Industrialized production method of gas-phase synthesis of chlorosulfonic acid using pure sulfur trioxide

A technology of sulfur trioxide and gas phase synthesis, which is applied in the direction of sulfur trioxide/sulfuric acid, chlorosulfonic acid, sulfur-halogen-hydrogen-oxygen compounds, etc., which can solve the problems of high tail gas treatment costs, huge sulfuric acid absorption tower, and complicated maintenance, etc. problems, to achieve the effect of improving market competitiveness, reducing side reactions, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

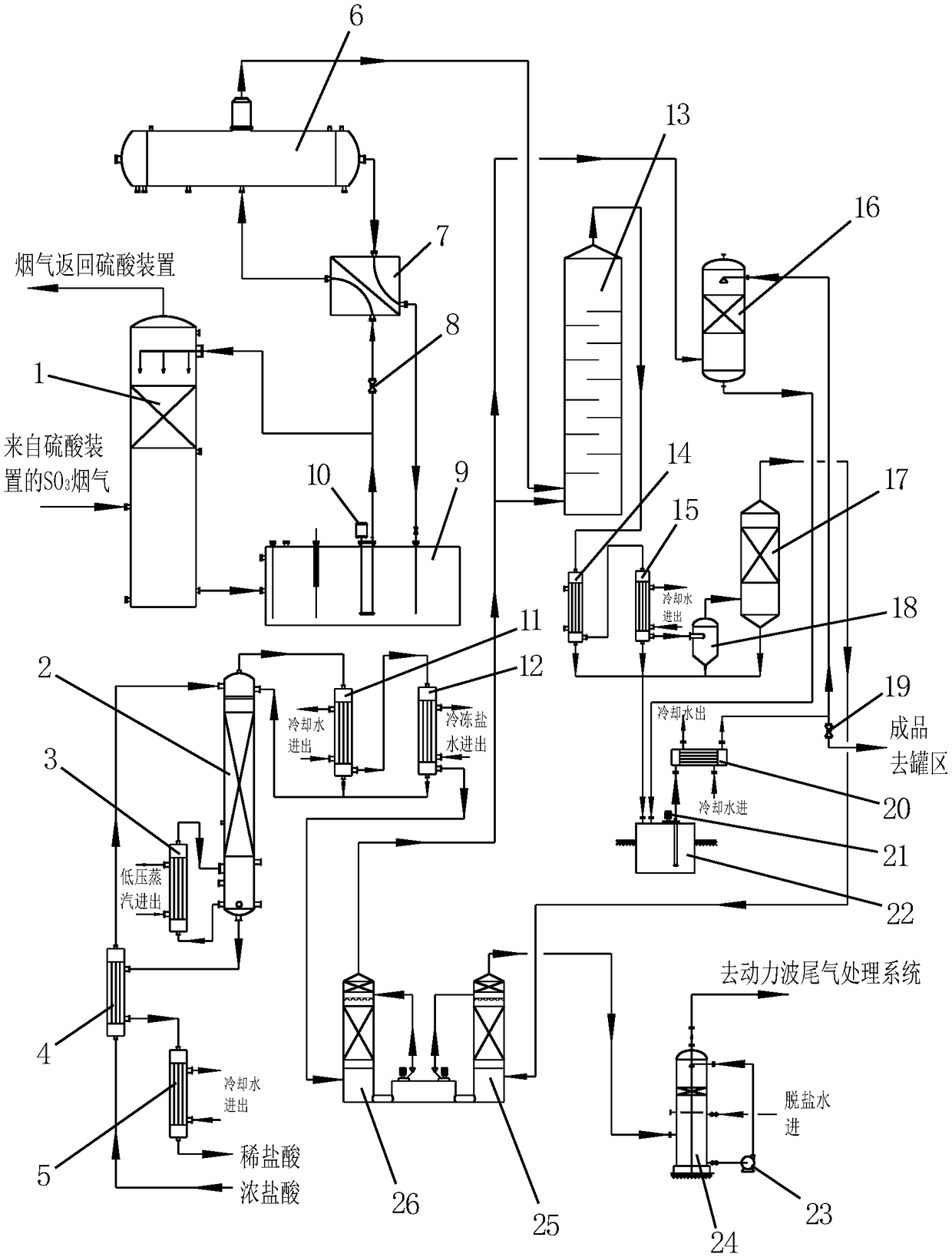

[0013] As shown in the figure, the used device of this industrial production method of gas-phase synthesis of chlorosulfonic acid with pure sulfur trioxide comprises nicotinic acid tower 1, desorption tower 2, reboiler 3, double-effect heat exchanger 4,5, Sulfur trioxide evaporator 6, spiral plate heat exchanger 7, nicotinic acid control valve 8, nicotinic acid circulation tank 9, first two-stage condenser 11, 12, chlorosulfonic acid synthesis tower 13, second two-stage condenser Devices 14, 15, auxiliary absorption tower 16, demister 17, cyclone separator 18, finished acid output valve 19, finished acid heat exchanger 20, chlorosulfonic acid finished product tank 22, water washing tower 24, water washing tower circulation pump 23 , pickling tower 25 and HCl scrubbing tower 26.

[0014] There is a sulfur trioxide raw material gas inlet in the middle part of the nicotinic acid tower 1, the oleum outlet of the lower part of the nicotinic acid tower is connected with the fuming s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com