. Then fix the composite receiving board on the XYZ motion system with a constant temperature control system, so that the composite receiving board can move arbitrarily along the XYZ axis.

[0037] 2) Put the polycaprolactone particles into a glass syringe with a stainless steel needle and heat it to 150°C to melt it, keep it for more than 4 hours and eliminate bubbles, place it on the bolus pump, and adjust the bolus rate to 0.9ml / h; The two ends of the high-voltage power supply are respectively connected to the needle and the conductive receiving plate, so that a high-voltage electric field is formed between the needle and the metal receiving plate; the distance between the composite receiving plate and the needle is adjusted to 5mm, so that the injected droplets are in the high-voltage electric field. Under the action, a tiny stream is for...

Example Embodiment

[0039] Specific embodiment two

[0040] 1) Fix the insulating layer on the conductive receiving plate to form a new composite receiving plate. Then fix the composite receiving board on the XYZ motion system with a constant temperature control system, so that the composite receiving board can move arbitrarily along the XYZ axis.

[0041] 2) Add polycaprolactone to hexafluoroisopropanol to dissolve to form a 15% solution, suck the solution into a 10ml syringe, place it on the bolus pump, adjust the bolus rate to 0.4mm / min; turn on the high-voltage power supply The two ends of the needle are respectively connected with the needle and the conductive receiving plate of the composite receiving plate, so that a high-voltage electric field is formed between the needle and the conductive receiving plate; the distance between the composite receiving plate and the needle is adjusted to 3mm, so that the droplets are injected Under the action of the high-voltage electric field, a tiny jet is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com