A geometrical calibration method of a dish stirling solar dish column

A technology of geometric calibration and solar energy, applied in the direction of using feedback control, etc., can solve the problems of deviation tracking, installation error of dish support column, equipment unable to achieve sun tracking, etc., to achieve the effect of high efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the drawings.

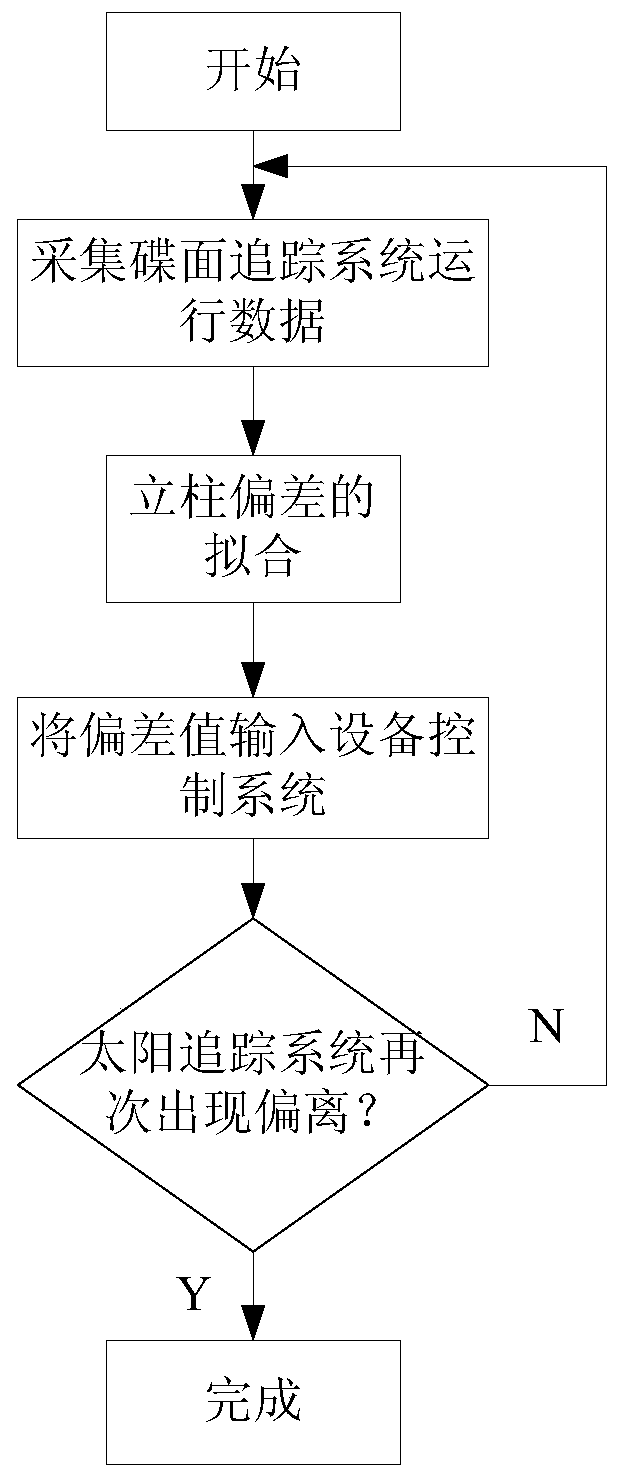

[0039] Reference figure 1 , A method for geometric calibration of the dish-type Stirling solar dish surface column, including the following steps:

[0040] 1) Collect operating data of the dish tracking system: After the equipment has the power generation conditions, the operator forces the equipment to start the sun tracking system and the power generation system, and collect the sun position data in the sun tracking system and the actual sun track data. If deviation from tracking occurs during data collection, the system is forced to start again until the data collection is completed. The collection process requires at least 3 hours of power generation operation data.

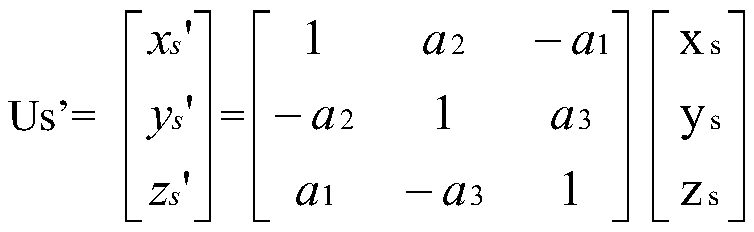

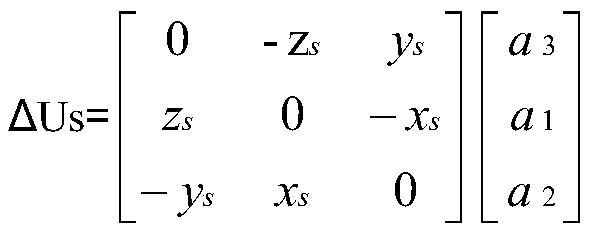

[0041] 2) Column deviation fitting: The fitting of column deviation essentially refers to the transformation relationship between the coordinate system of the tracking system and the ground coordinate system. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com